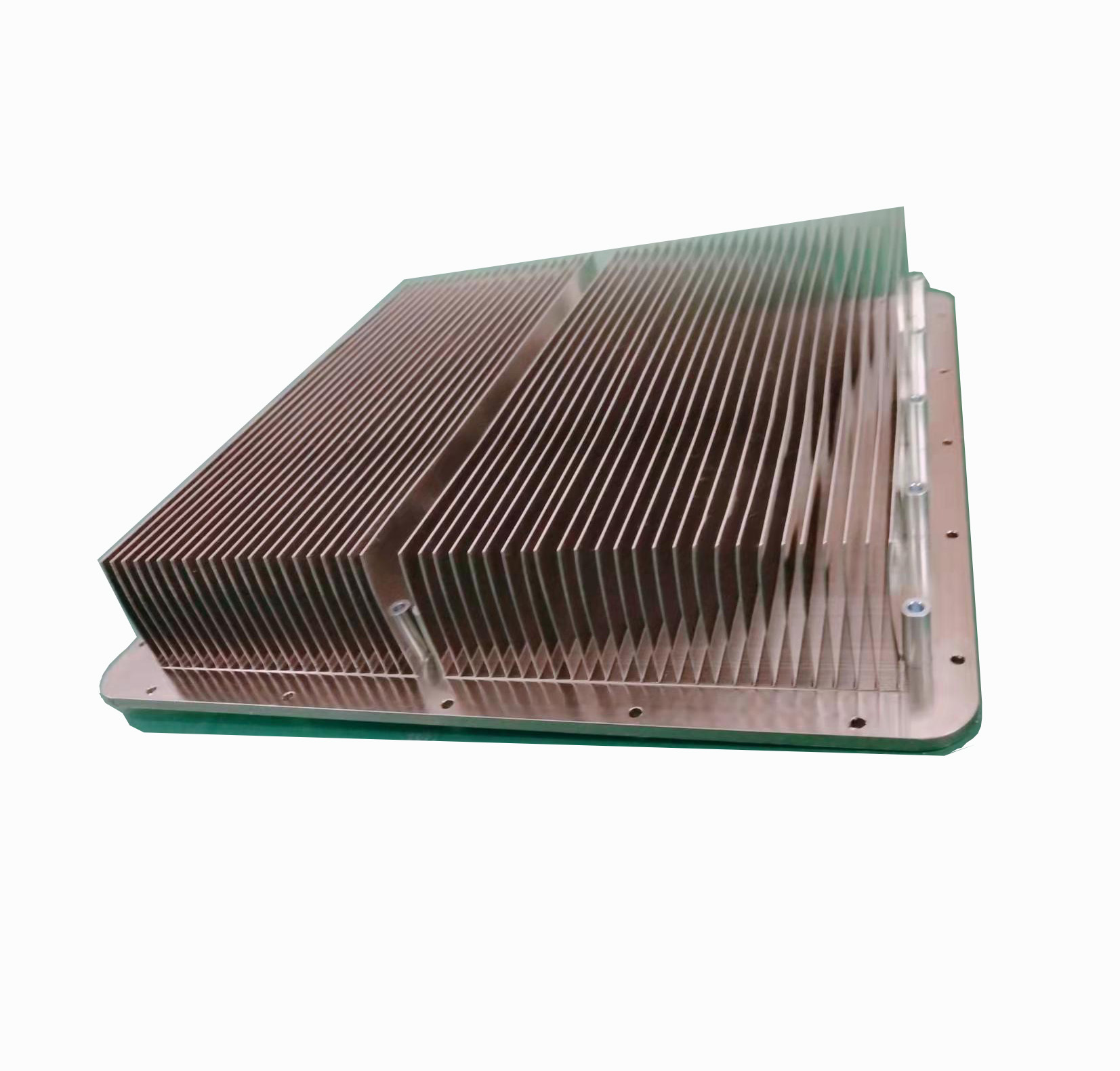

quality skived fin heat sink

Introduction to Skived Fin Heat Sink

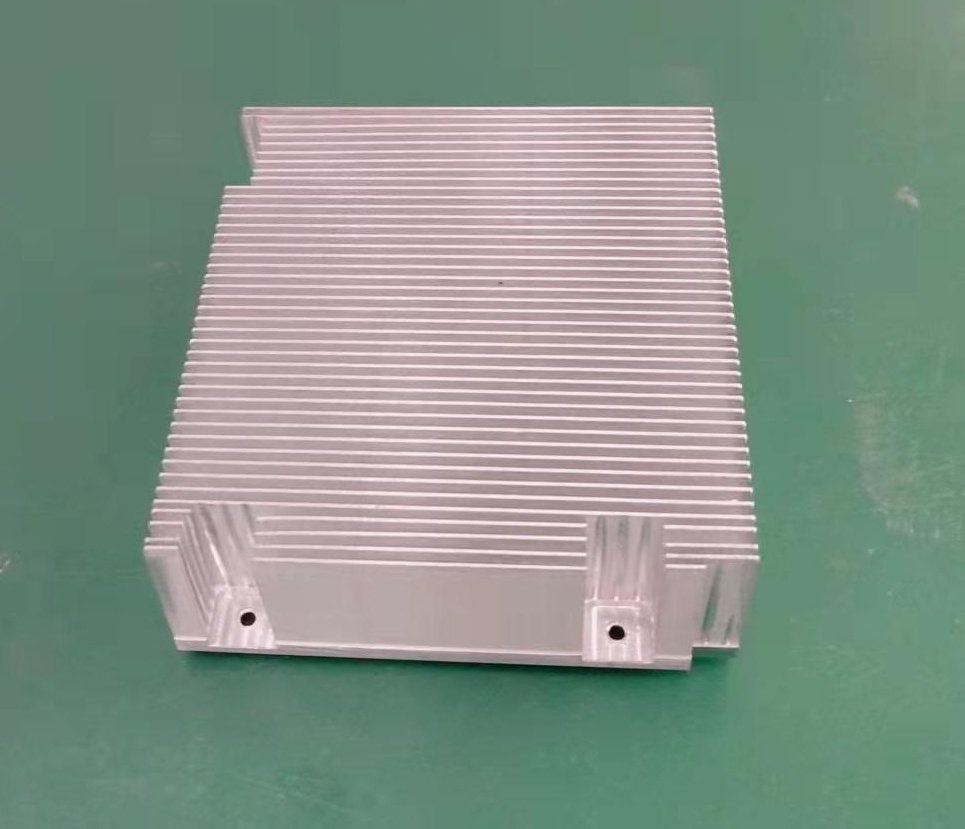

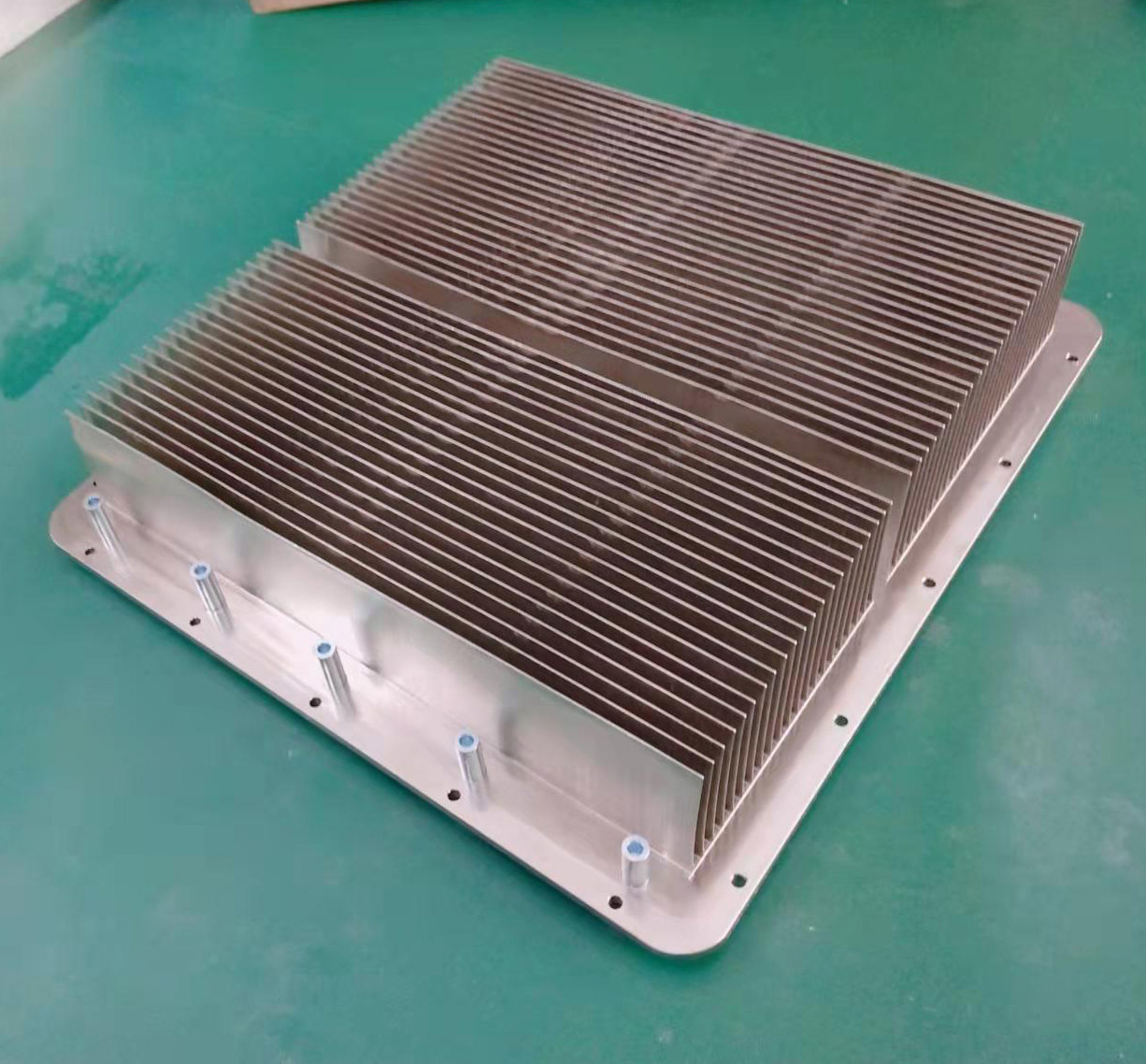

A Skived Fin Heat Sink is one of the most advanced cooling solutions used in modern electronic and industrial systems. Manufactured through a precision skiving process, this heat sink is created by shaving thin layers of material from a metal block to form high-density fins. This unique manufacturing technique allows for excellent thermal conductivity and increased surface area, which ensures efficient heat dissipation. The Skived Fin Heat Sink has become an ideal choice for industries where compact design, lightweight construction, and superior cooling performance are essential.

Advantages of Skived Fin Technology

Compared with traditional extrusion or bonded fin methods, the Skived Fin Heat Sink offers higher fin density and closer spacing, providing more effective contact with air and maximizing heat transfer. The absence of soldering or adhesive bonding improves structural integrity and eliminates additional thermal resistance. This results in better reliability and long service life, especially for devices that require continuous operation under demanding conditions. Furthermore, the ability to manufacture both aluminum and copper skived fins gives engineers flexibility in balancing cost, weight, and performance.

Applications of Skived Fin Heat Sink

The Skived Fin Heat Sink is widely applied in sectors such as telecommunications, renewable energy, automotive electronics, LED lighting systems, and aerospace equipment. For example, in high-power inverters and power supplies, it provides stable thermal control to prevent overheating and extend component life. In LED lighting, it ensures that light output remains stable while maintaining energy efficiency. The adaptability of the Skived Fin Heat Sink to both natural and forced air convection cooling makes it suitable for a broad range of environments, from compact consumer electronics to large industrial machinery.

Why Choose a Skived Fin Heat Sink

Choosing a Skived Fin Heat Sink means investing in a solution that combines excellent thermal performance, durability, and design flexibility. Its lightweight yet robust structure enhances cooling efficiency without increasing the overall size of equipment. The precise skiving process also allows for customization in fin height, thickness, and spacing, enabling tailored solutions for different thermal requirements. For businesses aiming to optimize system performance, reduce downtime, and extend product lifespan, the Skived Fin Heat Sink is a highly reliable and cost-effective option.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?