The Rising Dominance of IGBT Liquid Cold Plates in High-Power Electronics

The relentless push for higher power density and efficiency in electronics is driving a thermal management revolution. At the heart of this transformation is the IGBT Liquid Cold Plate, a sophisticated cooling solution rapidly becoming indispensable in industries ranging from electric vehicles (EVs) to renewable energy and industrial automation.

Insulated Gate Bipolar Transistors (IGBTs) are the workhorses of high-power applications, acting as efficient switches controlling large amounts of electrical energy. However, their operation generates significant waste heat. Managing this heat is paramount; excessive temperatures degrade performance, reduce lifespan, and can lead to catastrophic system failure. Traditional air cooling methods are increasingly inadequate for next-generation, high-power-density modules. This is where liquid cooling, specifically through an IGBT Liquid Cold Plate, provides a superior alternative.

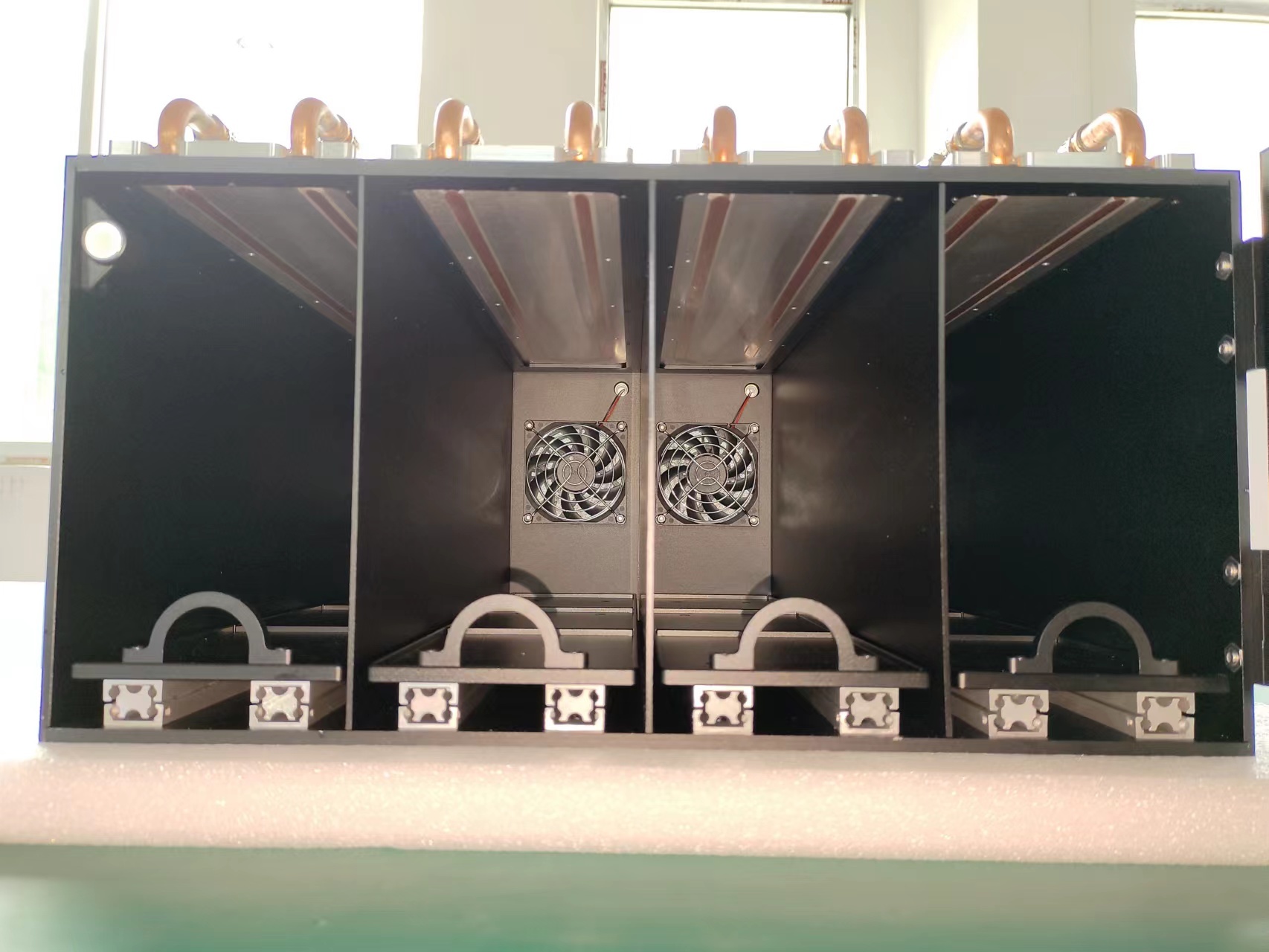

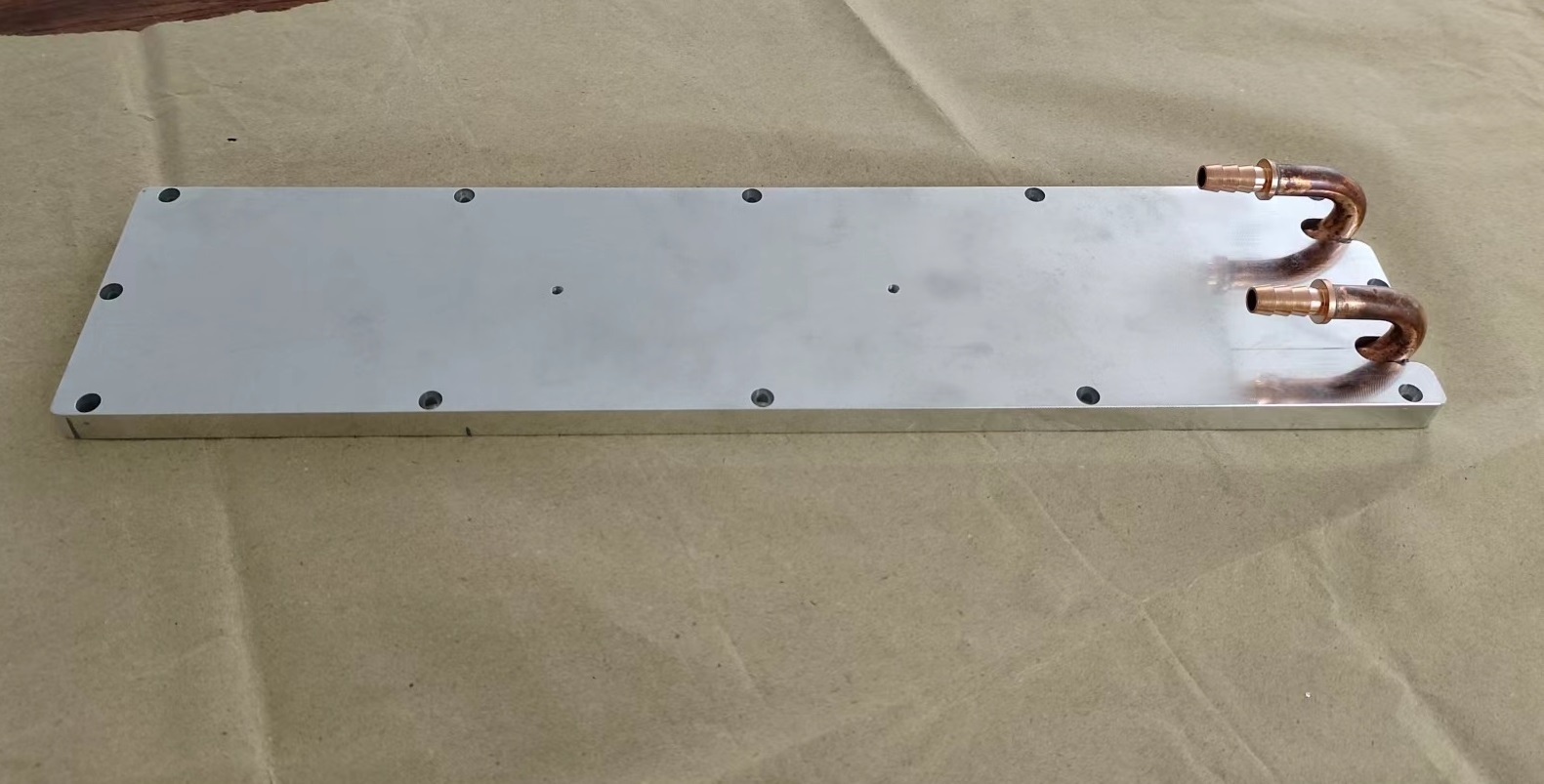

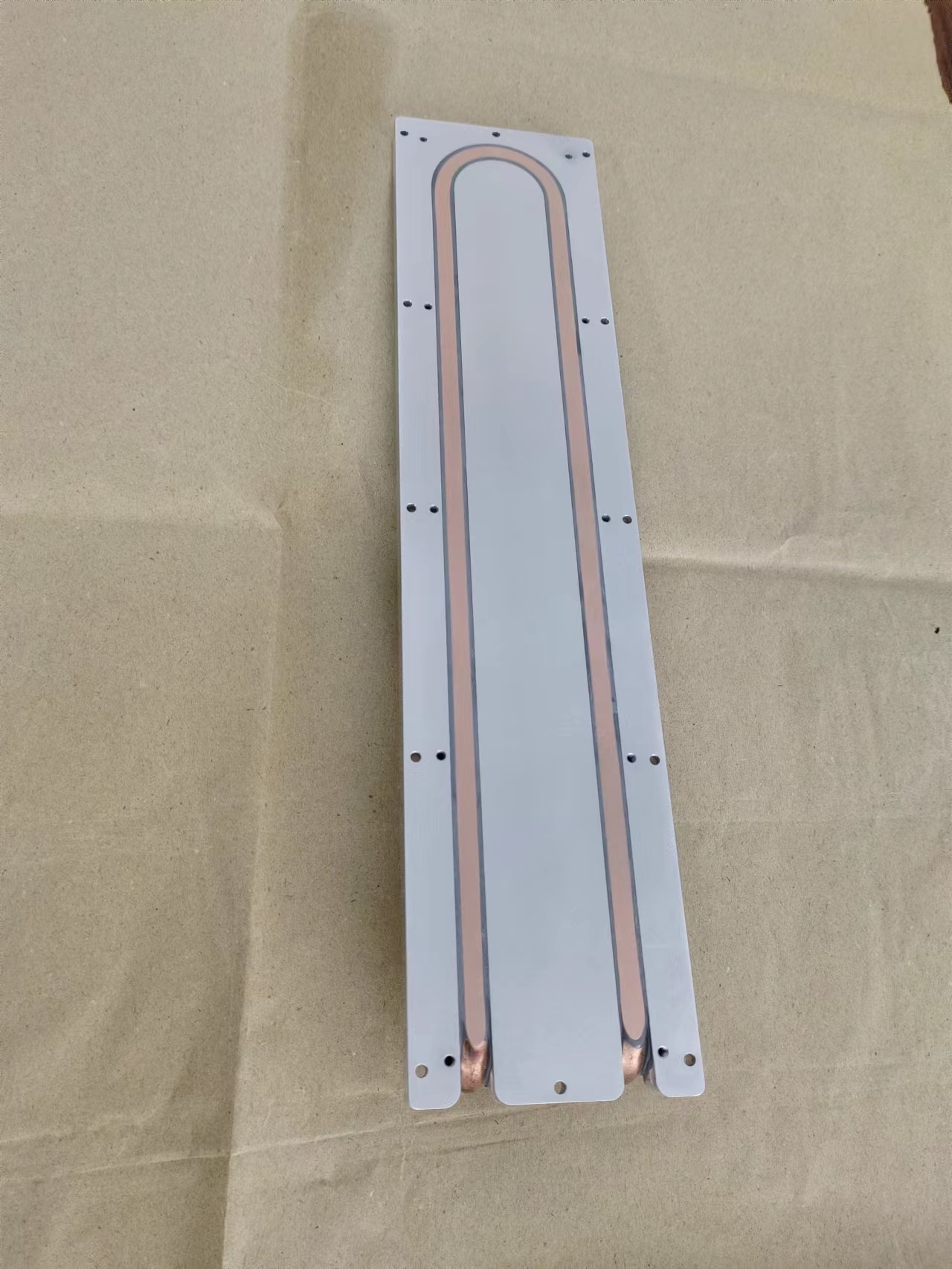

An IGBT Liquid Cold Plate is a custom-designed metal component, typically made from aluminum or copper, that is mounted directly onto the IGBT module. Its internal structure features a complex network of micro-channels through which a coolant fluid – often a water-glycol mixture – is circulated. Heat is transferred from the semiconductor directly into the cold plate and then efficiently carried away by the moving liquid. This method offers a dramatically higher heat transfer coefficient compared to air, allowing for more compact designs and higher operational power levels.

As power levels continue to climb and the demand for miniaturization persists, the role of the IGBT Liquid Cold Plate will only grow more critical. It is no longer just a ancillary component but a fundamental enabler of progress in high-power electronics, ensuring that the systems powering our modern world remain efficient, reliable, and cool under pressure.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?