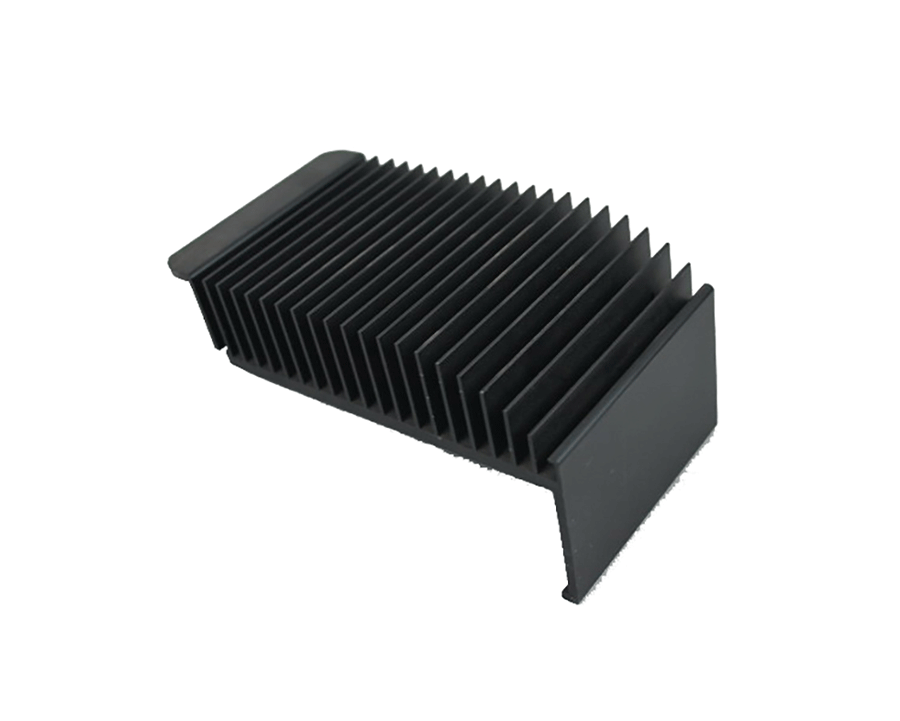

Extrusion Heat Sinks

After the aluminum rod is heated to the plastic temperature (400℃~500℃), the extruder uses oil pressure to extrude the aluminum rod through the extrusion die to become the required profile. The aluminum extrusion profile is processed into a radiator through cutting, machining, surface treatment, etc.

Extrusion Heat Sinks

Process introduction:

After the aluminum rod is heated to the plastic temperature (400℃~500℃), the extruder uses oil pressure to extrude the aluminum rod through the extrusion die to become the required profile. The aluminum extrusion profile is processed into a radiator through cutting, machining, surface treatment, etc.

Aluminum Bar

Profile Mold

Aluminum Extrusion Die

Design Parameters

The basic parameter of extrusion is as below:

|

Machine Tonnage |

Product Diagonal |

Fin Height/Fin Gap Multiples |

Machine Tonnage |

Product Diagonal |

Fin Height/Fin Gap Multiples |

|

600T |

﹤120mm |

24 |

2750T |

﹤250mm |

21 |

|

880T |

﹤130mm |

24 |

3000T |

﹤320mm |

20 |

|

1000T |

﹤150mm |

22 |

3600T |

﹤250mm |

20 |

|

150T |

﹤180mm |

22 |

4000T |

﹤400mm |

20 |

|

1800T |

﹤200mm |

21 |

6500T |

﹤540mm |

19 |

|

2500T |

﹤230mm |

21 |

8000T |

﹤700mm |

16 |

Application status:

Aluminum extruded heat sink is the most common heat sink. Aluminum extrusion molding through molds can achieve complex heat dissipation tooth structure, and the processing cost is relatively low when mass-produced. Due to the influence of the aluminum extrusion process mold multiples, the number and height of heat dissipation teeth are limited to a certain extent, and the heat dissipation capacity is insufficient when facing high-power devices; the mold opening cost of large molds is high, the mold opening cycle is long, and the stability is poor.

Why use extruded radiators?

(1) It is more efficient than the heat sink formed by stamping;

(2) more cost saving than mechanical processing;

(3) A variety of standard shapes and sizes are available;

(4) Easy customization is lighter than copper, with obvious advantages;

(5) The MAX CLIP coupler system does not need to install hardware and tools.

FSW process applied to the large extrusion heat sink which the extruded mold width limisted

The friction welding radiator uses small-size mold extrusion splicing to achieve ultra-large width aluminum profile radiator, which increases the extrusion ratio. At the same time, the small mold also greatly reduces the mold cost, shortens the development cycle and increases the stability of the mold.

Two or more aluminum extrusion semi-finished products are spliced into a larger aluminum extrusion semi-finished product by stir friction welding. The splicing seam is welded by friction welding at high temperature without medium to form an integrated structure. Its heat dissipation effect and structural strength can reach that of aluminum extrusion material. It is then processed into a radiator through subsequent machining, surface treatment and other methods.

Two or more aluminum extruded splices

FSW for large size profiles

Integrated heat sink finished

More varieties Extrusion heat sinks: