Innovative Inverter Skived Heat Sink Technology Revolutionizes Thermal Management in Electronics

In the rapidly evolving world of electronics, thermal management remains a critical challenge, especially for high-power applications like inverters. A breakthrough solution has emerged in the form of the inverter skived heat sink, a cutting-edge technology designed to enhance cooling efficiency and reliability. This innovative approach is gaining traction across industries, from electric vehicles to renewable energy systems, where effective heat dissipation is paramount.

What is an Inverter Skived Heat Sink?

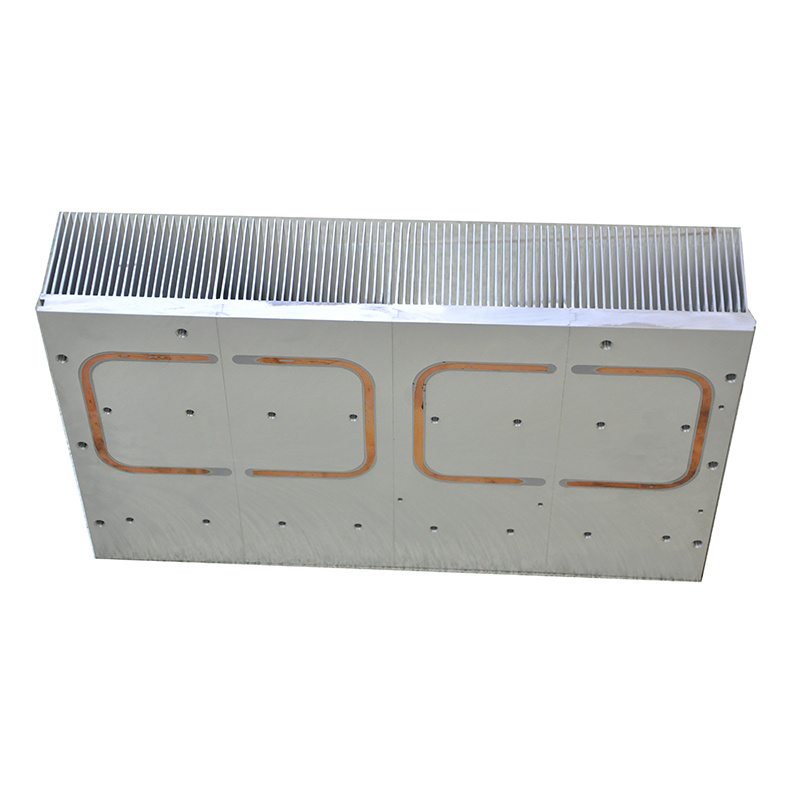

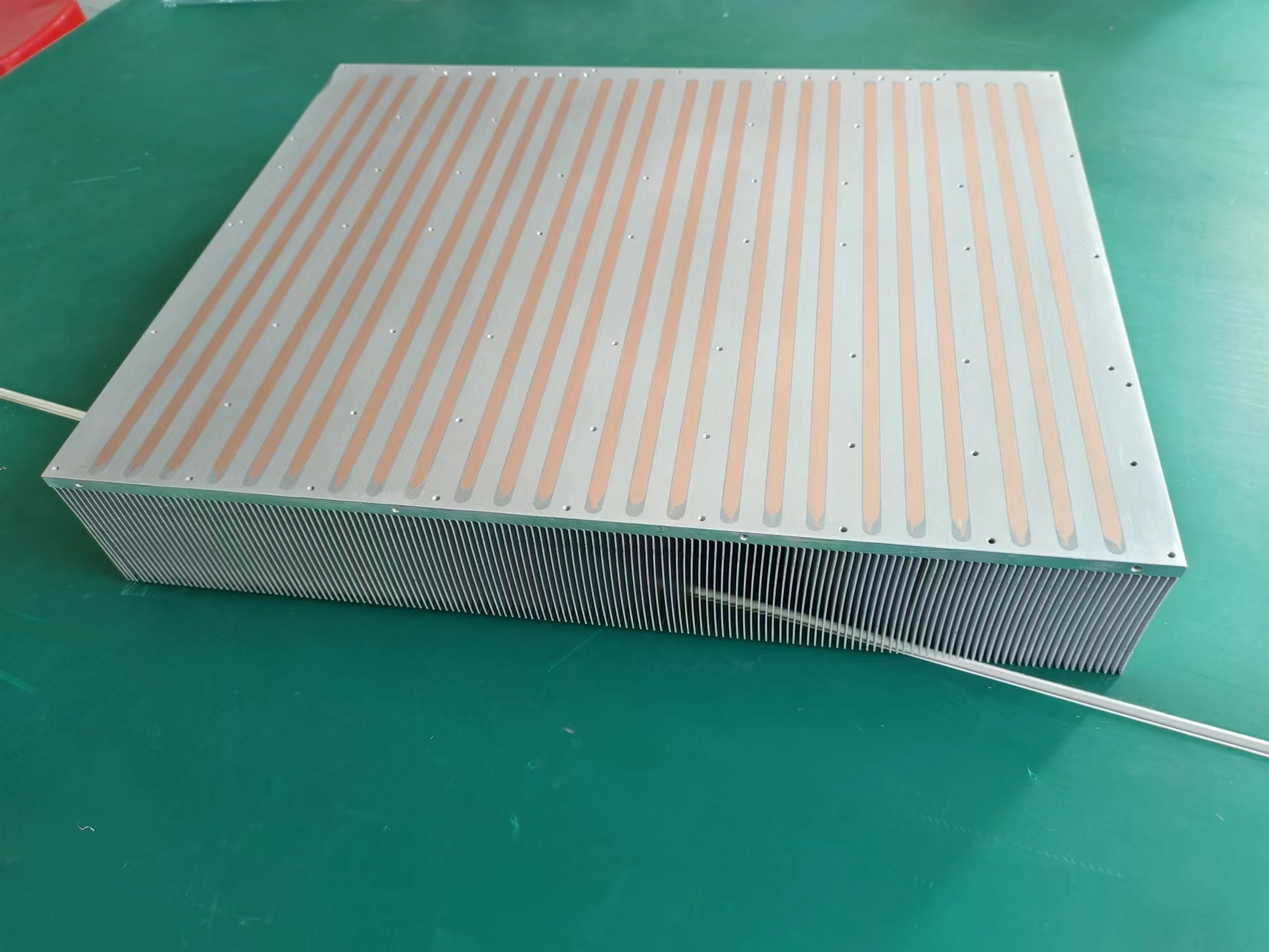

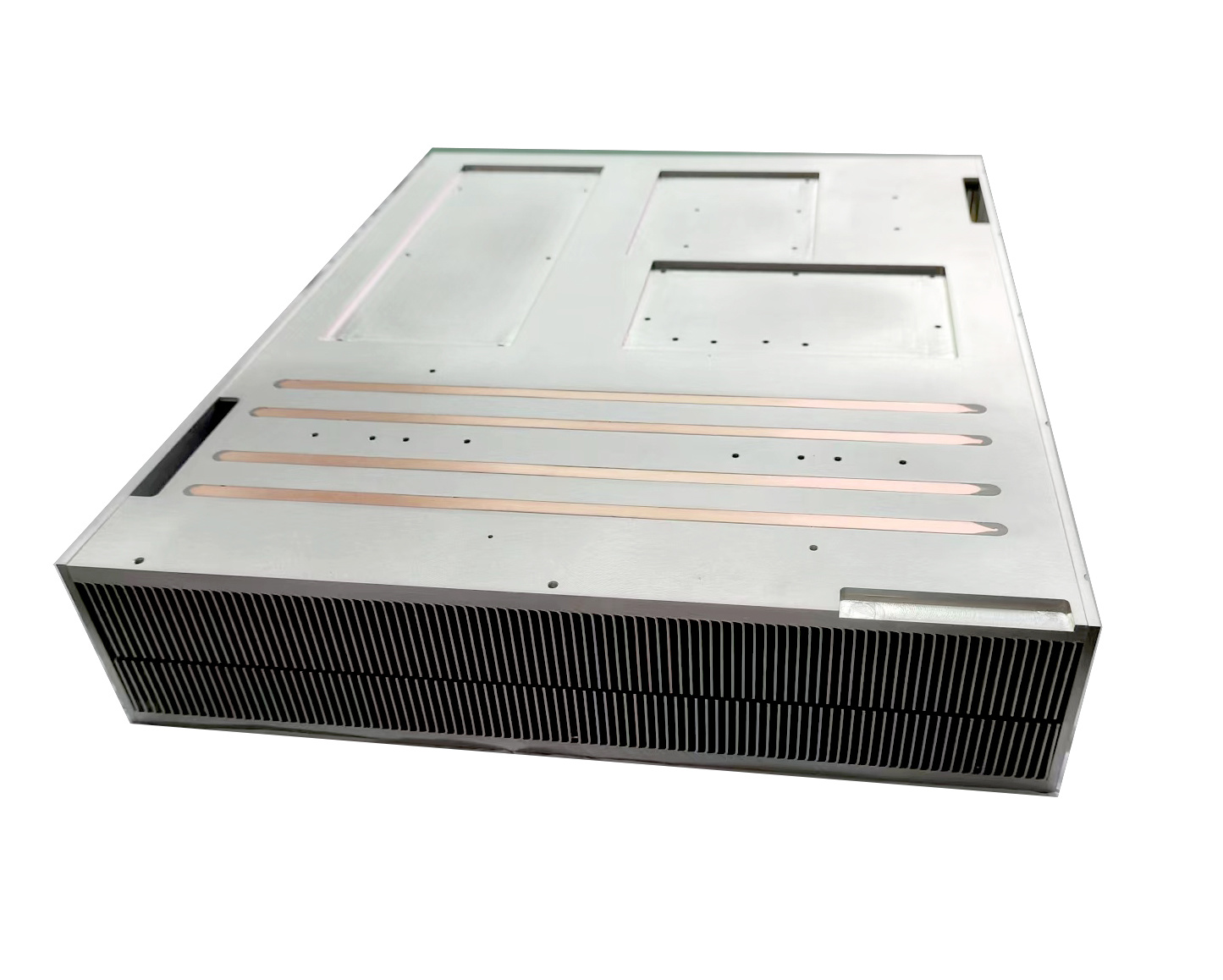

A skived heat sink is a high-performance cooling component manufactured using a precision skiving process. This technique involves shaving thin, uniform fins from a solid block of metal, typically aluminum or copper, to create a dense array of cooling surfaces. When applied to inverters—devices that convert DC power to AC—the inverter skived heat sink offers superior thermal conductivity and heat dissipation compared to traditional extruded or bonded heat sinks.

Why Skived Heat Sinks for Inverters?

Inverters generate significant heat during operation, which can degrade performance and lifespan if not properly managed. The inverter skived heat sink excels in this regard due to its unique design:

High Fin Density: The skiving process allows for ultra-thin, closely spaced fins, maximizing surface area for heat transfer.

Lightweight & Compact: Despite their efficiency, skived heat sinks are lightweight, making them ideal for space-constrained applications.

Customizable Designs: Manufacturers can tailor the inverter skived heat sink to specific thermal and mechanical requirements, ensuring optimal performance.

Industry Applications

The adoption of inverter skived heat sink technology is growing across multiple sectors:

Electric Vehicles (EVs): Inverters in EVs require robust cooling to handle high power loads. Skived heat sinks ensure reliability and longevity.

Renewable Energy: Solar and wind power systems rely on inverters to feed energy into grids. Efficient thermal management is critical for sustained operation.

Industrial Electronics: High-power industrial equipment benefits from the enhanced cooling capabilities of skived heat sinks.

Future Outlook

As demand for energy-efficient and compact electronics rises, the inverter skived heat sink is poised to become a standard in thermal management. Advances in materials and manufacturing techniques will further refine its performance, solidifying its role in next-generation electronics.

In conclusion, the inverter skived heat sink represents a significant leap forward in cooling technology, addressing the thermal challenges of modern inverters with unmatched efficiency. Its widespread adoption underscores its importance in shaping the future of electronics.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?