Battery Cooling System

There are many battery application fields. Vansim can provide you with the heat dissipation solutions in the application fields we are good at. Please contact us for details!

Batteries are an important energy source. In what fields are they commonly used?

1. Transportation fields such as electric vehicles, hybrid vehicles, and light rail trains all require batteries to provide power.

2. In the field of power storage, batteries can be used as a power storage device to store excess power for emergency use.

3. Applications in the aerospace field, such as satellites, rockets, and airplanes, all require batteries to provide energy.

4. Military fields such as unmanned reconnaissance aircraft and unmanned vehicles all require batteries to provide energy.

5. Communications fields such as mobile phones, tablets, and routers.

In the field of new energy storage, thermal management systems are gradually becoming an indispensable part of ensuring the safe and efficient operation of battery energy storage systems. With the large-scale application of renewable energy such as wind power and photovoltaics, the stability and safety issues of energy storage systems have become increasingly prominent, and thermal management systems play a vital role in this challenge. The main functions of energy storage thermal management systems are: battery heat dissipation, battery preheating, temperature balance, energy storage and scheduling, and thermal energy recycling.

What is a battery thermal management system?

A battery thermal management system regulates the battery's temperature conditions to keep the battery operating safely and efficiently. High battery temperatures accelerate battery aging and pose safety risks, while low temperatures can lead to reduced battery capacity and reduced charge/discharge performance.

A battery thermal management system controls the battery's operating temperature by dissipating heat when the battery is too hot or providing heat when it is too cold. Active, passive, or hybrid heat transfer solutions are typically used to regulate the battery temperature in these systems.

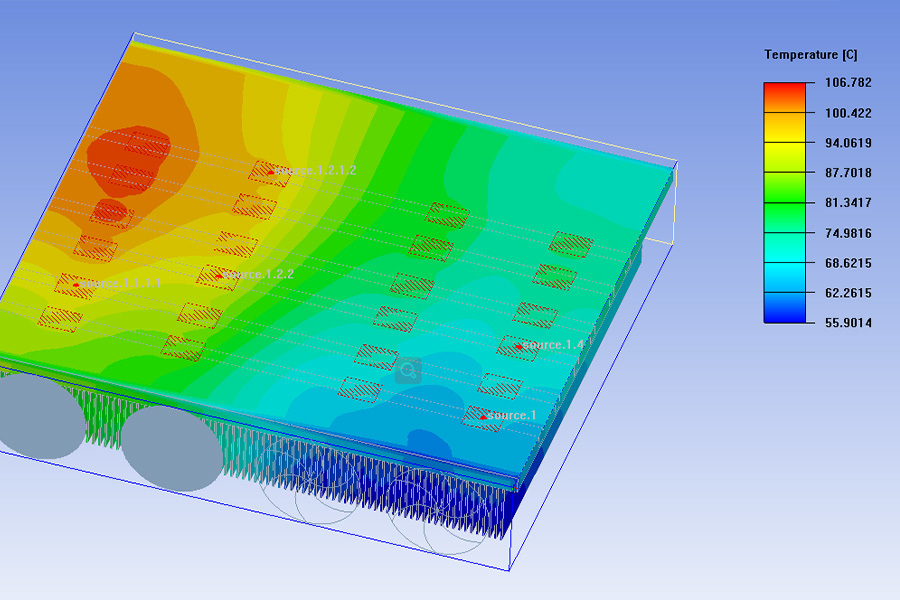

The thermal conductivity and specific heat capacity of liquid are higher than those of air, so the heat exchange efficiency of liquid cooling system is higher, which can better meet the heat dissipation requirements under high current, high power or complex working conditions.

The coolant circulates in the internal flow channel, absorbs heat and releases it to the environment through the radiator. When designing the system, factors such as the selection of coolant, pipeline layout, pump selection and control system design need to be considered to ensure stable operation and efficient heat dissipation of the system.

With the continuous development of new energy storage technology and the growing demand for its application, thermal management technology will face more challenges and opportunities.

The technical route of energy storage thermal management system adopts different heat dissipation technologies:

Air cooling technology: With its simple structure, safe and reliable and easy to implement characteristics, it has been widely used in container energy storage systems and communication base station energy storage systems with low power density.

Liquid cooling technology: Using coolants such as water, ethanol, silicone oil, etc., to dissipate heat through indirect contact with the battery cells through the guide grooves on the liquid cooling plate. The advantages of this technology are its efficient cooling capacity and floor space saving, which is very suitable for the needs of future large-scale energy storage power stations.

Phase change cooling technology: Cooling is carried out by using the principle that phase change materials absorb heat during the phase change process. Phase change materials have a limited service life, and they need to rely on other heat dissipation systems such as liquid cooling or air cooling to export the absorbed heat.

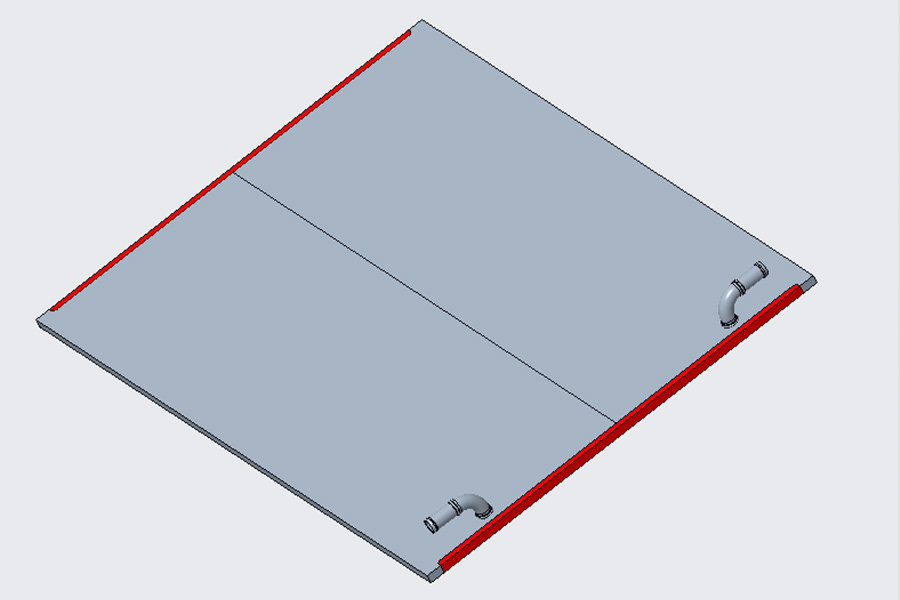

Application of liquid cooling plate in battery cooling system

The key to the heat dissipation of the battery lies in the design and laying of the coolant pipes and the direction of coolant flow. Only by reasonably forming a reflux path and achieving uniform heat dissipation can the overall heat dissipation of the power battery be maintained at a uniform temperature level, without some temperatures being too low and some temperatures being too high, thus affecting the health of the battery.

Water cooling plate technology commonly used in battery liquid cooling

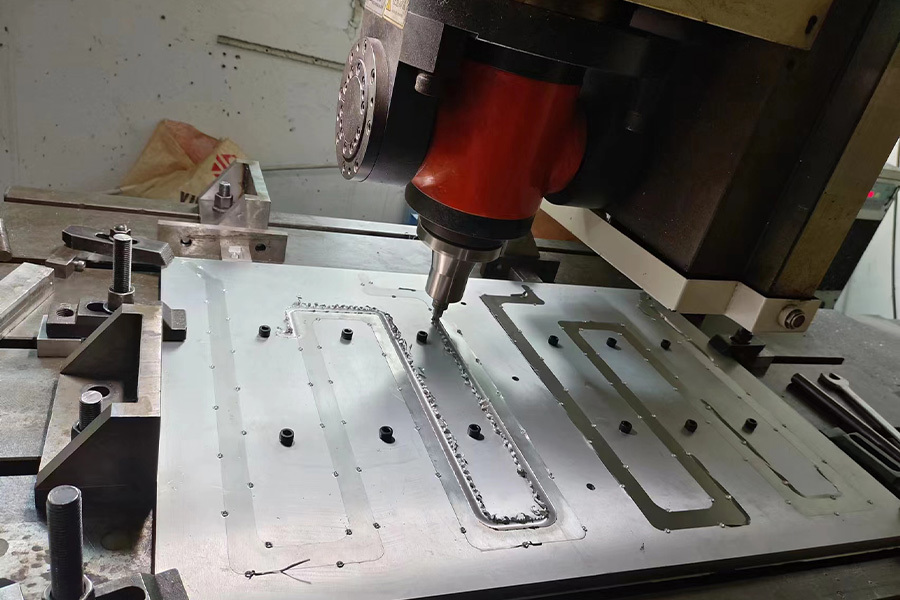

The brazed process cold plate: Use the thin stamp plate cover and base, Through brazed process and CNC machined . Thinner thickness and light weight are the advantages.

The FSW process cold plates: CNC machining channel base or extrusion channel body, Through FSW process make the fluid flow complete. Flexible design is the advantage.

Aluminum extruded direct current channel and water-cooling plates with friction welding ends are suitable for projects with larger demand.

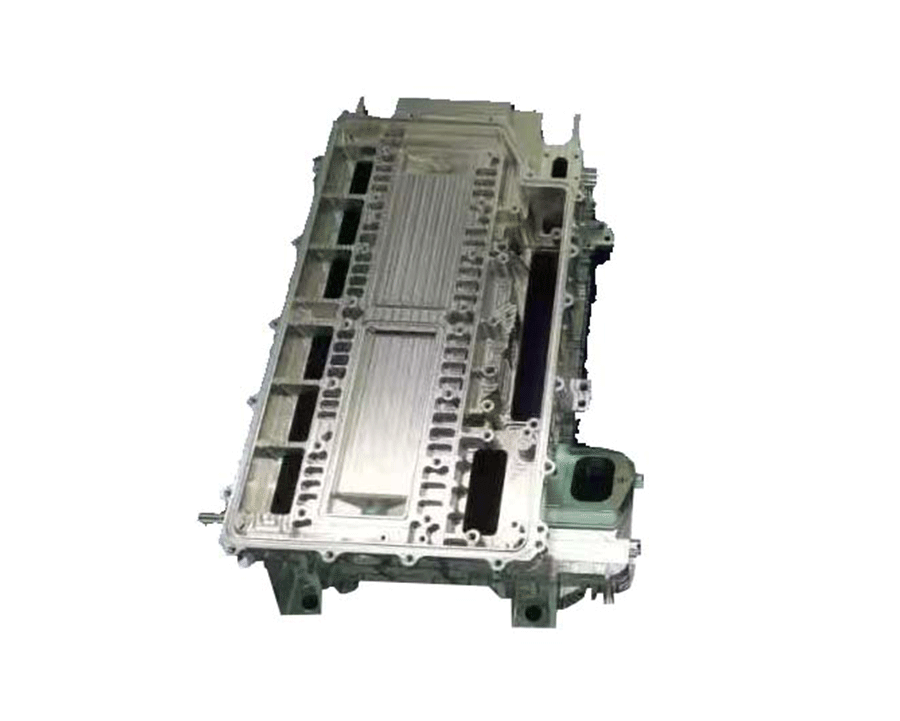

(BMS)The role of battery management system in battery application

The core functions of BMS include battery cell monitoring, state of charge (SOC) estimation and battery cell balancing. Specifically:

Battery monitoring: Collect the voltage, temperature and battery pack current of the single cell, reasonably set the position and number of temperature sensors, and ensure the working state of the battery pack.

SOC estimation: Accurately estimate the remaining power of the battery through methods such as ampere-hour integration method and open circuit voltage calibration method to improve the efficiency and service life of the battery pack.

The battery management system is one of the core components of electric vehicles, power tools and energy storage systems. In high-power and high-density battery systems, BMS generates a lot of heat. If it cannot be effectively dissipated, it may affect its performance and life, and even cause safety problems.

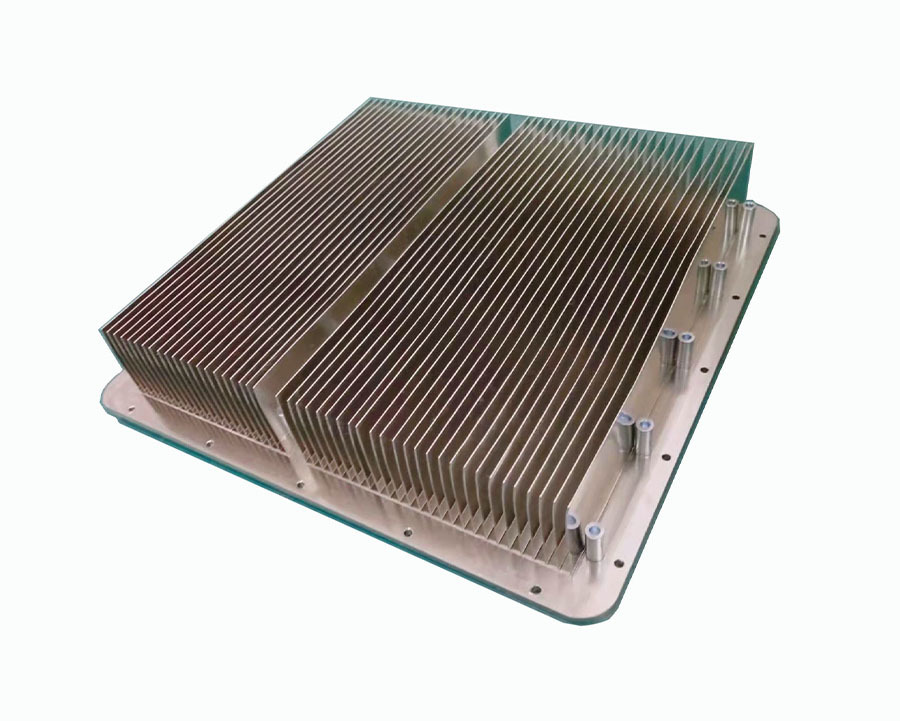

The application of heat sinks in BMS is mainly to ensure the stable operation of BMS boards and the overall performance of battery management systems by increasing the heat dissipation area, optimizing the structural design, selecting suitable thermal conductive materials and temperature monitoring management.

Common heat sink processes include skiving heat sink and aluminum extruded heat sinks.

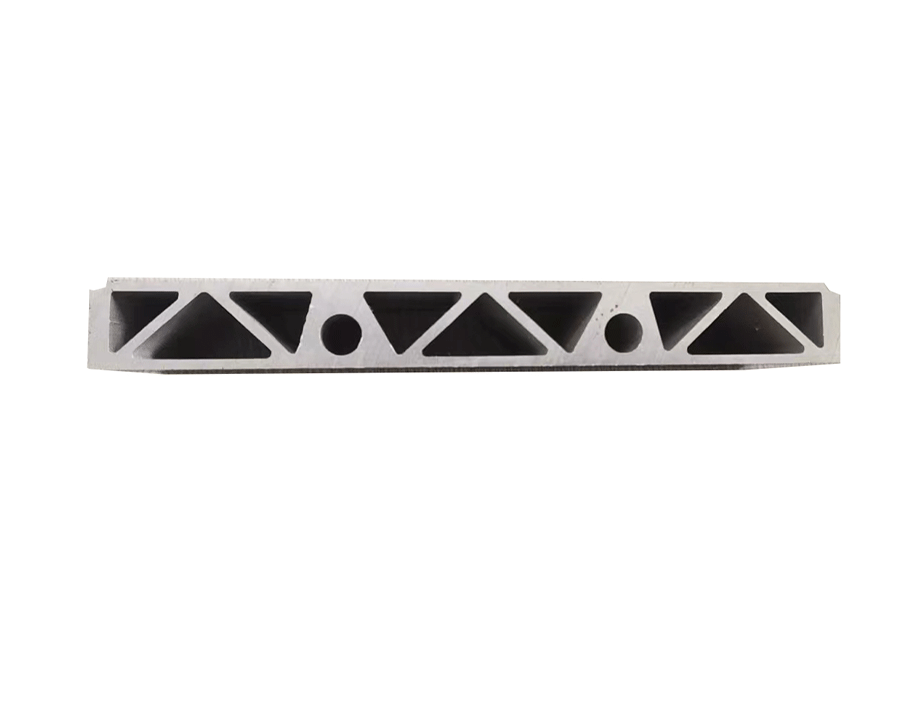

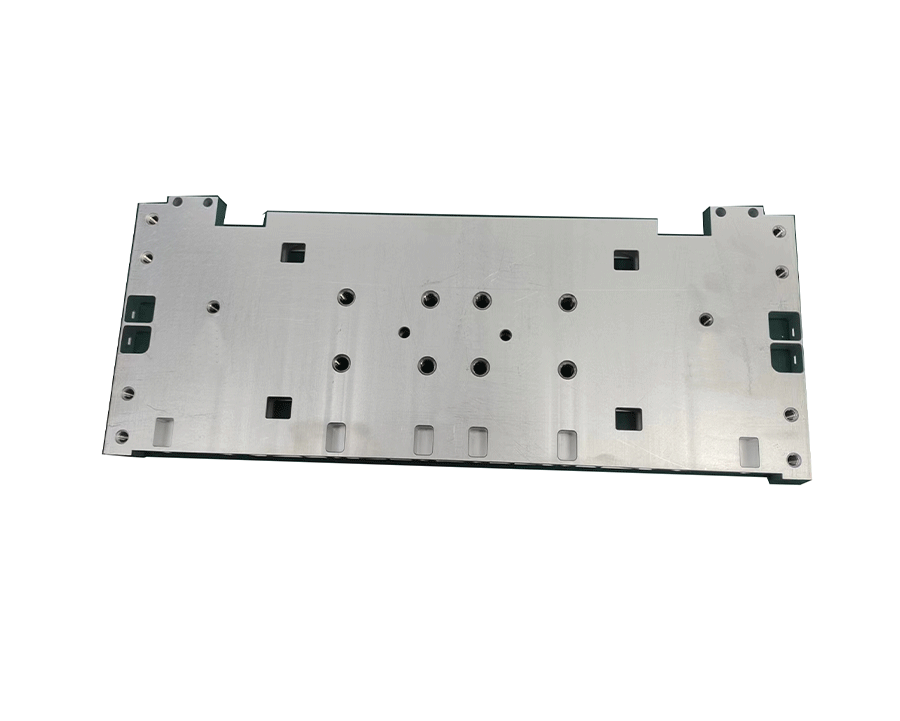

Battery module—Battery end plate

Battery end plates play an indispensable role in battery modules. Battery end plates are usually extruded through aluminum extrusion dies and then processed by CNC. The design of CNC processing jigs pursues efficient output with stable quality.

More Varieties Thermal Products: