Vansim (Dongguan)Hardware Products Co., Ltd.

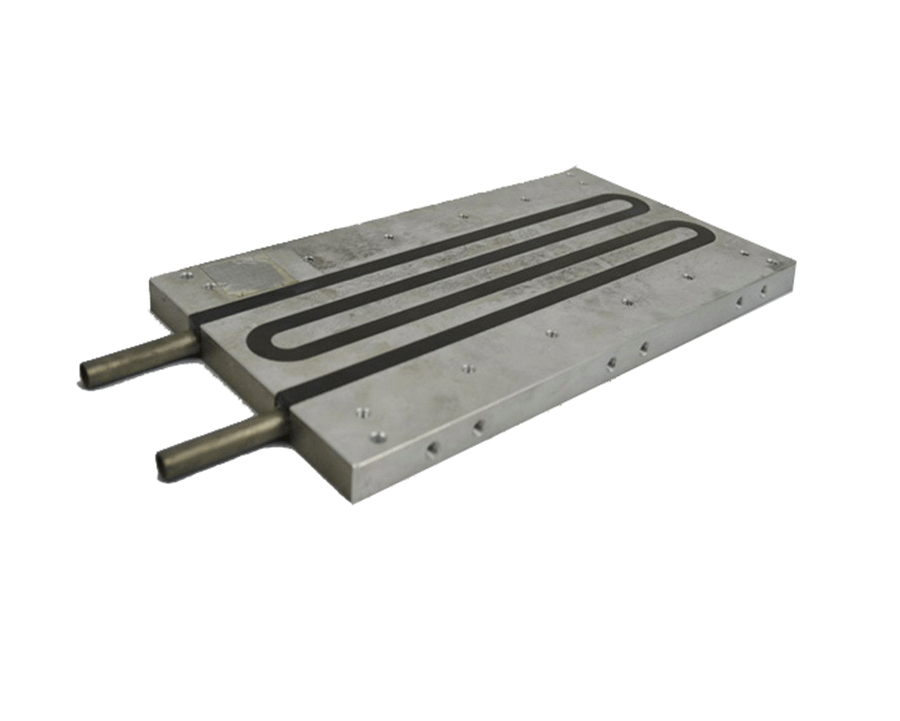

Deep Drilling Cold Plate

The simple straight channel makes cold plate processing convenient.

Which is the choice for your design with small demand and cost advantage.

Deep Drilling Cold Plate

Process introduction:

Several direct current channels are processed on the aluminum substrate by deep hole drilling technology, and the side drilling or end surface machining methods are used to connect the direct current channels to form a complete flow channel. Except for the inlet and outlet, other openings can be sealed by friction stir welding, argon arc welding, laser welding, etc., and then processed into a liquid cooling plate after mechanical processing and surface treatment.

Design Reference:

Common tool diameters for deep hole drilling of liquid cooling plates:

Φ5mm, Φ6mm, Φ7mm, Φ8mm, Φ9mm, Φ10mm, Φ11mm, Φ12mm, Φ13mm, Φ14mm, Φ15mm, Φ16mm, Φ17mm, Φ18mm, Φ20mm

Deep hole drilling channel depth can be up to 1600mm

Application Status:

The deep hole drilling liquid cooling plate has a simple flow channel structure that is easy to process, has good product stability, can be installed on both sides of the liquid cooling plate for heat dissipation, and has a large flow channel depth, which is very suitable for making long flow channel liquid cooling plates; at the same time, due to the processing characteristics, the flow channel is a simple straight structure, and the design flexibility is relatively low.

It is particularly important to improve the radiator cutting and processing efficiency and shorten the production cycle.

Deep drilling process can meet the shorten production delivery very well,It is easy and convenient for operating.

FSW machining the insert block for the deep drilling cold plate.

Deep drilling the straight channels + insert block , After FSW process and CNC machining, To be a cold plate!

Or use laser welding plugging method, laser welding has the characteristics of high processing efficiency, smooth weld, low welding follow-up workload, stable penetration, and can achieve precision welding. How about the firmness and airtightness of laser welding? After the workpiece is welded, airtightness test and pressure resistance test are carried out. Generally, there is no problem in withstanding pressure of about 2Mpa.

More varieties Copper tube liquid cold plates :

// CONTACT US

Didn'T Find The Service You Want?

For inquiries about our products, please email to us and we will be in touch within 24 hours.

We Support Customization

Continue To Create Greater Value For Customers

Contact Us

No. 10, Minying West Road, Hengli Town, Dongguan City, China 523390

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.