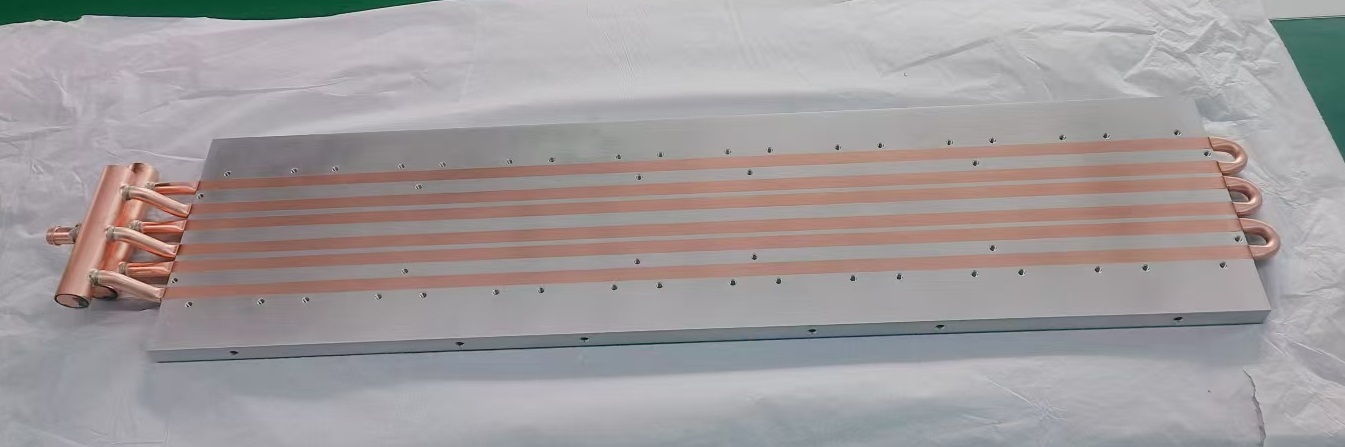

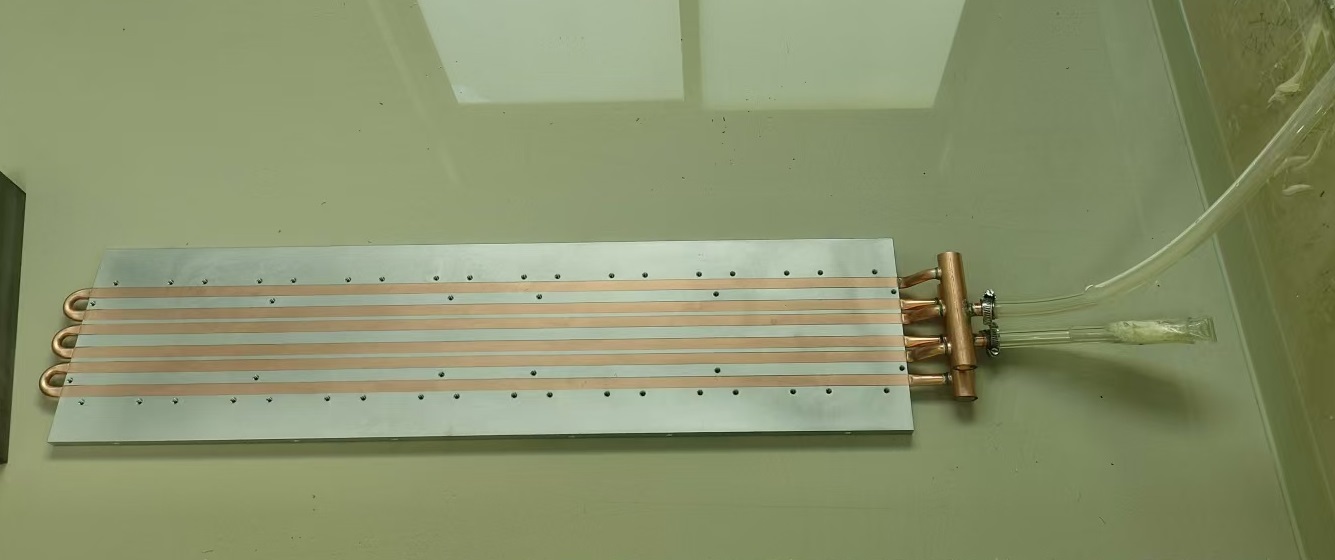

How does the embedded copper tube liquid cooling plate applied to the IGBT liquid cooling system?

Embedded copper tube liquid cooling plate plays an important role in the application of high power IGBT cooling system. The following is a related introduction:

Working principle

The copper tube water cooling plate uses the high specific heat capacity of water to remove the heat generated by the IGBT during operation through circulating water. The water cooling plate is usually composed of a copper tube and a metal substrate. Water flows through the copper tube. The IGBT module is installed on the metal substrate. The heat is transferred to the copper tube through the substrate and then taken away by the circulating water.

Advantages

- Efficient heat dissipation: It can effectively dissipate the high heat generated by the IGBT quickly, ensure that the IGBT works within a suitable temperature range, and improve its performance and reliability.

- Compact structure: It can be customized according to the layout of the IGBT module to save space and is suitable for high-power equipment with limited space.

- Good stability: The water cooling system operates stably and can reliably dissipate heat for the IGBT for a long time, reducing equipment failures caused by heat dissipation problems.

Application scenarios

- Industrial inverter: In high-power industrial inverters, the IGBT module will generate a lot of heat. The copper tube water cooling plate can ensure its stable operation and improve the efficiency and life of the inverter.

- New energy vehicles: The drive motor controller used in electric vehicles can efficiently dissipate heat for the IGBT modules therein, ensuring the performance of the vehicle under various working conditions.

- Wind power generation: The IGBT modules in the wind power converter dissipate heat through the copper tube water cooling plate, which can adapt to the harsh outdoor environment and ensure the stable operation of the power generation system.

What's the production process to make a embedded copper tube liquid cold plate? Please contact us with any interest!

PREVIOUS:

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?