Friction stir welding (FSW) process is used for liquid cooling plates in battery cooling systems

The advantages of the friction stir welding liquid cold plates are that the flow channel can be flexibly designed according to requirements, no need to fill welding wire and inert gas protection, environmentally friendly production and other characteristics.

Vansim's most commonly used friction stir welding liquid cooling plate processing procedures:

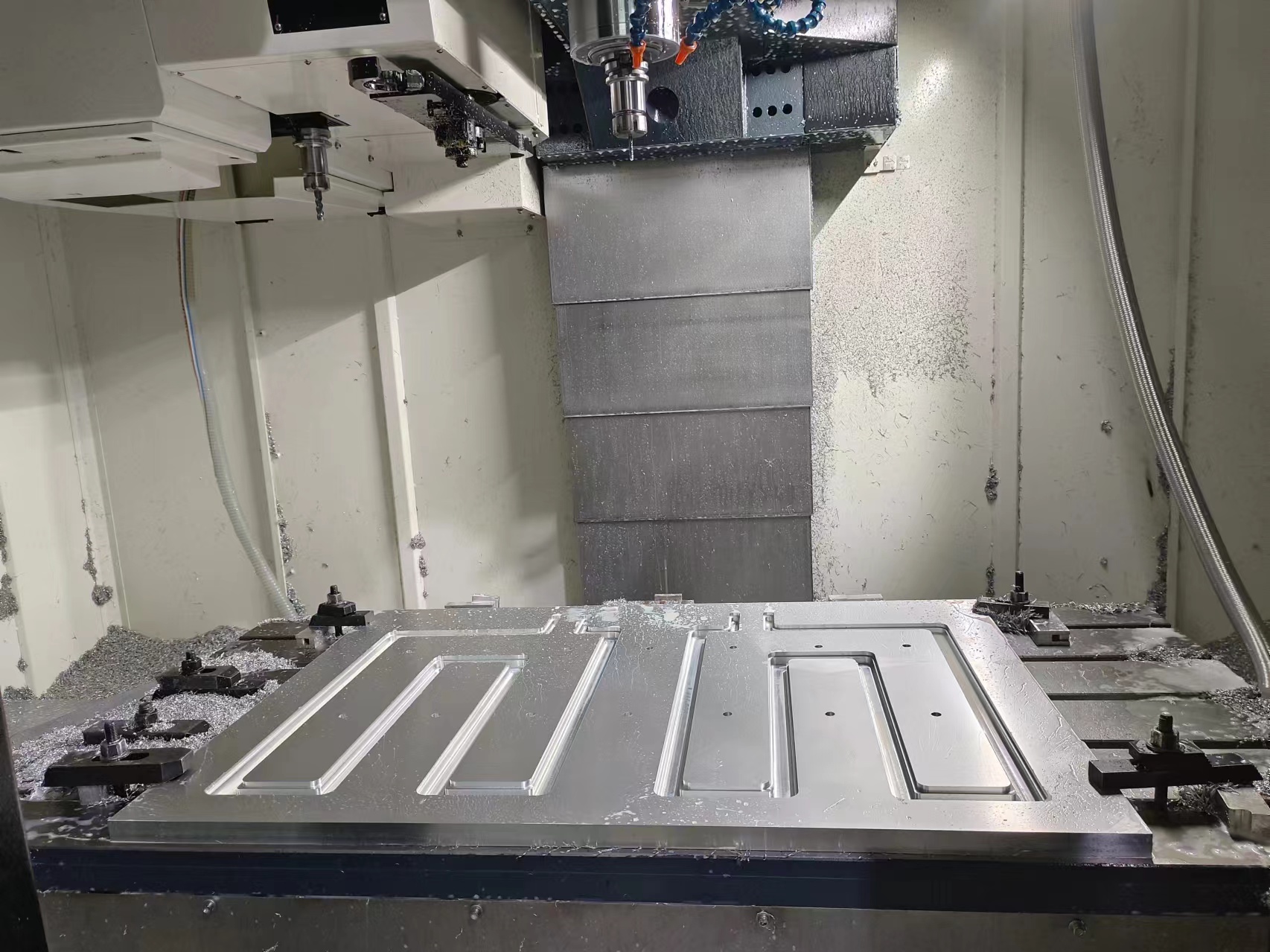

1. According to the process requirements of the finished product structure and welding technology, CNC processes the flow channel bottom plate and cover plate;

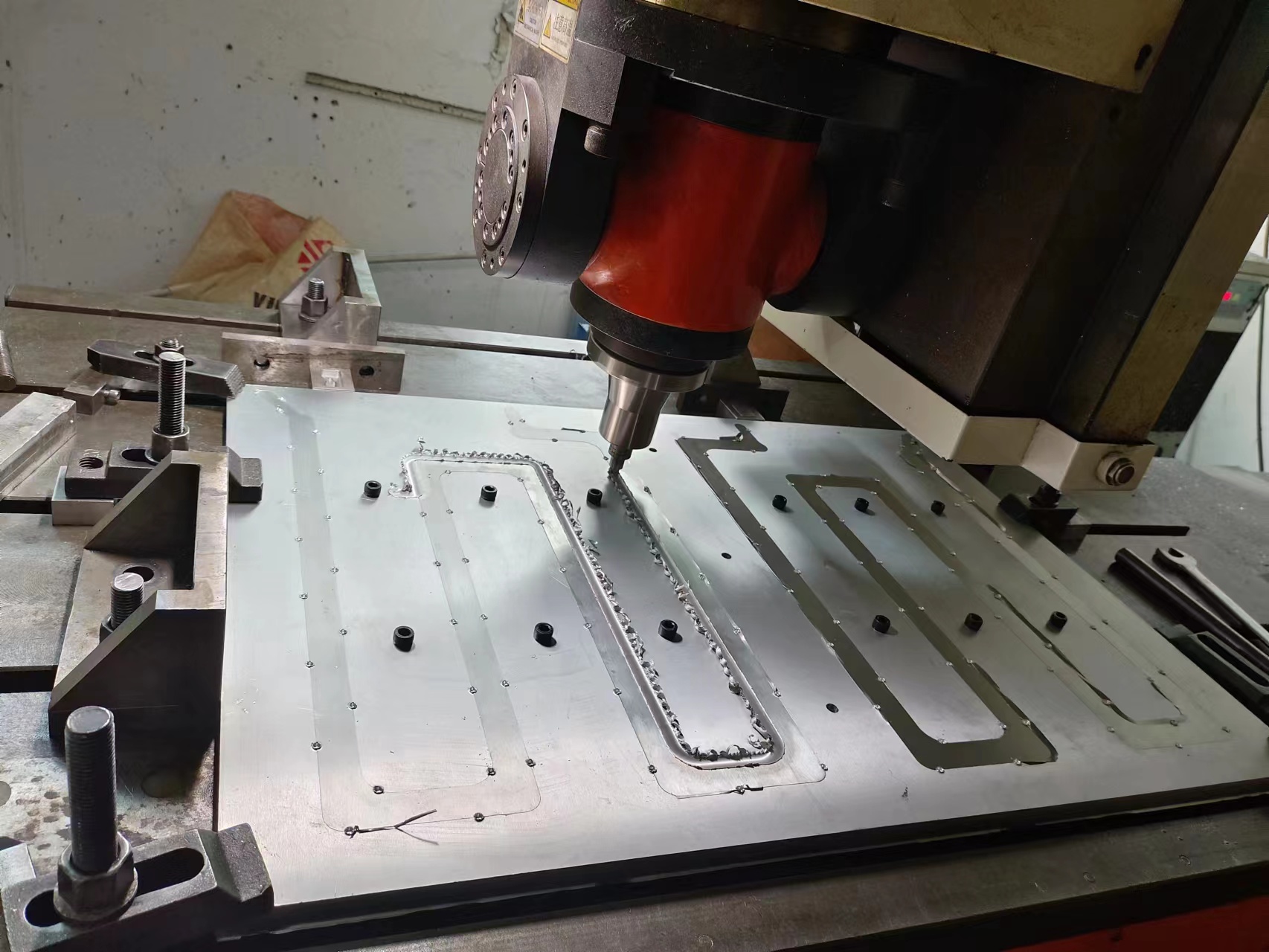

2. Install it on the friction stir welding equipment, first spot weld the workpiece to be welded, then stir friction weld along the weld, and complete the welding of the entire weld.

3. Check the strength and sealing of the weld. After the inspection is OK, the weld surface is processed again by CNC.

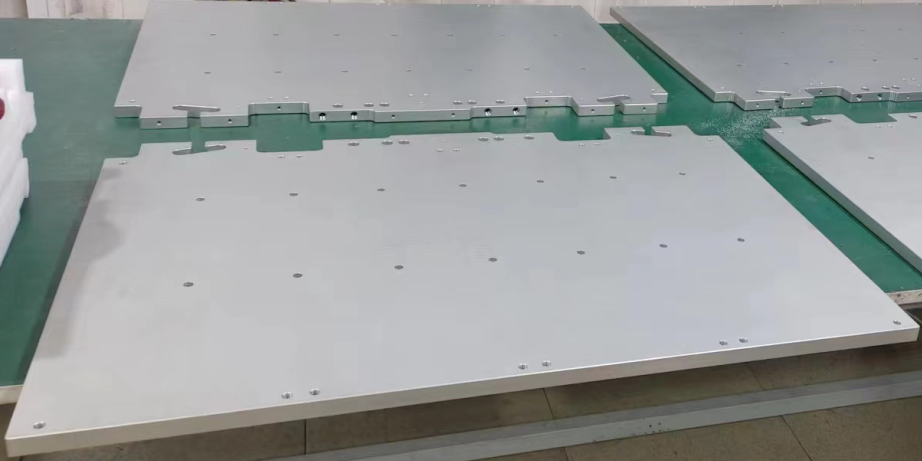

4. The finished product is processed by CNC, and then the finished water cooling plate with smooth surface and perfect weld can be obtained.

In the process of friction welding water cooling plate, the deformation of the water cooling plate caused by friction welding makes the subsequent CNC finished product processing more difficult. Usually, the calibration process is used to meet the CNC processing requirements and then complete the finished product process.

With the continuous growth of energy demand, the demand for battery water cooling plates in the market is also increasing. Battery water cooling plate is a device that realizes battery thermal management through water circulation, and is mainly used in new energy vehicles and energy storage systems. The heat generated by the battery during operation is transmitted through the contact between the electronic components and the surface of the plate-shaped aluminum device, and is finally taken away by the coolant in the flow channel inside the device plate. This plate-shaped aluminum device is the water cooling plate.

Friction welding liquid cooling plate is the most commonly used welding process water-cooled plate in Vansim's battery water-cooled plate. Vansim's friction welding technology can reasonably select welding tools, properly design welding tool paths, and have good matching of welding fixtures. It can completely avoid common defects in fusion welding such as cracks, pores and incomplete penetration, and obtain uniform and consistent welding quality, which can control the welding quality of the water-cooled plate during the welding process.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?