Copper Tube Cold Plate

How to realize the production and manufacturing of the diversified flow channels of copper tube liquid cooling plates?

Vansim's many years of manufacturing experience will help you realize your design with the copper tube.

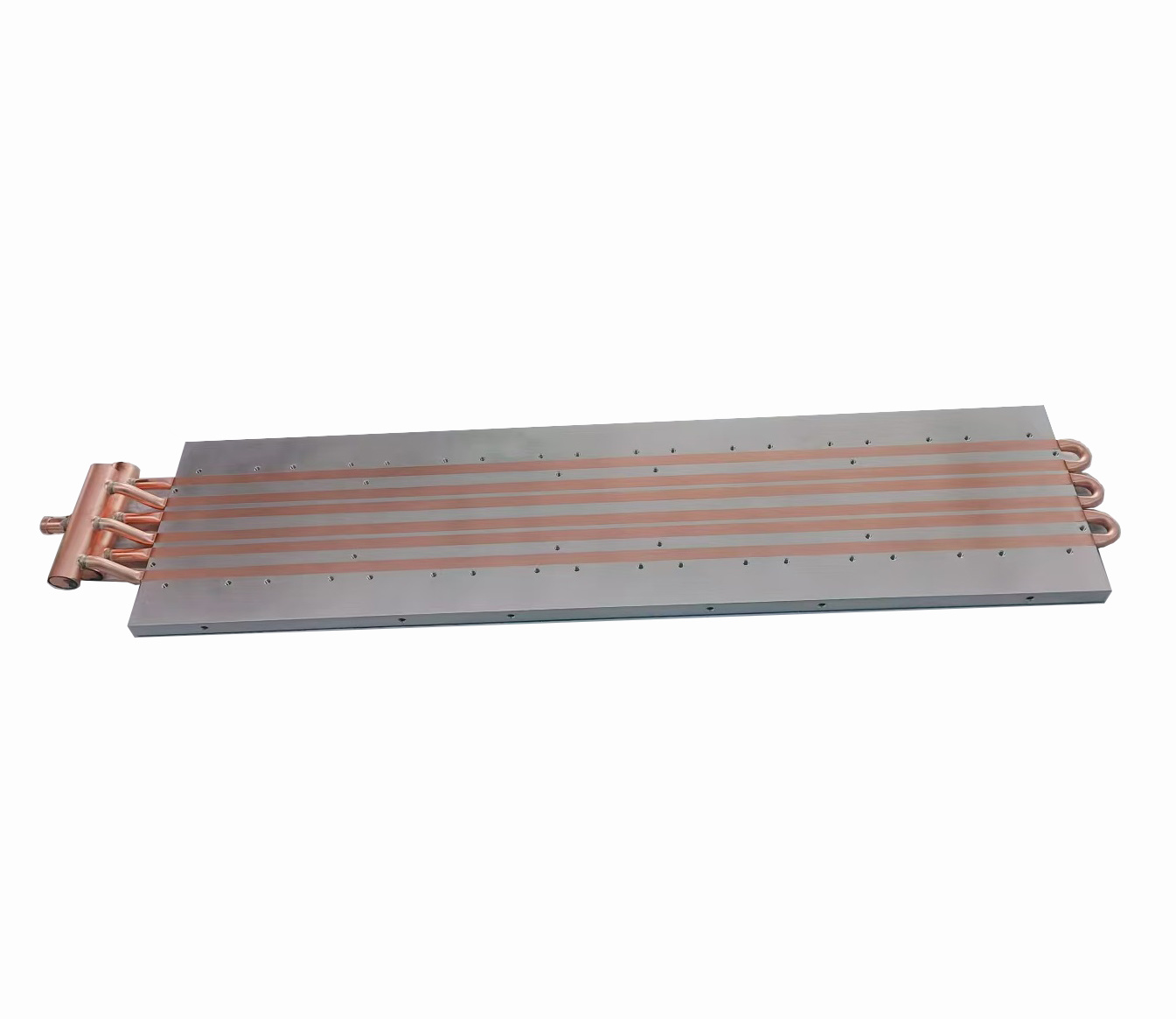

Copper Tube Cold Plate

Process introduction:

The buried tube liquid cooling plate process is the most commonly used liquid cooling plate manufacturing process. Generally speaking, it is an aluminum base plate embedded with a copper tube assembly, that is, the aluminum base plate is milled with CNC, and then the bent copper tube and the inlet and outlet joint assembly are pressed into the groove of the aluminum base plate, and then machined and surface treated to form a liquid cooling plate.

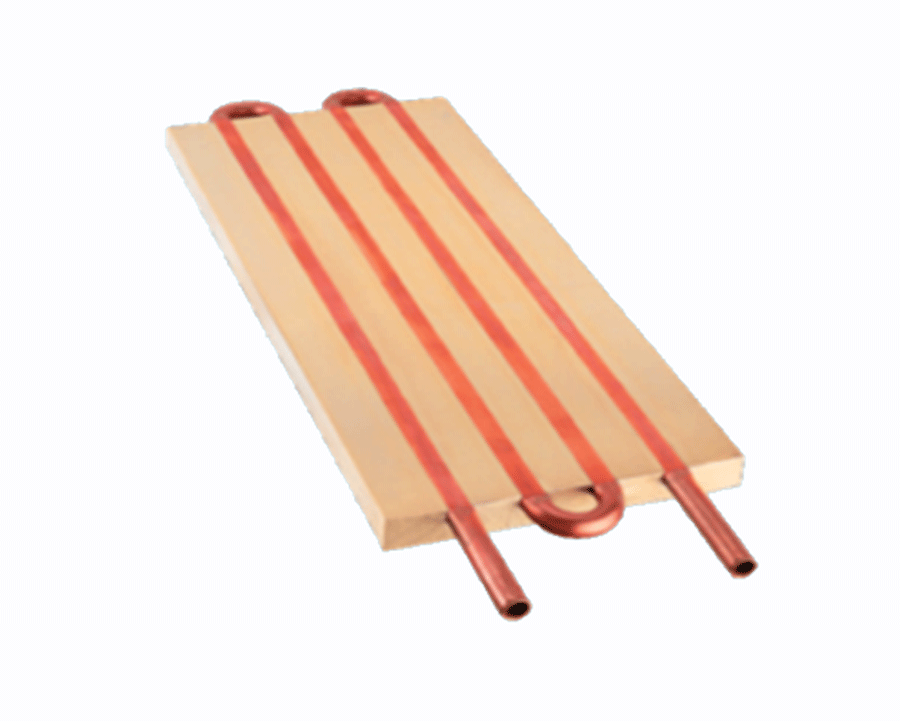

Copper tube and Aluminum base

Buried pipe cross section

Design Reference:

Diameter of copper pipe commonly used in buried pipe technology:

Φ6mm、 Φ6.35mm、 Φ8mm 、 Φ9.52mm 、 Φ10mm 、 Φ12mm 、 Φ12.7mm 、 Φ16mm

Buried pipe principle

Regarding the relationship between the copper tube diameter and the copper tube flow channel bending of the water cooling plate, please contact Vansim's technical team for answers!

Contact Us >>Application Status:

The buried tube liquid cooling plate is simple to process and has a stable product structure. It is the earliest to be applied and has mature technology. It is suitable for mass production. The copper tube flow channel has strong corrosion resistance. The layout of the liquid cooling flow channel needs to take into account the limitation of the copper tube bending radius. The liquid cooling flow channel is relatively simple.

Copper tube liquid cold plate applied to Medical facility

Medical electronic equipment usually integrates a large number of electronic components, which generate a lot of heat during operation. If the heat cannot be dissipated in time, the temperature of the components will rise, which will affect the performance and life of the equipment, and even cause failures. Therefore, Thermal design is particularly important in the medical PCBA processing process.

The efficient and stable heat dissipation effect makes the liquid cooling system widely used in the medical field.

Double flow channel copper tube + aluminum base

After buried pipes and filled the epoxy

Then CNC machining complete copper tube liquid cold plate

Copper tube liquid cooling plate used for fiber laser and radar transmitter

The copper tube water cooling plate uses heat-conducting materials (usually copper or aluminum) to transfer the heat of the pump source from the copper tube water cooling plate to the water flow, thereby quickly taking away the heat and keeping the operating temperature of the laser within a low range. High structural strength: In order to strengthen the structural strength of the copper tube and the radiator and improve the thermal conductivity, a thermal conductive structural adhesive is usually used to bond the copper tube and the radiator together to fill the processing gap and improve the thermal conductivity.

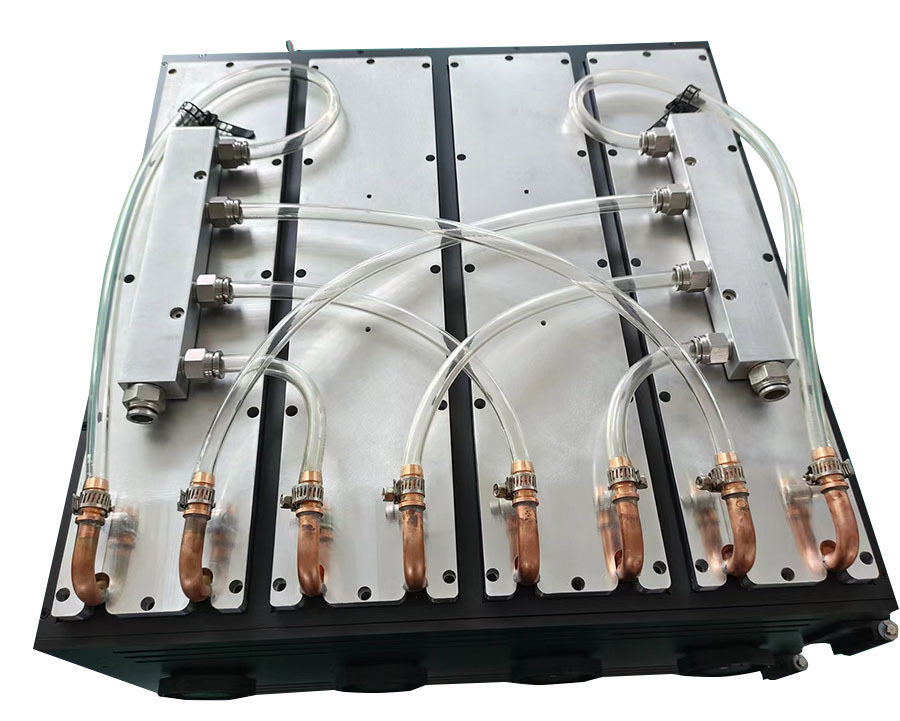

Copper tube liquid cold plate applied to energy storage cooling system

Liquid cooling is suitable for large-scale, high-energy-density energy storage projects, especially in situations where the battery pack has high energy density, fast charging and discharging speed, and large ambient temperature changes. The advantages of liquid cooling are particularly obvious. For example, in large-scale energy storage power stations, outdoor energy storage cabinets need to provide long-term energy storage services for the power grid to ensure the stability of local power supply.

These energy storage devices usually have the characteristics of high power density and high energy density, so liquid cooling technology is widely used due to its efficient heat dissipation performance. In addition, in wind farms and solar power stations, outdoor energy storage cabinets also need to store a large amount of electricity to balance the fluctuations in power generation, and liquid cooling technology has also become the first choice.

Copper tube liquid cooling plate used for Semiconductor Industry

The application of copper tube water cooling plates in heat dissipation in the semiconductor industry is mainly reflected in its efficient thermal conductivity and flexibility of structural design.

In the semiconductor manufacturing process, the high temperature environment has extremely high requirements for equipment. Copper tube water cooling plates can effectively reduce the temperature of manufacturing equipment and ensure the stability of the manufacturing process and product quality.

The application scenarios of copper tube water cooling plates in the semiconductor industry are not limited to semiconductor manufacturing equipment, but also suitable for integrated circuit semiconductor components, chips, semiconductor refrigeration, etc.

Different flow channel structures to meet your different design needs!

More varieties Copper tube liquid cold plates :