Inverter Skived Heat Sink Driving Efficiency in Power Electronics

In today’s rapidly advancing electronics industry, efficient thermal management solutions have become the backbone of reliable performance. One of the most significant developments gaining attention is the inverter skived heat sink, a cutting-edge innovation designed to address the growing demand for compact, durable, and highly effective cooling systems. As power inverters are widely adopted across renewable energy, automotive, and industrial applications, the need for robust cooling technology is more critical than ever. The rise of the inverter skived heat sink highlights a new chapter in the balance between miniaturization, energy efficiency, and system reliability.

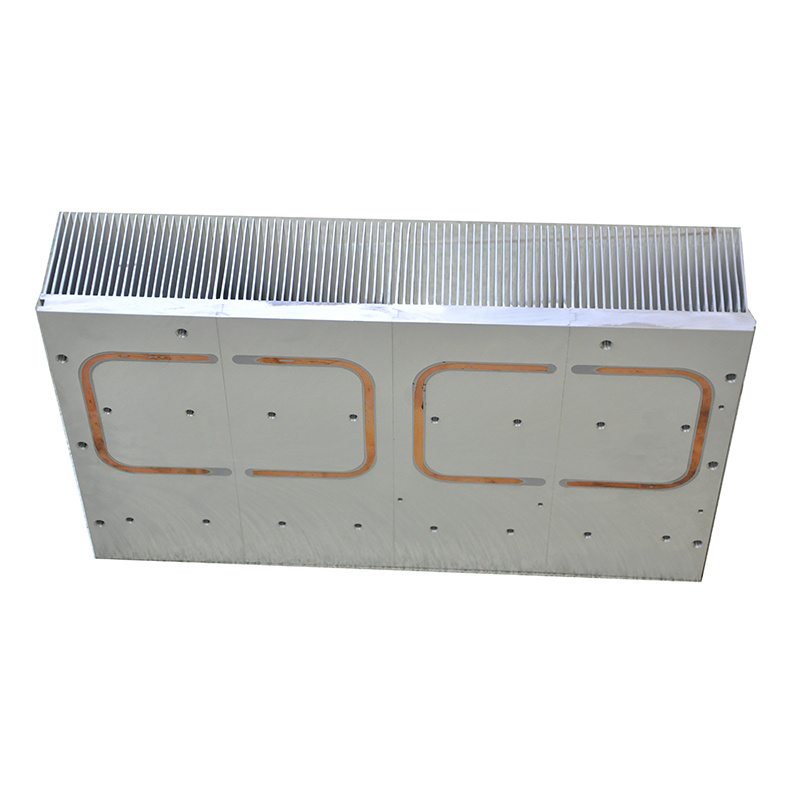

Unlike traditional extruded or bonded heat sinks, the inverter skived heat sink is manufactured through a precision skiving process that enables the creation of ultra-thin, densely packed fins. This design dramatically increases the surface area for heat dissipation while maintaining structural strength. Engineers emphasize that this innovation not only enhances cooling capacity but also reduces weight and volume, making it particularly suitable for modern inverter systems where space is limited. With global industries pushing towards higher power density and sustainability, this new heat sink technology is setting higher standards in the market.

Industry experts point out that renewable energy systems, such as solar inverters and wind power converters, benefit significantly from this advancement. The inverter skived heat sink allows devices to operate at lower temperatures, ensuring greater efficiency and extending the lifespan of sensitive electronic components. Similarly, in electric vehicles, where inverters play a central role in power conversion, improved thermal management is essential to achieve consistent performance and safety. By integrating skived fin technology, manufacturers are not only achieving better heat transfer but also enhancing the competitiveness of their products in the global marketplace.

Market analysts predict that the adoption of the inverter skived heat sink will accelerate in the coming years, as industries increasingly seek eco-friendly and high-performance thermal solutions. With applications expanding across data centers, 5G telecommunications, and smart grid infrastructures, the demand for reliable inverter cooling is set to soar. This innovative product is not just a technological improvement—it represents a strategic shift toward sustainability, energy conservation, and operational excellence. As the world moves toward a greener and more electrified future, the inverter skived heat sink stands out as a cornerstone of progress in thermal engineering.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?