Medical Facility Cooling Solution

The components that need heat dissipation in medical equipment mainly include electronic components, motors, sensors and other heat-generating components. If the heat is not dissipated in time, it may cause unstable operation or even damage of the equipment.

With the rapid development of science and technology, the types of medical equipment are increasing, and their applications in medical work are becoming more and more extensive. The temperature requirements in their working environment are also very strict. In order to ensure that medical equipment works in the correct temperature environment, they are usually equipped with cooling and heat dissipation systems. A good cooling and heat dissipation system can ensure the safe and reliable operation of medical equipment, with low energy consumption, low maintenance rate and high work efficiency. Once the cooling and heat dissipation system fails, the equipment components will be seriously heated up due to the heat generated during operation, which will eventually cause abnormal conditions or even damage to the medical equipment. Therefore, the research on the cooling and heat dissipation system of medical equipment is particularly important.

What are the cooling solutions for medical equipment?

The heat source in medical equipment refers to the temperature of some internal parts rising due to rapid rotation or vibration and working under high pressure during the operation of medical equipment. Due to the existence of heat sources inside medical equipment, there are many factors affecting the temperature of internal components of medical equipment, so there are many cooling and heat dissipation measures.

The heat source in medical equipment refers to the temperature of some internal parts rising due to rapid rotation or vibration and working under high pressure during the operation of medical equipment. Due to the existence of heat sources inside medical equipment, there are many factors affecting the temperature of internal components of medical equipment, so there are many cooling and heat dissipation measures.

Characteristics of heat dissipation methods of various medical equipment

Solid heat sink: transfers heat from the heat source to the heat sink through physical contact.

Natural air cooling: uses natural convection and the air cooling effect generated by the fan to dissipate heat.

Water circulation module: removes heat through the water circulation system, and then transfers the heat to the cooling water through the heat exchanger.

Oil circulation module: uses oil as a medium for heat transfer.

TEC circulation module: uses refrigerant circulation for heat transfer.

Air cooling module: removes heat through the airflow generated by the fan.

How to choose the cooling solutions for your medical equipment?

In the face of many heat dissipation methods, different medical equipment adopts different cooling and heat dissipation methods.

Middle and small power medical equipment often uses forced air cooling for heat dissipation;

Electronic components or parts that work under high temperature conditions and have a high heat generation rate during work are more suitable for cooling with liquid cooling with relatively high cooling efficiency;

For components with a high heat generation rate during work, when conventional cooling methods cannot meet the requirements, other cooling methods such as evaporative cooling, heat pipes, boiling evaporation, microchannel cooling or jet cooling or even thermoelectric cooling can be used for cooling.

Many large medical equipment will adopt two or more heat dissipation methods to cool and dissipate internal components.

In the evolution of medical devices, passive thermal management is clearly a major factor in helping to ensure the precision and advanced functionality of current medical devices, and to take these capabilities a step further. Passive thermal management solutions offer valuable advantages in terms of saving space, reducing weight, and lowering maintenance costs. As the functionality and computing power of electronic devices continue to increase, generating more heat that needs to be dissipated, and miniaturization is gradually reducing the space available for the deployment of thermal management components, innovative thermal technologies will play an important role in the development of future medical devices.

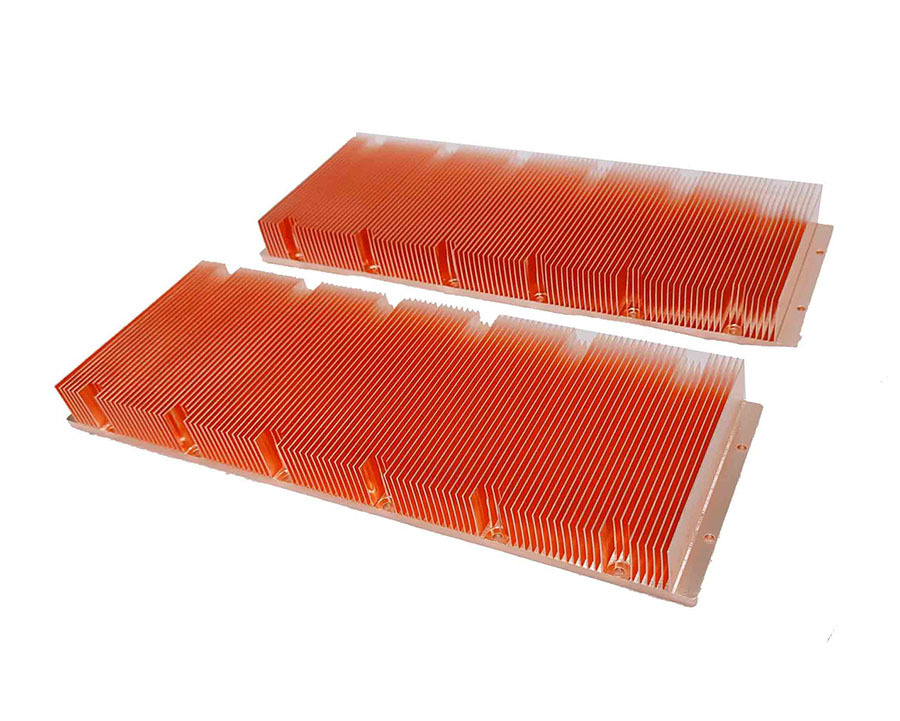

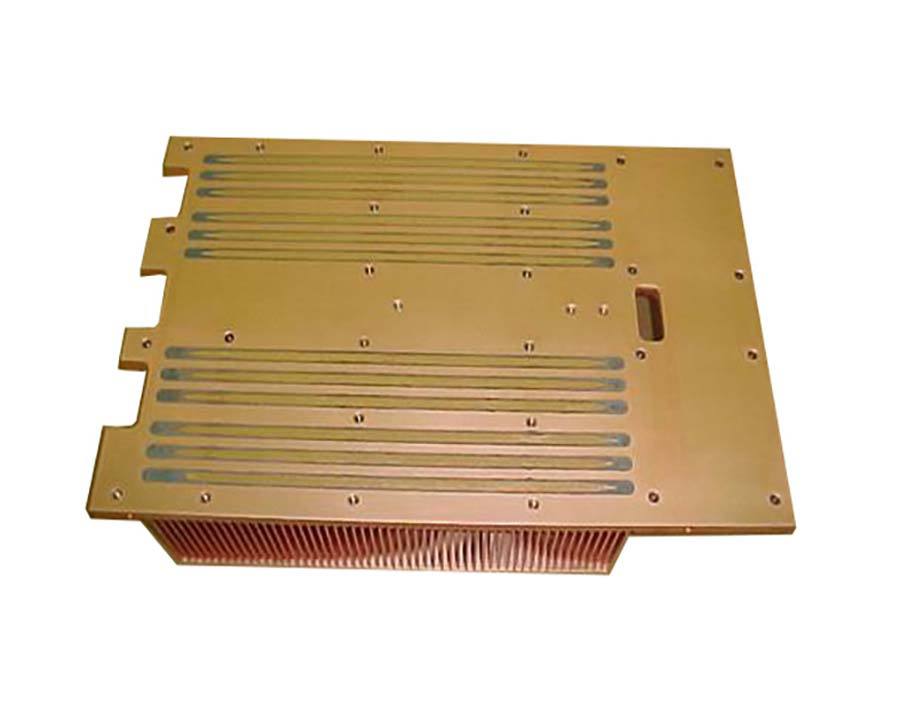

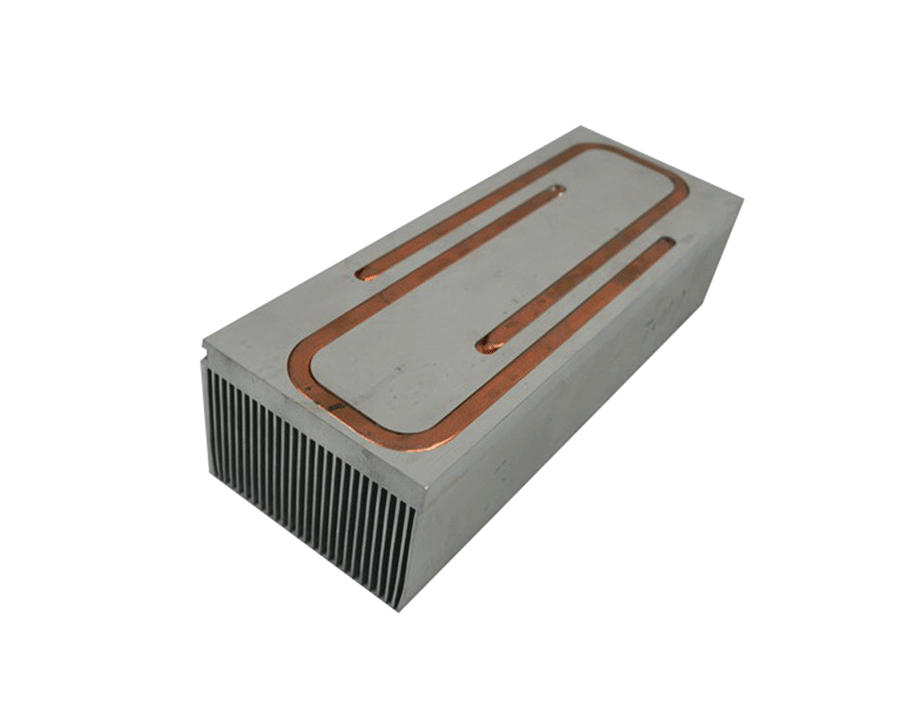

What are the process types of commonly used forced air cooling heat sinks?

There are mainly CNC processing types, aluminum extrusion, die casting, Skived process, Bonded fins, welding combination types or modules with heat pipes, etc.

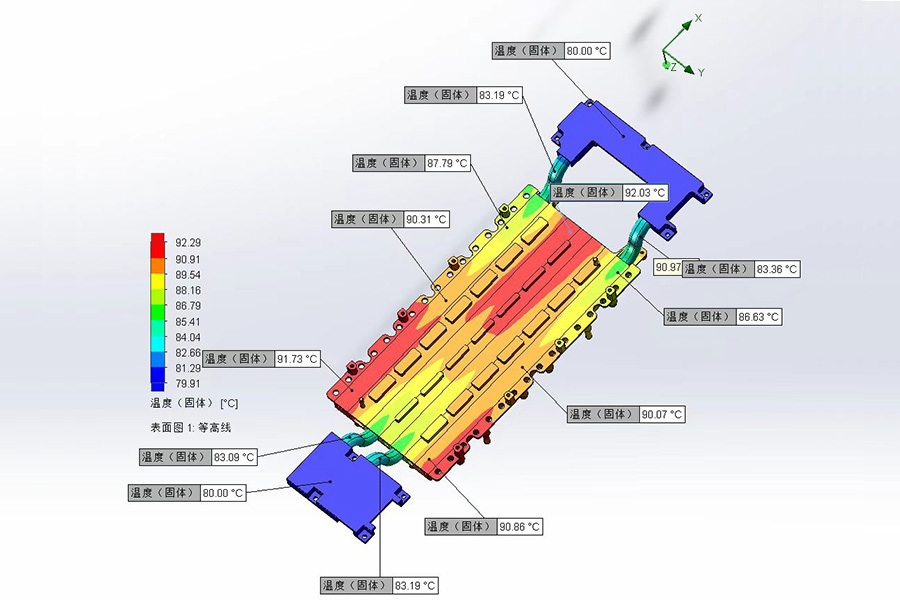

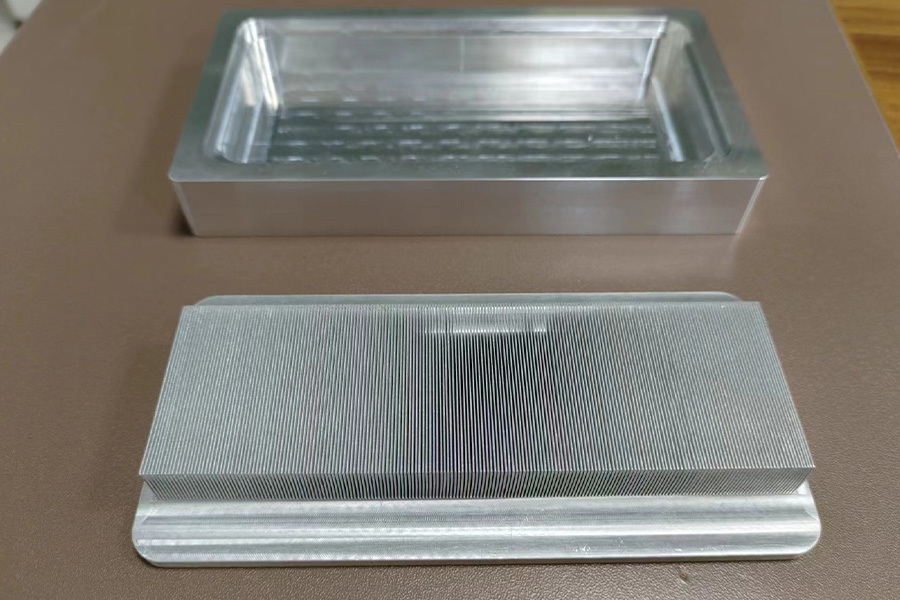

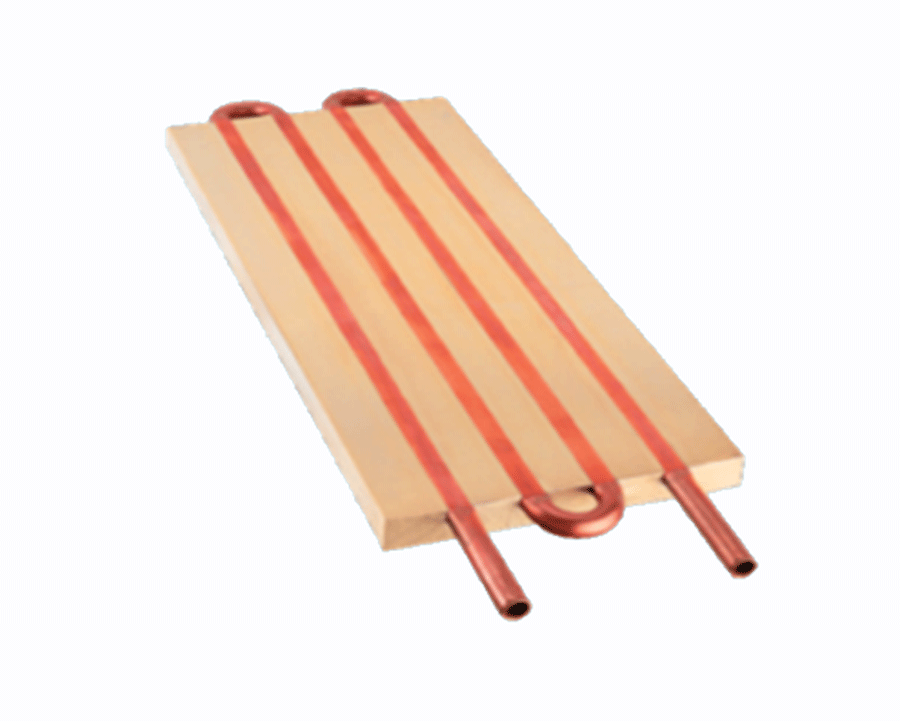

Liquid cooling plate used for Medical

With the continuous development of electronic assembly technology, the size of electronic equipment tends to be miniaturized, the system tends to be complex, and high heat density has become an irresistible development trend. It adopts full-coverage water channel heat dissipation, and the heat dissipation effect is more comprehensive.

From imaging equipment to surgical instruments to automatic immunity, powerful medical technology is impressive, however. The greater the power of the equipment means the greater the heat it generates, and generally speaking, it has to be dissipated in a smaller and smaller space (because the size of the equipment is getting smaller and smaller). As our requirements for the accuracy and reliability of medical equipment become higher and higher, heat dissipation control becomes more important. Here we believe that water cooling will be a mainstream trend, with precise core heat dissipation cold heads and smaller area.

More varieties Thermal Products: