Sep 17,2025

FSW Liquid Cooling Plate Technology Driving Next-Generation Thermal Management

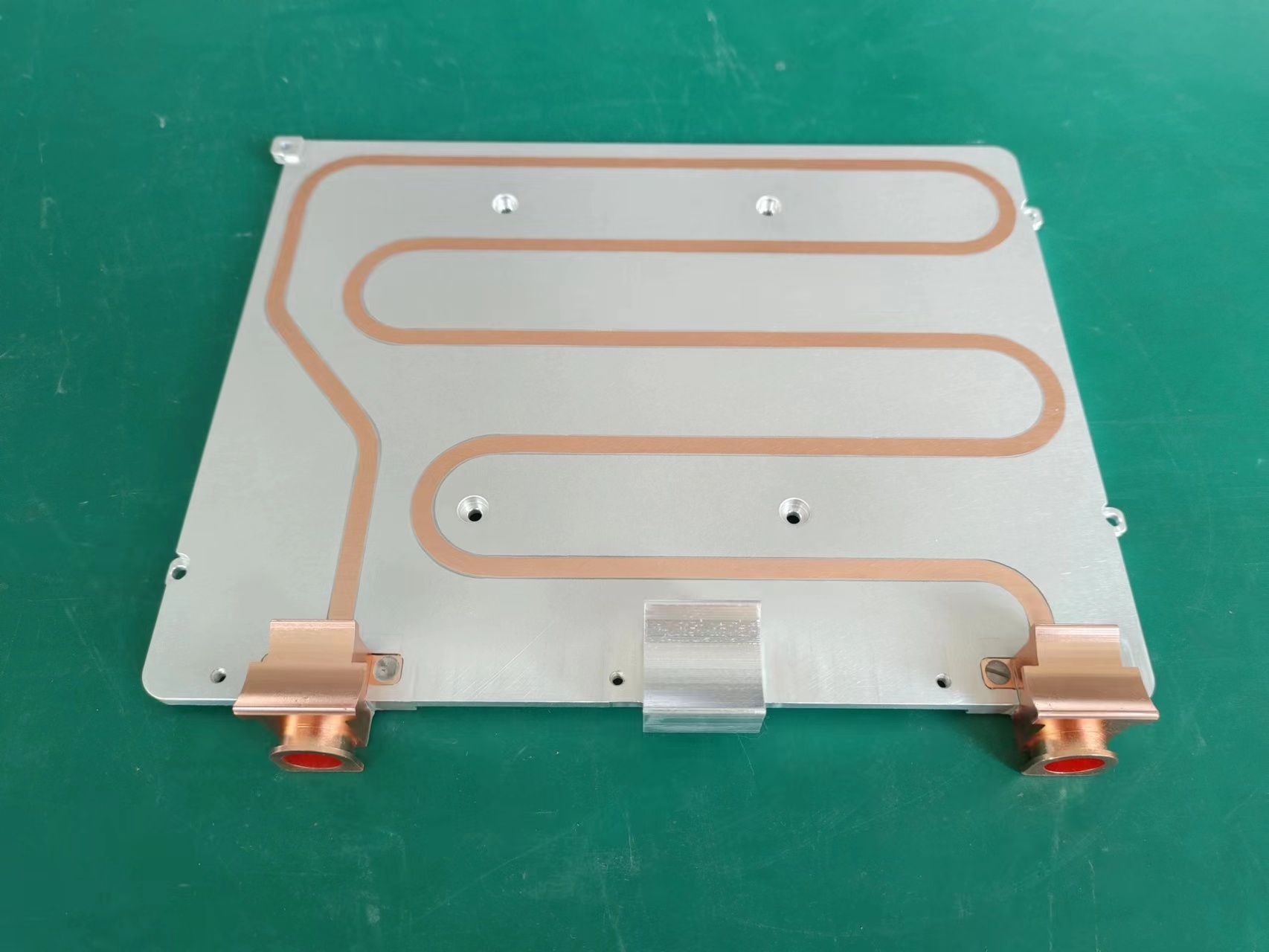

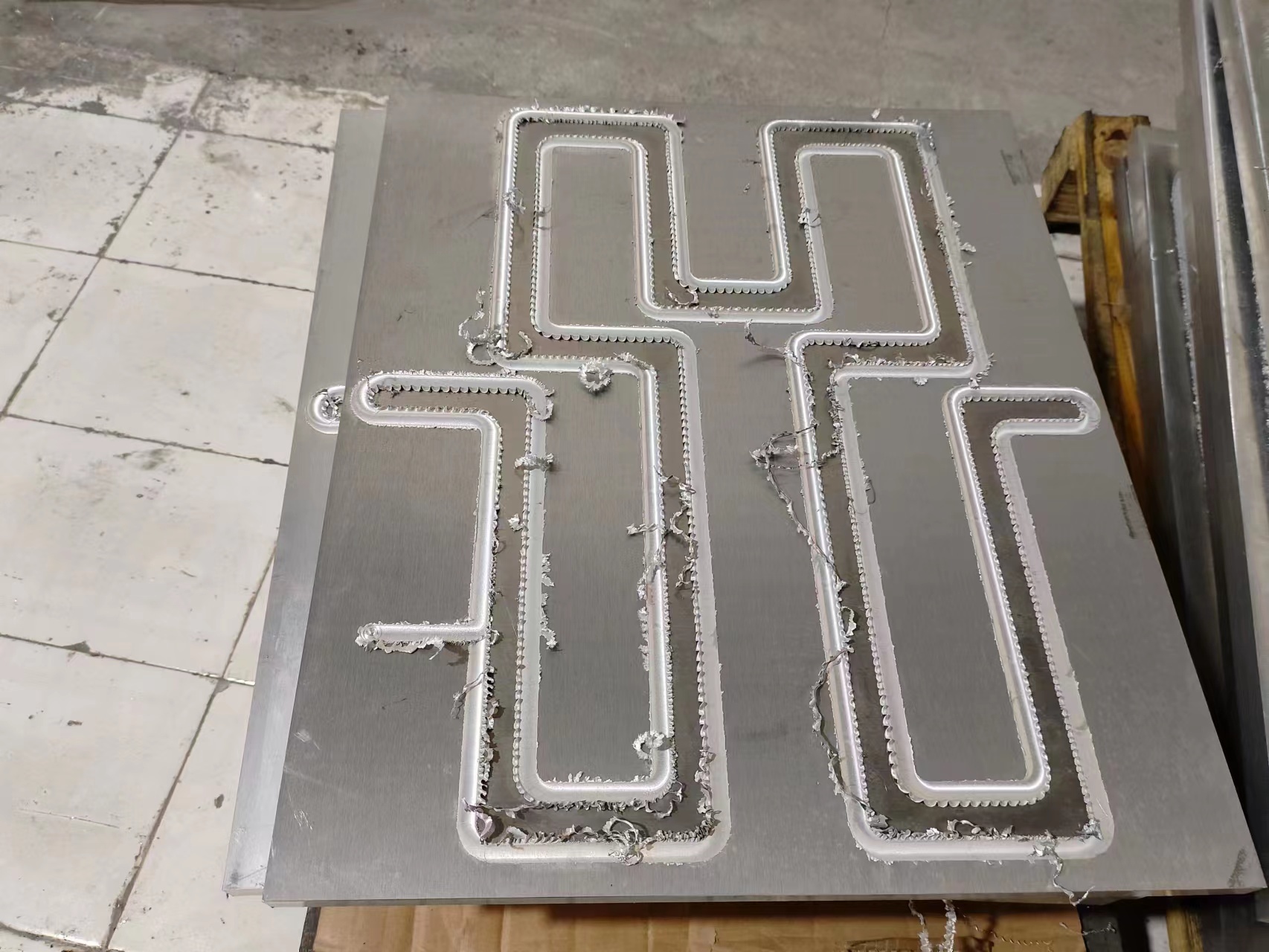

Innovation in Cooling Solutions The rapid advancement of electronics and electric vehicles has created a growing demand for efficient thermal management systems. Among the most promising solutions, the FSW Liquid Cooling Plate has emerged as a game-changer. Using friction stir welding (FSW) technology,

Sep 08,2025

IGBT Liquid Cold Plates Revolutionize Thermal Management

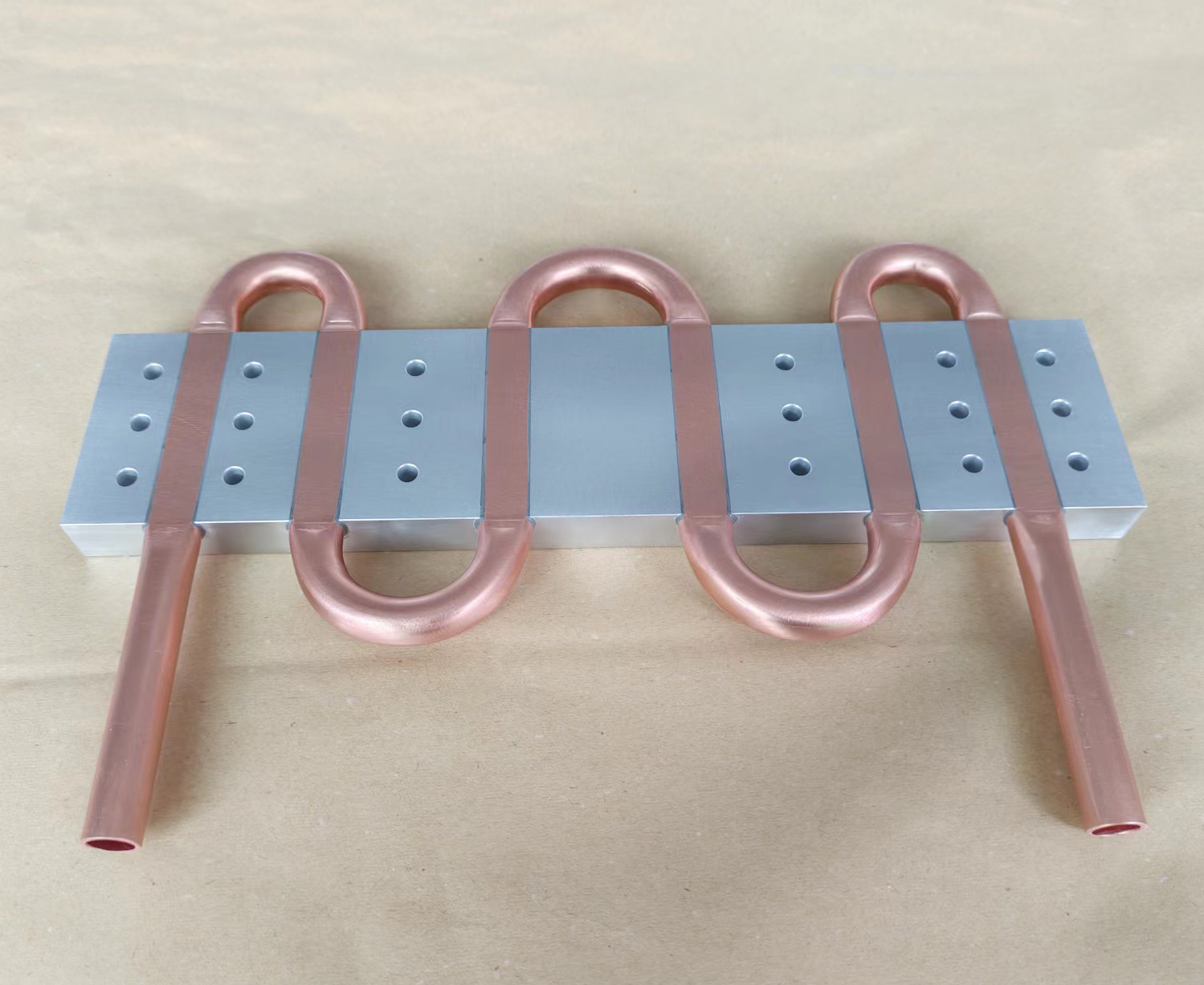

In the rapidly evolving world of power electronics, thermal management has emerged as a critical bottleneck for performance and reliability. At the heart of this challenge lies the Insulated Gate Bipolar Transistor (IGBT), a cornerstone component in applications ranging from electric vehicles (EVs) and renewable energy systems to industrial motor drives. As power densities soar, traditional air cooling is proving insufficient. Enter the IGBT Liquid Cold Plate—a sophisticated thermal solution that is rapidly becoming the industry standard for managing intense heat loads.

Sep 01,2025

The Rising Dominance of IGBT Liquid Cold Plates in High-Power Electronics

The relentless push for higher power density and efficiency in electronics is driving a thermal management revolution. At the heart of this transformation is the IGBT Liquid Cold Plate, a sophisticated cooling solution rapidly becoming indispensable in industries ranging from electric vehicles (EVs) to renewable energy and industrial automation.

Aug 25,2025

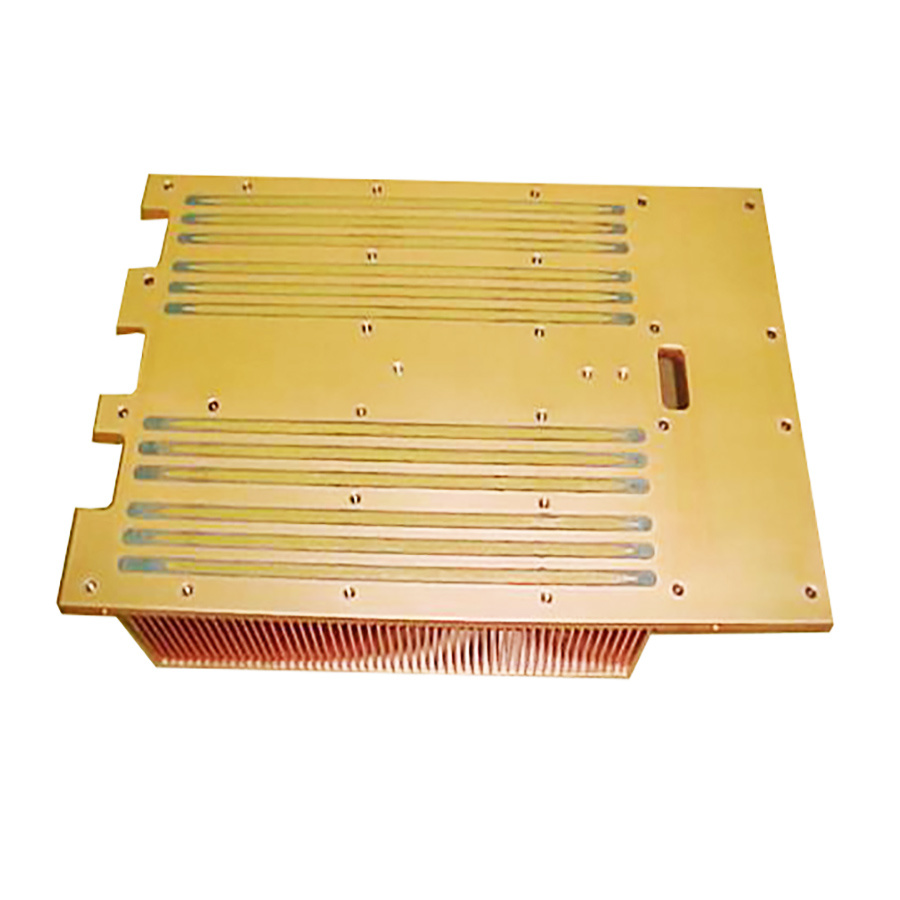

Inverter Skived Heat Sink Driving Efficiency in Power Electronics

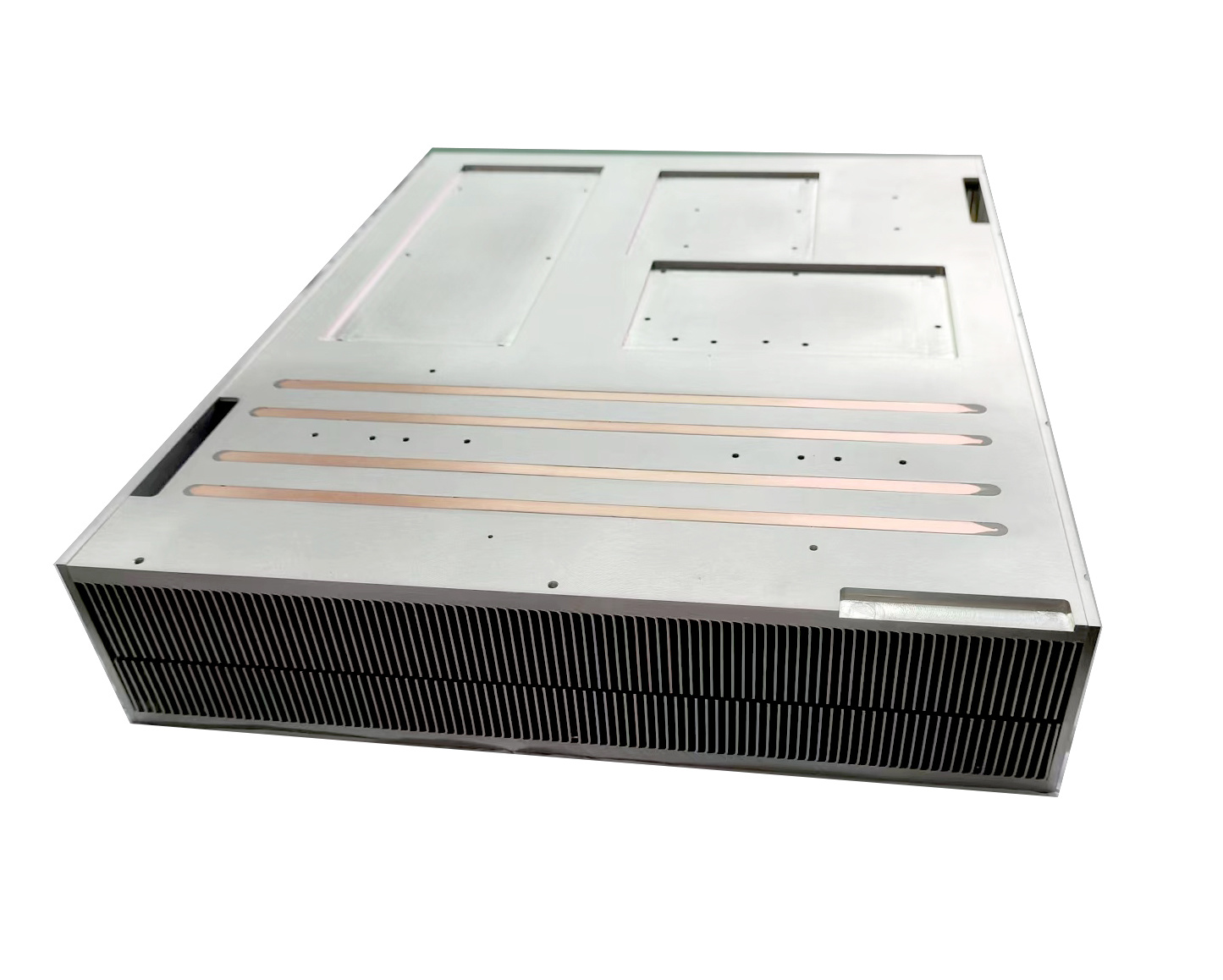

In today’s rapidly advancing electronics industry, efficient thermal management solutions have become the backbone of reliable performance. One of the most significant developments gaining attention is the inverter skived heat sink, a cutting-edge innovation designed to address the growing demand for compact, durable, and highly effective cooling systems.

Aug 22,2025

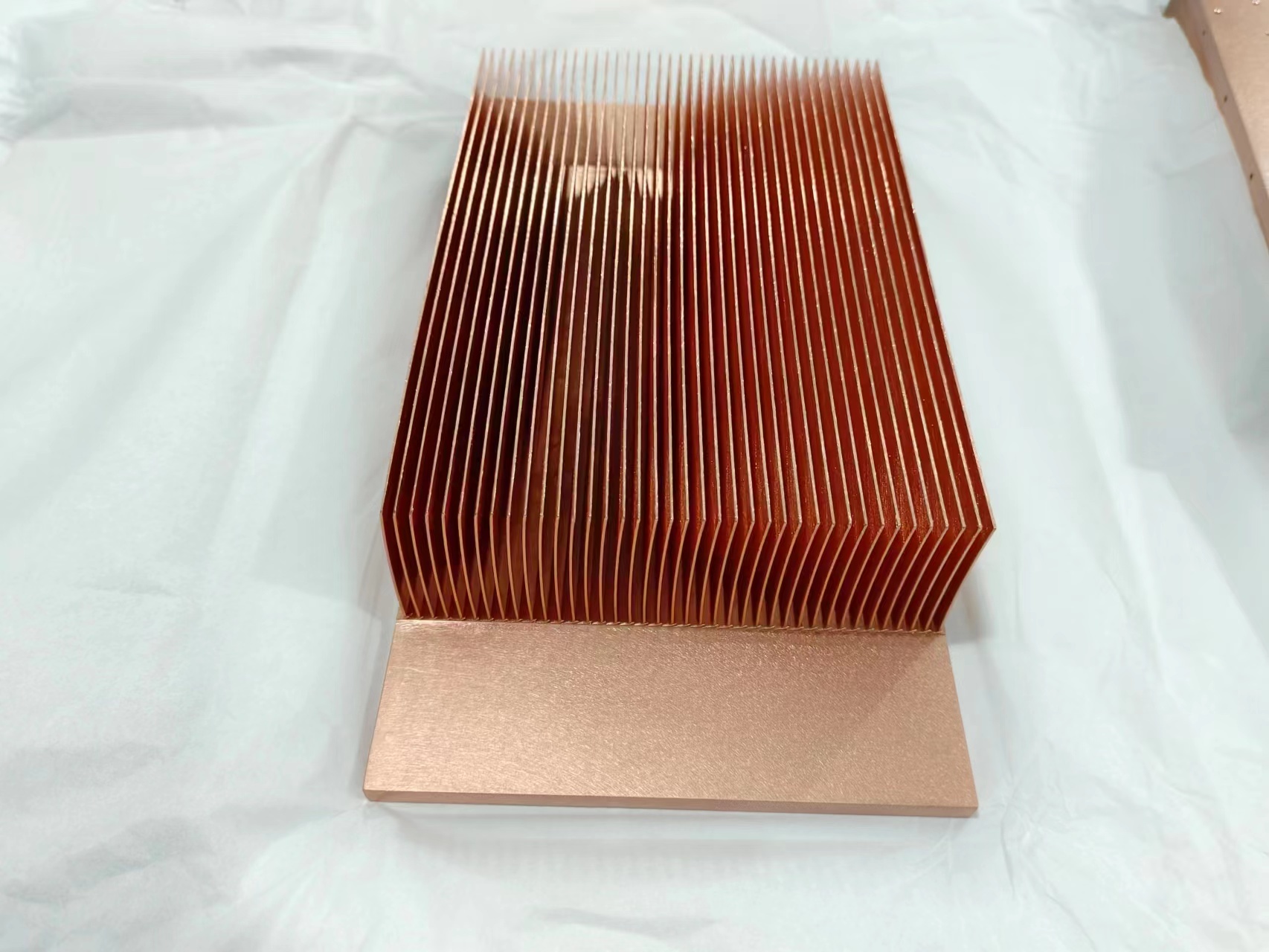

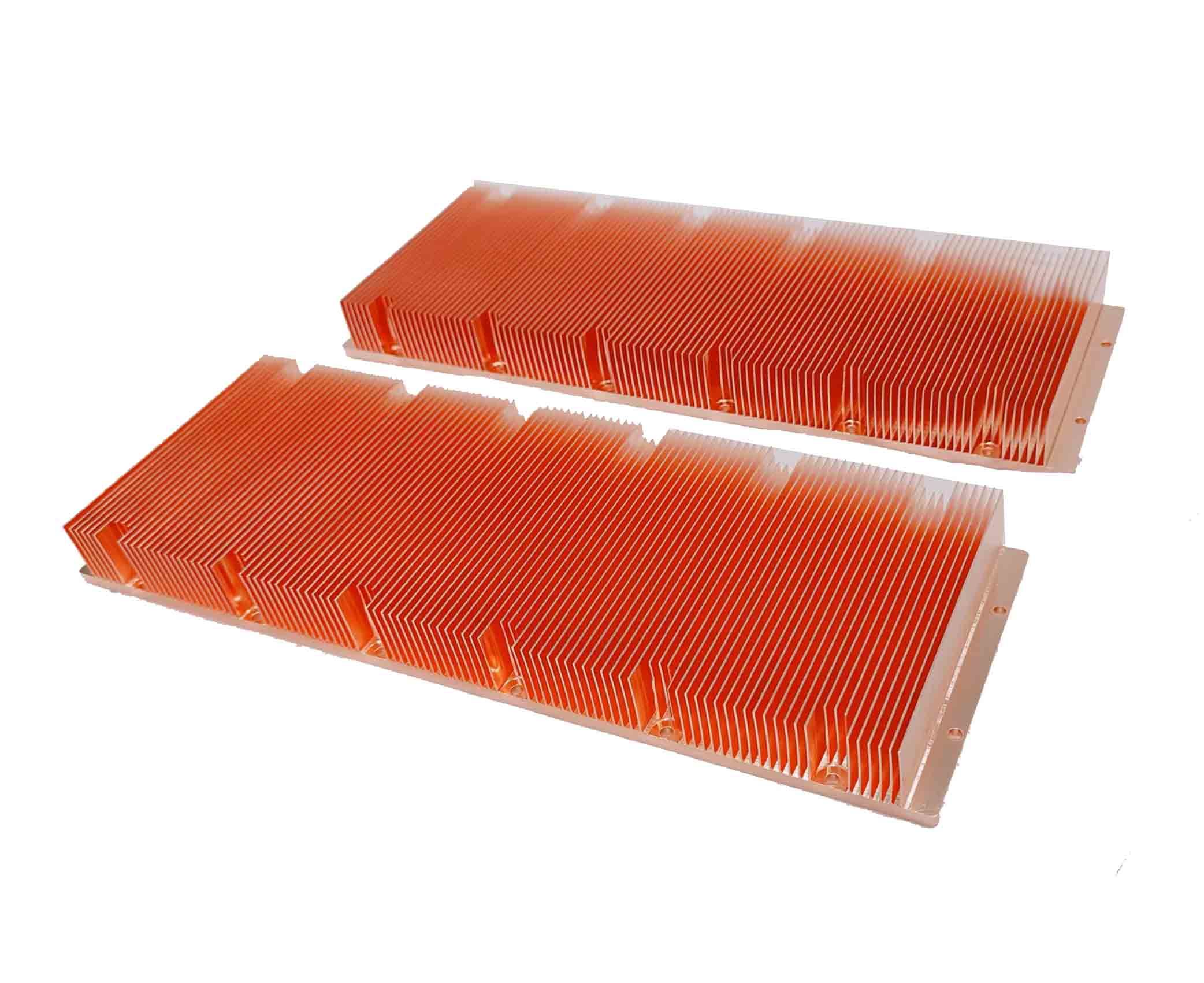

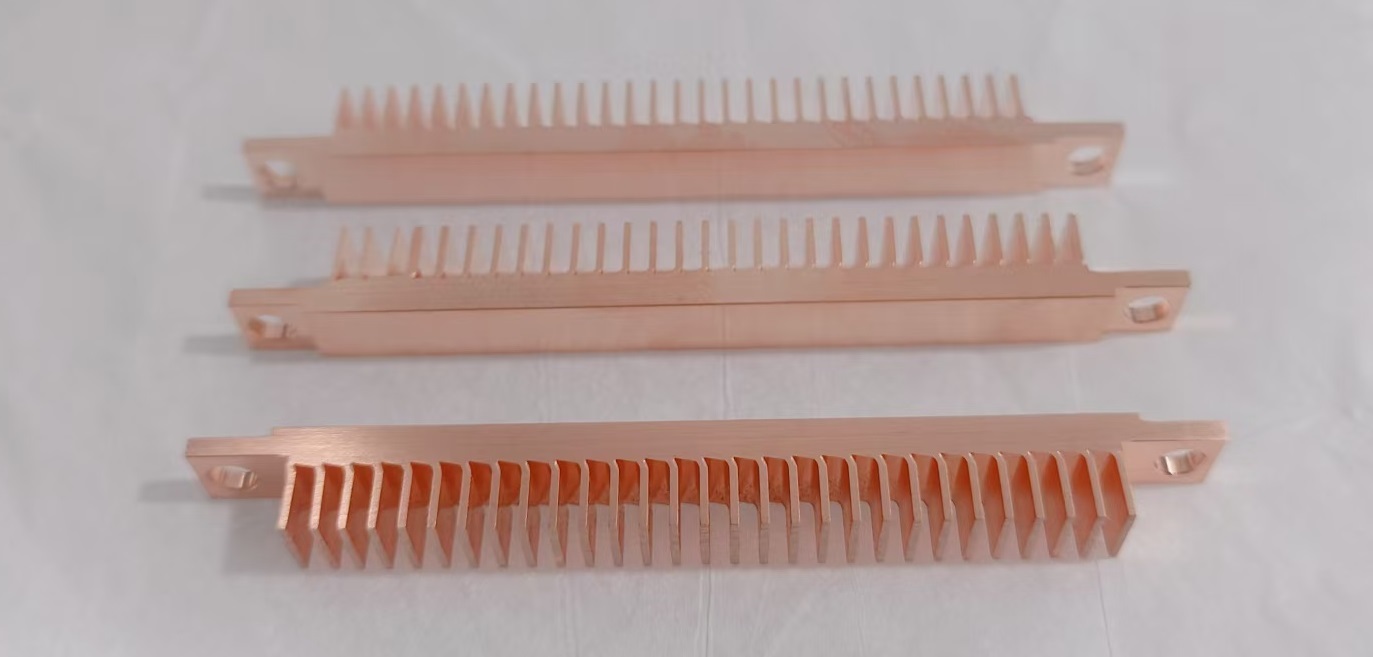

A Skived Fin Heat Sink is one of the most advanced cooling solutions used in modern electronic and industrial systems. Manufactured through a precision skiving process, this heat sink is created by shaving thin layers of material from a metal block to form high-density fins.

Aug 18,2025

Skived Fin Heat Sink Revolutionizes Thermal Management in Electronics

The demand for efficient thermal management solutions in modern electronics has never been higher. Enter the Skived Fin Heat Sink, a cutting-edge technology that is transforming how devices dissipate heat. With its superior thermal performance and compact design, the Skived Fin Heat Sink is becoming the go-to choice for industries ranging from consumer electronics to aerospace.

Aug 12,2025

Innovative Inverter Skived Heat Sink Technology Revolutionizes Thermal Management in Electronics

In the rapidly evolving world of electronics, thermal management remains a critical challenge, especially for high-power applications like inverters. A breakthrough solution has emerged in the form of the inverter skived heat sink, a cutting-edge technology designed to enhance cooling efficiency and reliability. This innovative approach is gaining traction across industries, from electric vehicles to renewable energy systems, where effective heat dissipation is paramount.

Jul 30,2025

The Rise of Friction Stir Welded Cold Plates

In the ever-evolving world of thermal management solutions, Friction Stir Welded Cold Plates are emerging as a game-changer for industries ranging from aerospace to electric vehicles. This innovative technology combines the durability of friction stir welding (FSW) with the efficiency of cold plates, creating a robust solution for heat dissipation in high-performance applications.

Jul 21,2025

Discover premium copper skiving heatsink for motherboard cooling efficiency

Premium copper skiving heatsinks are a must for anyone serious about motherboard cooling—whether building a high-performance gaming PC or ensuring server reliability.

Jul 02,2025

High-Precision Temperature Control Chiller Liquid Cooling Plate for Photoresist Production

A stainless steel tube water cooling plate using casting technology application for High-Precision Temperature Control Chiller Liquid Cooling Plate for Photoresist Production

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?