Nov 24,2025

Step up your thermal performance with our high-efficiency Bonded Fin Heat Sink, the ultimate solution for managing heat in compact, high-power applications. Unlike conventional methods, the Bonded Fin Heat Sink design combines a solid base with a dense array of thin fins, creating an optimal balance between mass

Nov 03,2025

Bonded Fin Heat Sink Technology

In the rapidly evolving world of electronics, efficient thermal management solutions are crucial for ensuring the performance and longevity of devices. Among the most promising technologies in this area is the Bonded Fin Heat Sink, which offers a new level of efficiency and design flexibility.

Oct 28,2025

The Rising Demand for Bonded Fin Heat Sink Solutions

As electronic devices become increasingly powerful and compact, the challenge of effective thermal management has never been greater. Leading the charge in cooling solutions is the advanced Bonded Fin Heat Sink technology, which is setting new standards for performance and design flexibility in industries from computing to electric vehicles.

Oct 24,2025

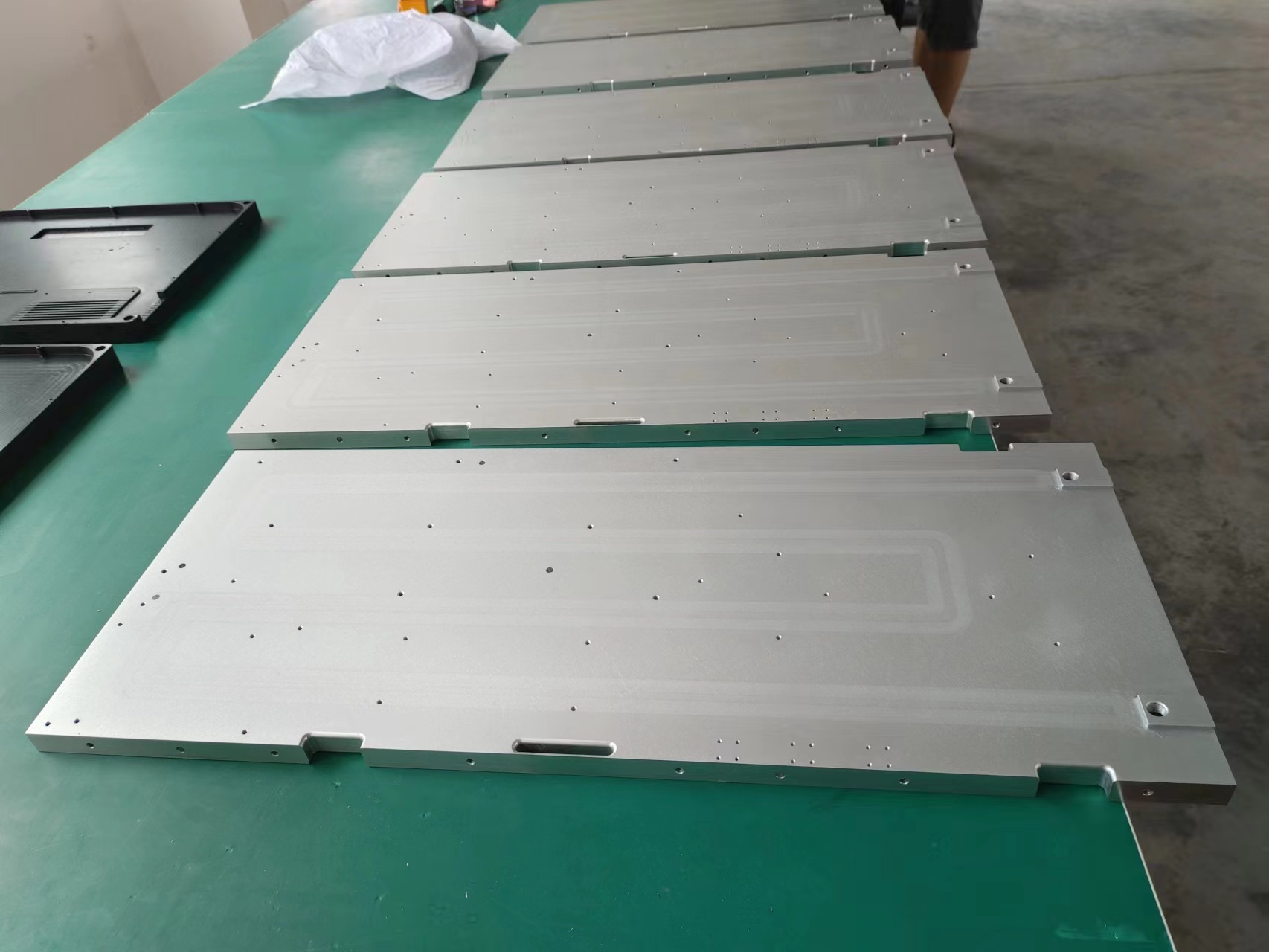

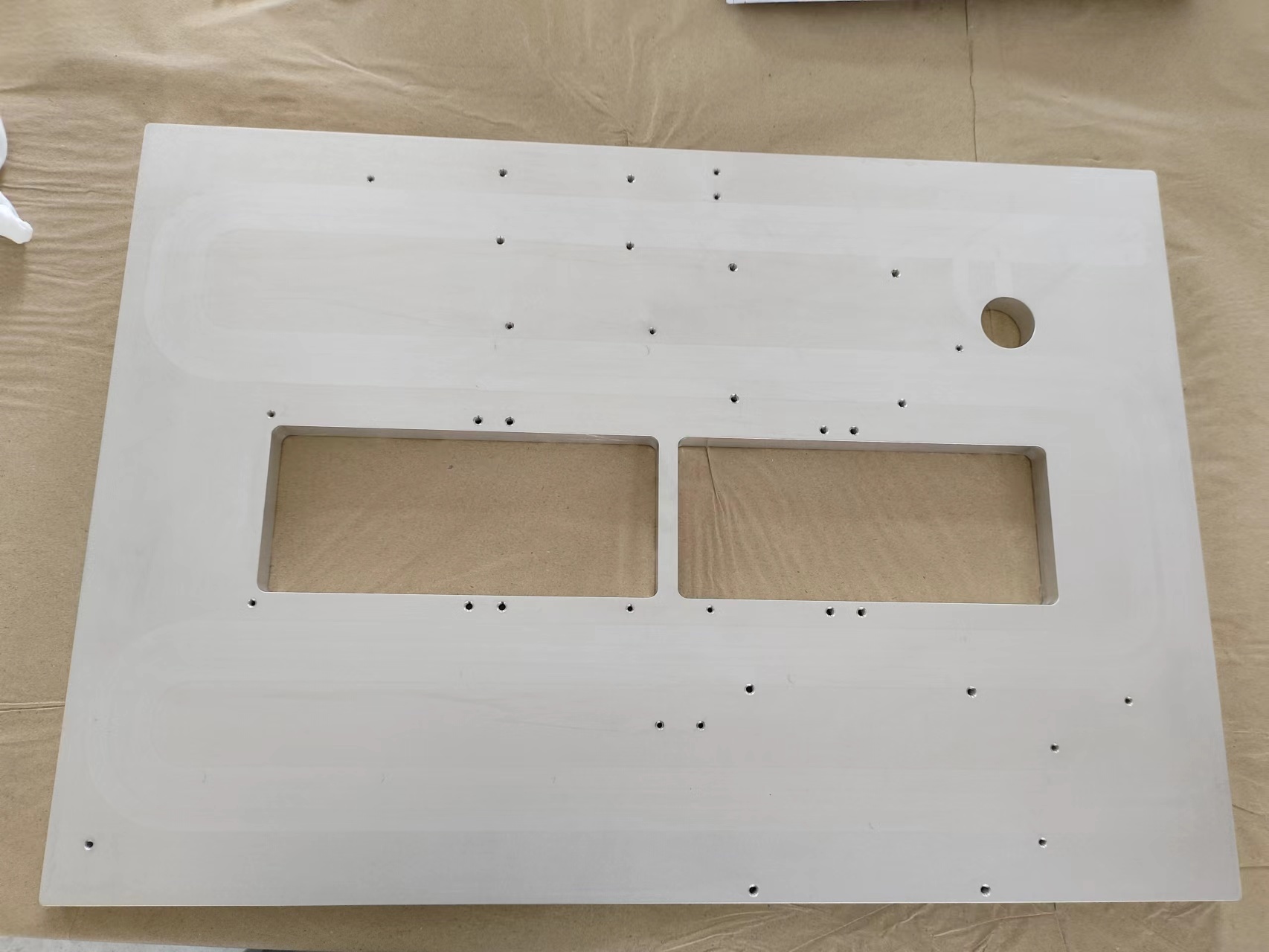

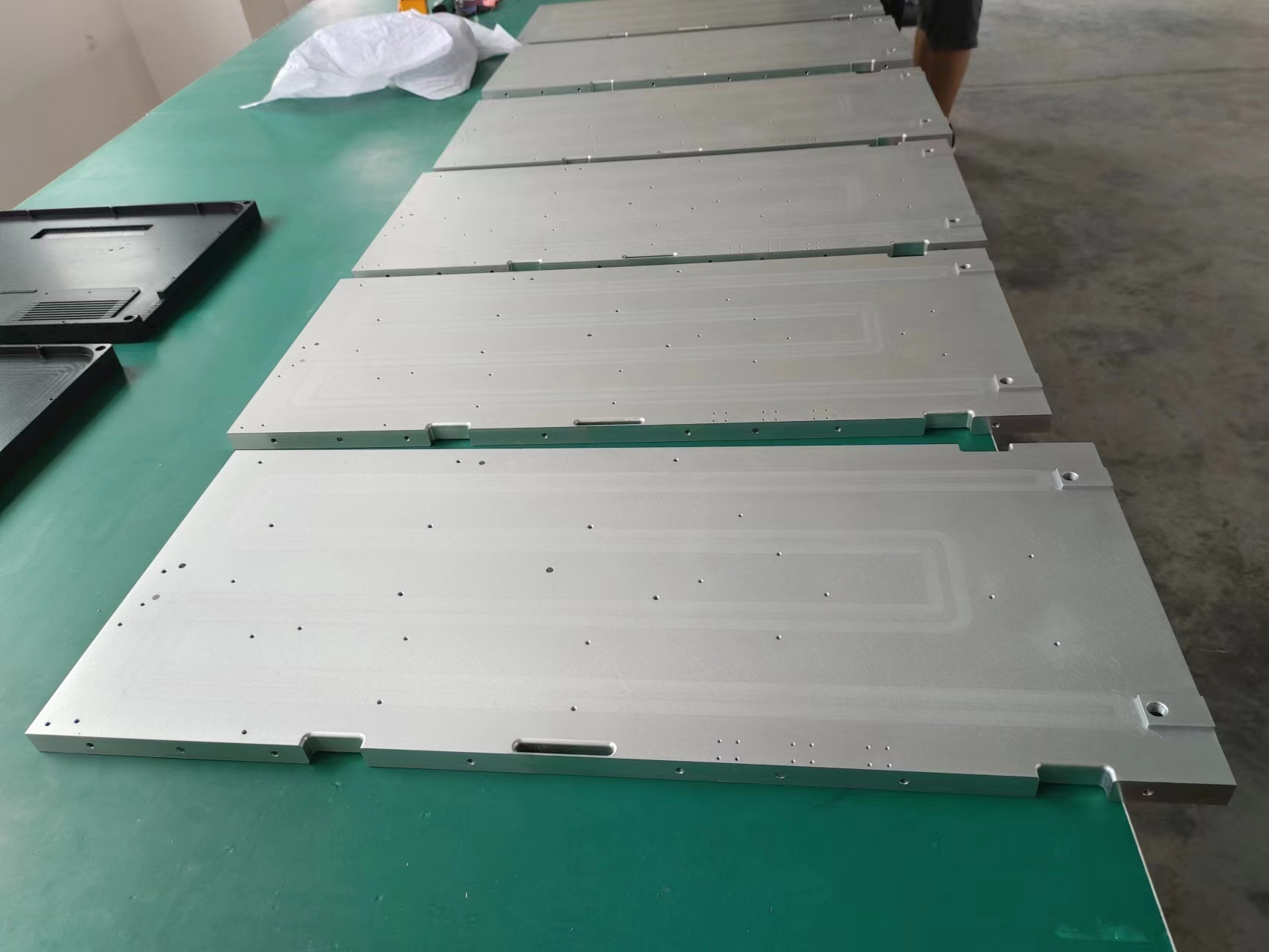

Quality Friction Stir Welded Cold Plates

Our Friction Stir Welded Cold Plates represent a breakthrough in thermal management for high-power electronics. Utilizing the solid-state Friction Stir Welding process, we create incredibly robust and reliable internal fluid channels.

Oct 20,2025

How Friction Stir Welded Cold Plates Conquer High Power Densities

In the rapidly evolving world of electronics, where power densities continue to climb, effective thermal management is no longer a luxury but a critical necessity. A key component rising to meet this challenge is the Friction Stir Welded Cold Plates, a product whose manufacturing process is revolutionizing heat exchanger reliability and efficiency.

Oct 14,2025

Friction Stir Welded Cold Plates Gain Traction in Electronics Cooling

The demand for efficient thermal management solutions in high-power electronics is driving adoption of advanced manufacturing techniques, notably in the production of cold plates. A significant trend emerging is the increasing use of Friction Stir Welded cold plates, a method that promises superior performance over traditional joining techniques like brazing or fusion welding.

Oct 10,2025

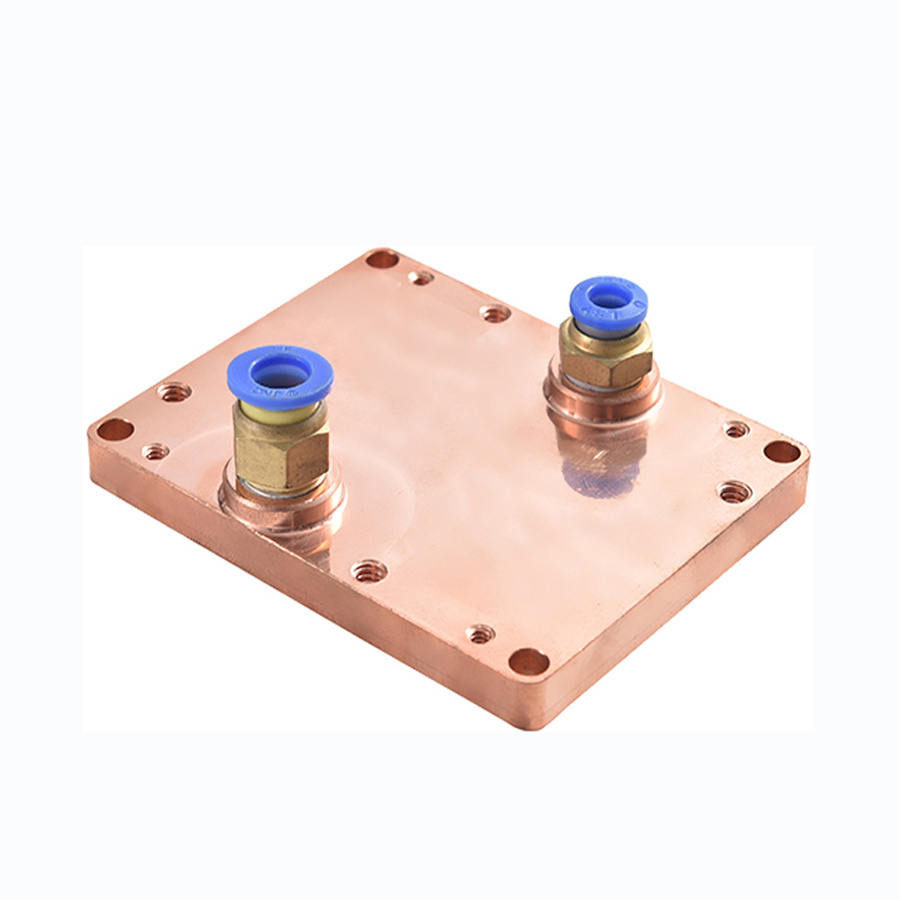

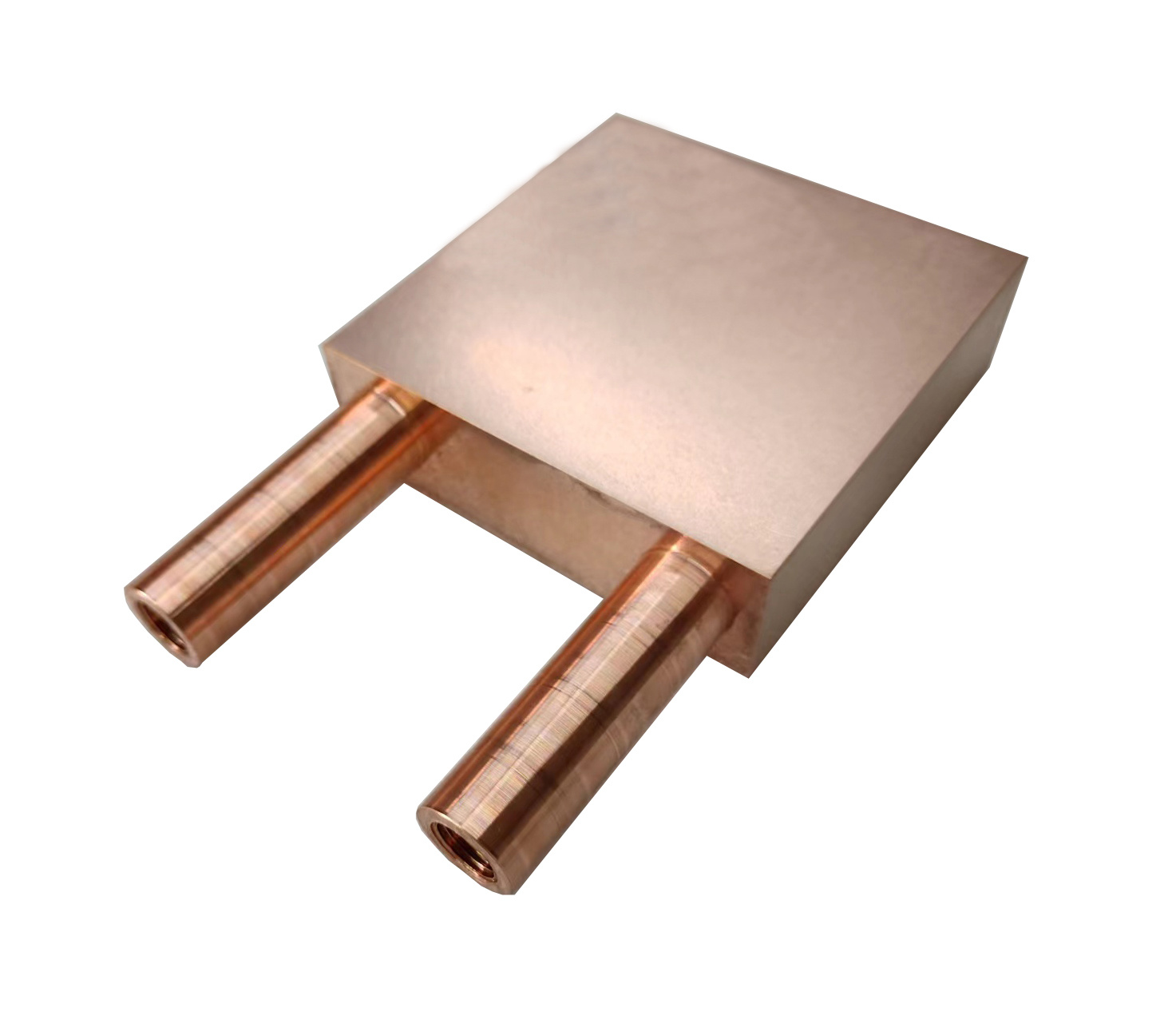

Brazed Liquid Cold Plates Revolutionize Thermal Management

The thermal management industry is witnessing a significant shift with the advanced capabilities of the Brazed Liquid Cold Plate. This technology is becoming the cornerstone for cooling high-power electronics in sectors like electric vehicles, data centers, and renewable energy systems. Unlike traditional cooling methods, a Brazed Liquid Cold Plate offers superior thermal conductivity and reliability, making it a preferred solution for engineers

Sep 28,2025

Advanced Brazed Liquid Cold Plate Technology Powers Next-Generation Electronics Thermal Management

The relentless drive for higher performance in electronics, from data center servers to electric vehicle power converters, is generating unprecedented thermal challenges. In response, the industry is increasingly turning to advanced cooling solutions, with the Brazed Liquid Cold Plate emerging as a critical technology. Unlike traditional cooling methods, a Brazed Liquid Cold Plate offers superior thermal conductivity and reliability, making it indispensable for managing intense heat fluxes.

Sep 25,2025

Quality Fsw Liquid Cooling Plate

Experience the next generation of liquid cooling with our high-performance FSW Liquid Cooling Plate. Designed for applications where thermal management is critical,

Sep 22,2025

The Rise of FSW Liquid Cooling Plate Technology

The landscape of thermal management is undergoing a revolutionary shift with the increasing adoption of advanced FSW Liquid Cooling Plate systems. As high-performance computing, electric vehicles, and large-scale energy storage solutions demand more efficient heat dissipation, traditional cooling methods are proving inadequate.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?