FSW Liquid Cooling Plate Technology Driving Next-Generation Thermal Management

Innovation in Cooling Solutions

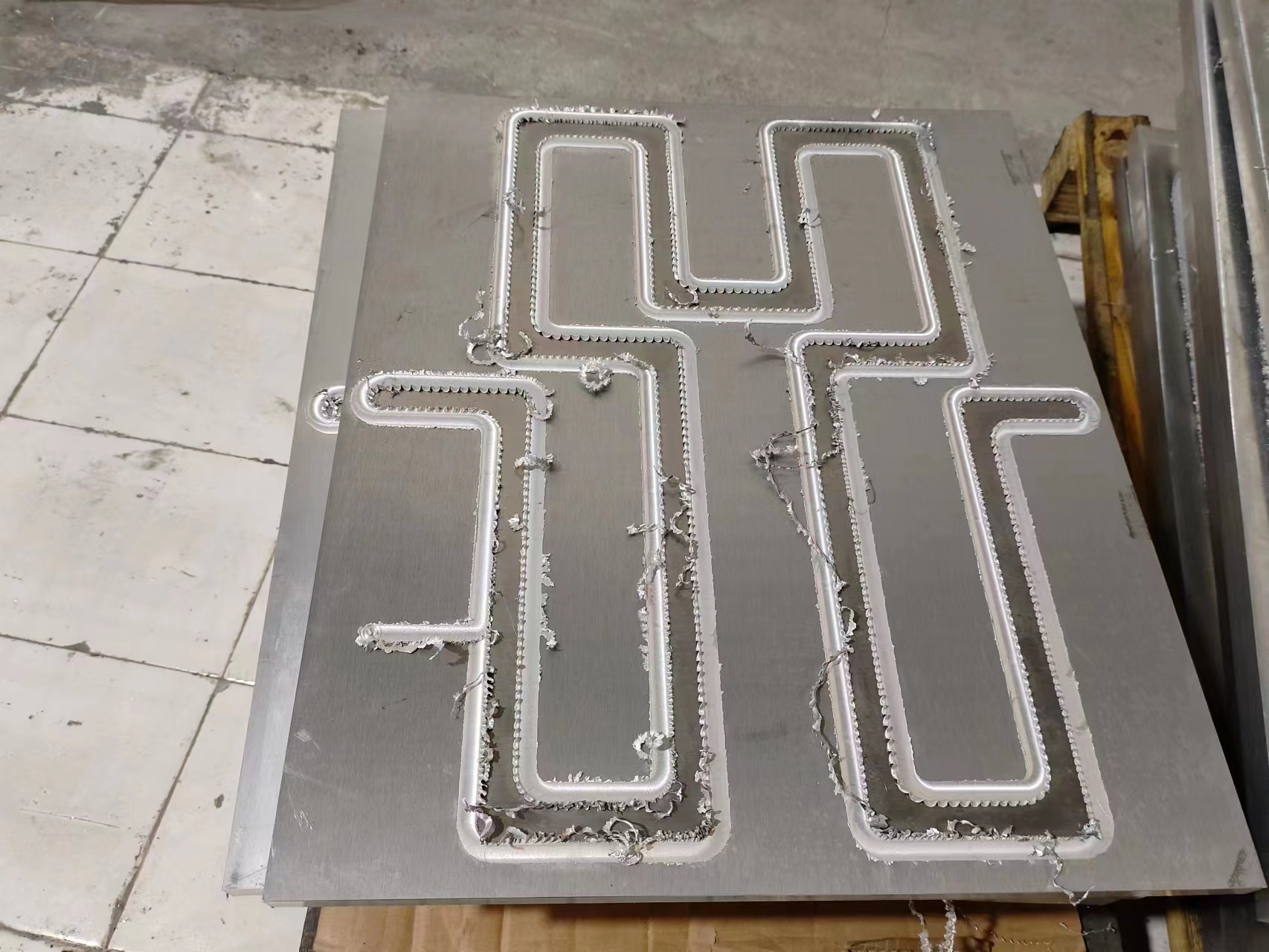

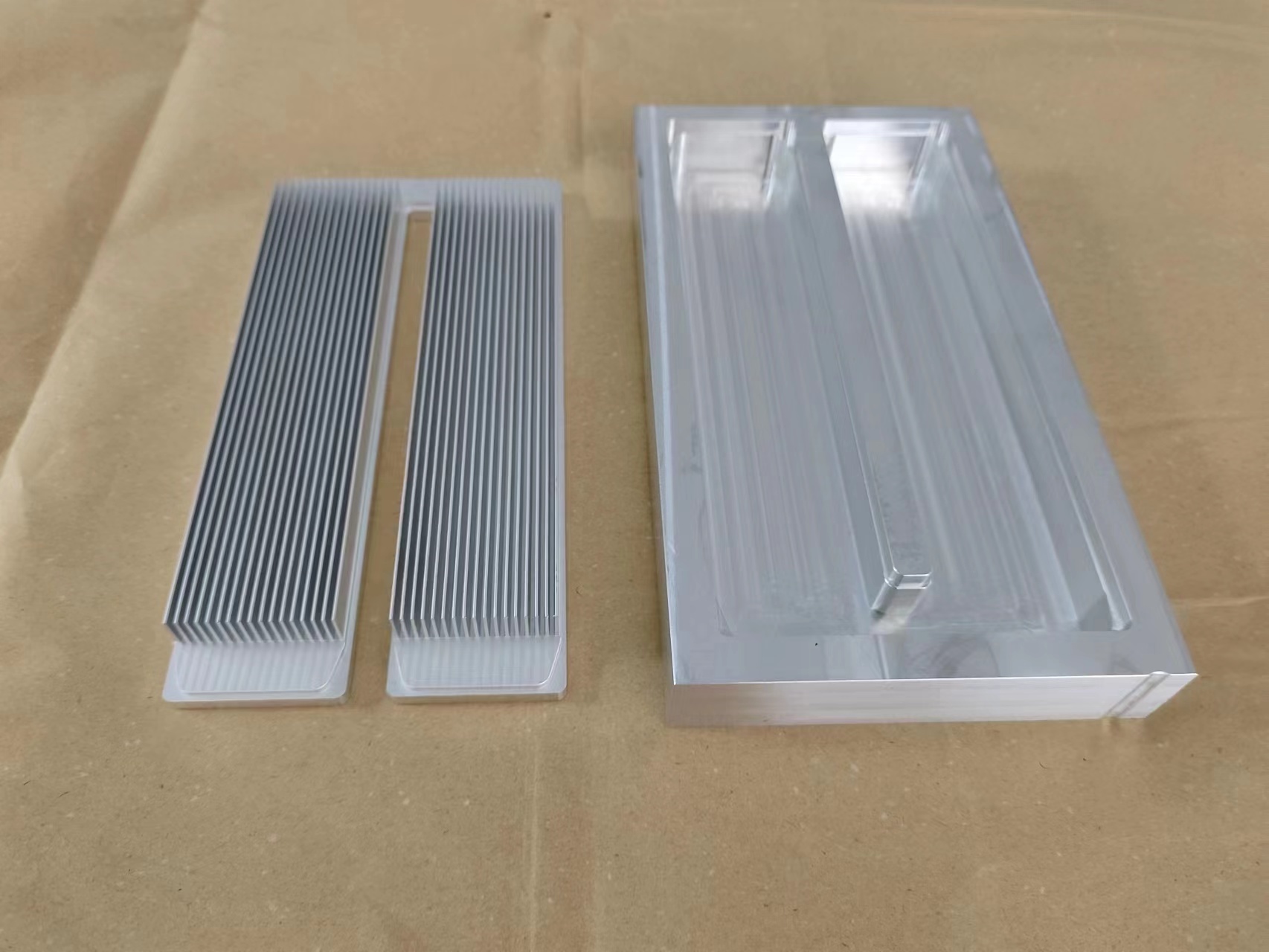

The rapid advancement of electronics and electric vehicles has created a growing demand for efficient thermal management systems. Among the most promising solutions, the FSW Liquid Cooling Plate has emerged as a game-changer. Using friction stir welding (FSW) technology, these plates provide exceptional heat dissipation performance, ensuring that high-power components remain within optimal temperature ranges.

Advantages of FSW Integration

Unlike traditional brazed or gasket-sealed plates, the FSW Liquid Cooling Plate offers superior structural integrity and leak-proof reliability. The solid-state welding process eliminates porosity and ensures a high-quality bond, which is particularly important in battery packs, inverters, and power modules. Manufacturers are rapidly adopting this technology to meet the increasing power density of modern devices.

Growing Industrial Adoption

Automotive, data center, and renewable energy sectors are showing strong interest in the FSW Liquid Cooling Plate. Electric vehicle makers use them to regulate battery temperature, enhancing driving range and safety. Data centers deploy them to maintain consistent thermal performance in high-density servers, reducing energy consumption and improving uptime.

Future Outlook and Market Trends

Industry analysts predict significant growth for FSW Liquid Cooling Plate solutions over the next decade. Continuous innovation in design, lightweight materials, and manufacturing processes will likely expand their applications. As the demand for high-efficiency cooling continues to rise, this technology is poised to become the standard for next-generation thermal management systems.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?