The Rise of Friction Stir Welded Cold Plates

In the ever-evolving world of thermal management solutions, Friction Stir Welded Cold Plates are emerging as a game-changer for industries ranging from aerospace to electric vehicles. This innovative technology combines the durability of friction stir welding (FSW) with the efficiency of cold plates, creating a robust solution for heat dissipation in high-performance applications.

What Are Friction Stir Welded Cold Plates?

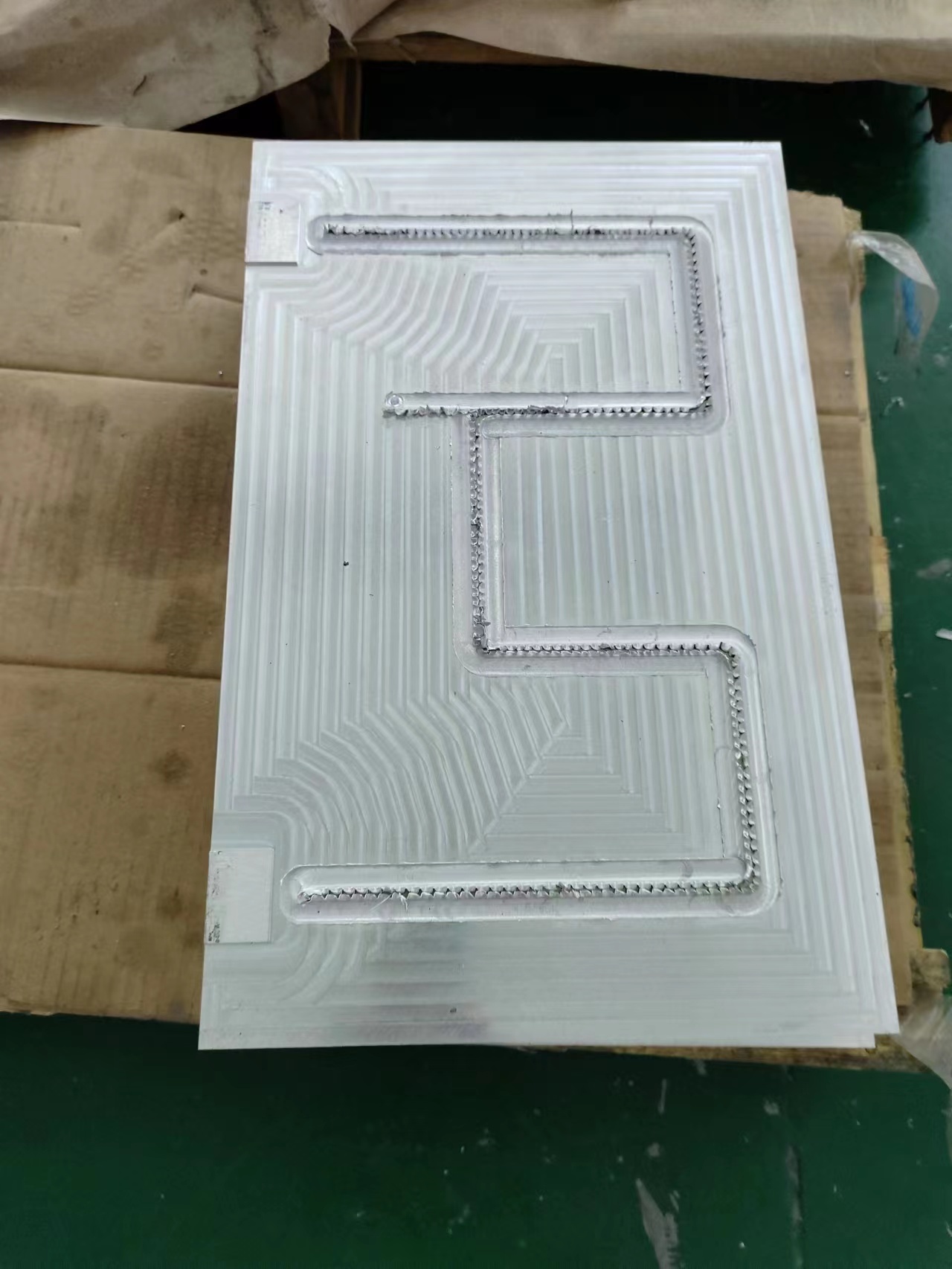

Friction Stir Welded Cold Plates are advanced heat exchangers designed to cool electronic components, batteries, and power systems. Unlike traditional welding methods, FSW uses a rotating tool to generate frictional heat, bonding materials without melting them. This results in stronger, defect-free joints, making Friction Stir Welded Cold Plates ideal for critical applications where thermal conductivity and structural integrity are paramount.

Advantages Over Conventional Methods

The key benefit of Friction Stir Welded Cold Plates lies in their superior thermal performance and longevity. Traditional cold plates often suffer from weak joints or corrosion over time, but FSW ensures a seamless bond between materials like aluminum or copper. This not only enhances heat transfer but also reduces the risk of leaks—a common issue in liquid cooling systems.

Moreover, Friction Stir Welded Cold Plates are lighter and more compact, making them perfect for weight-sensitive industries such as electric aviation and space technology. Companies like SpaceX and Tesla are reportedly exploring this technology to improve the efficiency of their battery thermal management systems.

Industry Adoption and Future Prospects

Major manufacturers are rapidly adopting Friction Stir Welded Cold Plates due to their reliability and cost-effectiveness. According to a recent report by MarketsandMarkets, the global FSW market is projected to grow by 8.5% annually, with cold plates being a significant contributor.

As industries push the boundaries of innovation, Friction Stir Welded Cold Plates are poised to become the gold standard in thermal management. With ongoing research into new materials and designs, their applications could soon expand to renewable energy systems and advanced robotics.

In conclusion, the rise of Friction Stir Welded Cold Plates marks a pivotal moment in engineering—a fusion of strength, efficiency, and sustainability that promises to redefine cooling technologies for decades to come.

PREVIOUS:

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?