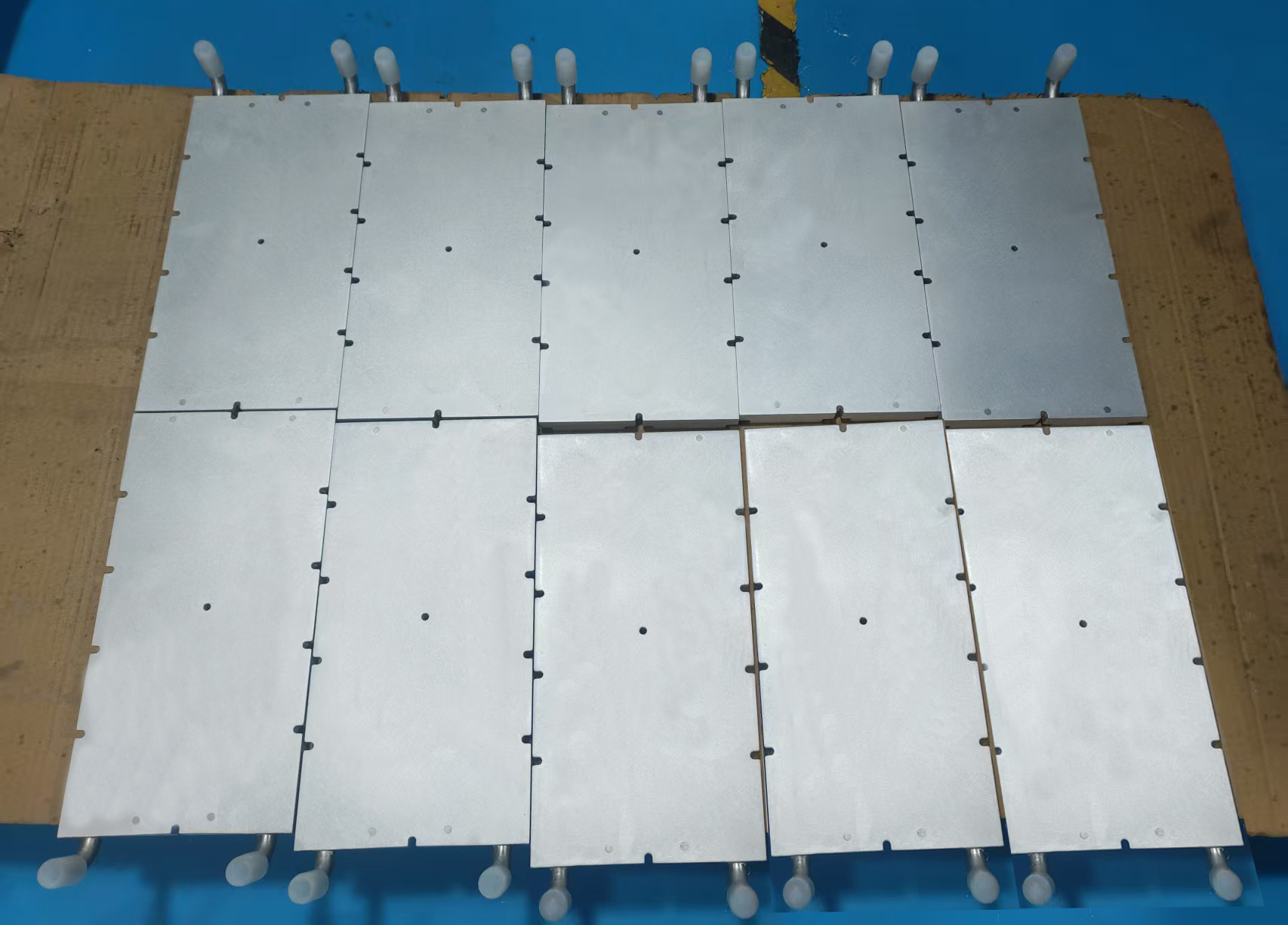

High-Precision Temperature Control Chiller Liquid Cooling Plate for Photoresist Production

A liquid cooling plate of a high-precision temperature-controlled chiller used in photoresist production, which adopts a casting process and a stainless steel pipe flow channel, completely and evenly places the flow channel in the middle, so that the flow channel does not deviate from any side of the bottom plate, and the temperature control can reach ±0.5°C.

|  |

This water-cooled plate has several major features and manufacturing process difficulties in application:

First, stainless steel pipes are used as flow channels instead of copper pipes; because the corrosion resistance requirements of water coolers are more stringent in the production of photoresists, stainless steel pipes are considered a better choice;

However, compared with copper pipes, stainless steel pipes increase the difficulty of bending. Within a limited width (132mm wide), a stainless steel pipe with a diameter of 12mm is bent 5 times, which completely exceeds the bending limit. Therefore, we adopted the method of placing it at an angle after bending to achieve the possibility of bending the pipe.

The second manufacturing difficulty is how to keep the stainless steel in the middle of the cold plate during the casting process so that it does not float or lean to any side.

The method we use is to make a fixture to fix the stainless steel, place the steel pipe in the fixture, add stainless steel columns at the bends of the stainless steel pipe, and weld the bends of the steel pipe together, so that all parts of the steel pipe are in the same plane when placed in the casting mold.

The third feature is that the steel pipe flow channel of the water-cooled plate is placed in the middle of the cold plate. Different from the conventional embedded tube process for cold plate , we use a casting process to place the stainless steel tube in the middle of the casting mold, and the cold plate is formed after the aluminum water is cooled. Placing the flow channel in the middle can make the temperature control effect of the cold plate better and more uniform.

If you are looking for a liquid cold plate manufacturer, we are willing to challenge the technical difficulty and make continuous efforts to design and manufacture your liquid cooling plate.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?