Skived fin Heat Sinks

Vansim's skived machines and technology can help you develop and apply data center server cooling systems and inverter heat sinks

Skived fin Heat Sinks

Process introduction:

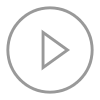

Skiving fin is the process of the long strips of plate are cut into relatively straight sheets at a certain angle using a special tool through mechanical action. Repeated cutting forms a uniformly ordered gap heat dissipation fin structure, which is then processed into a radiator through subsequent cutting, machining, surface treatment and other methods.

Shovel tooth diagram

Shovel tooth principle

Skiving Design Reference:

The skived fin technology can process a variety of materials: AL1060, Al6061, Al6063, Cu1100, Cu1020.

Skiving fin AL Process parameters:

|

Base thickness |

Fin length |

Fin height |

Fin thickness |

Fin gap |

Product length |

|

1~30mm |

﹤700mm |

﹤150mm |

0.05~2.0mm |

0.1~6.5mm |

1000mm |

Skiving fin CU Process parameters:

|

Base thickness |

Fin length |

Fin height |

Fin thickness |

Fin gap |

Product length |

|

1~30mm |

﹤550mm |

﹤120mm |

0.05~1.5mm |

0.1~6.5mm |

500mm |

Vansim’s years of experience in shovel tooth processing provide your products with stable quality skived fin heat sink output.

Contact Us >>Skived fin Heat sinks Application status:

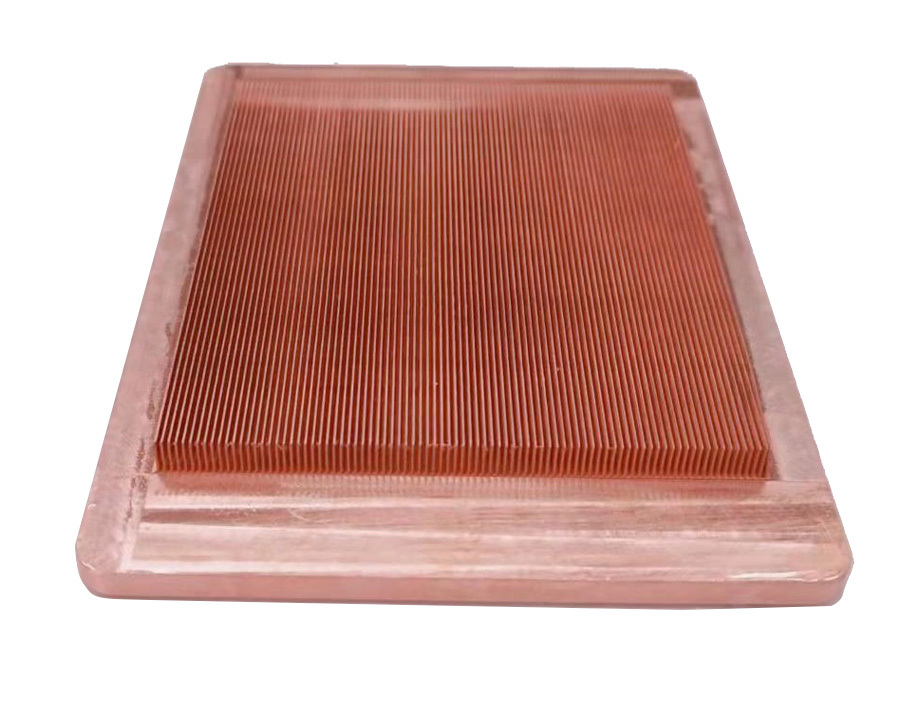

The skived fins process can obtain heat dissipation teeth with higher teeth and smaller gaps, thereby obtaining a larger heat dissipation area to improve the heat dissipation effect. The heat dissipation teeth and the base plate are integrally processed and formed without interface thermal resistance. With its excellent heat dissipation capacity, the skived tooth heat sink has become a widely used solution in the field of high-power air cooling and server liquid cooling modules.

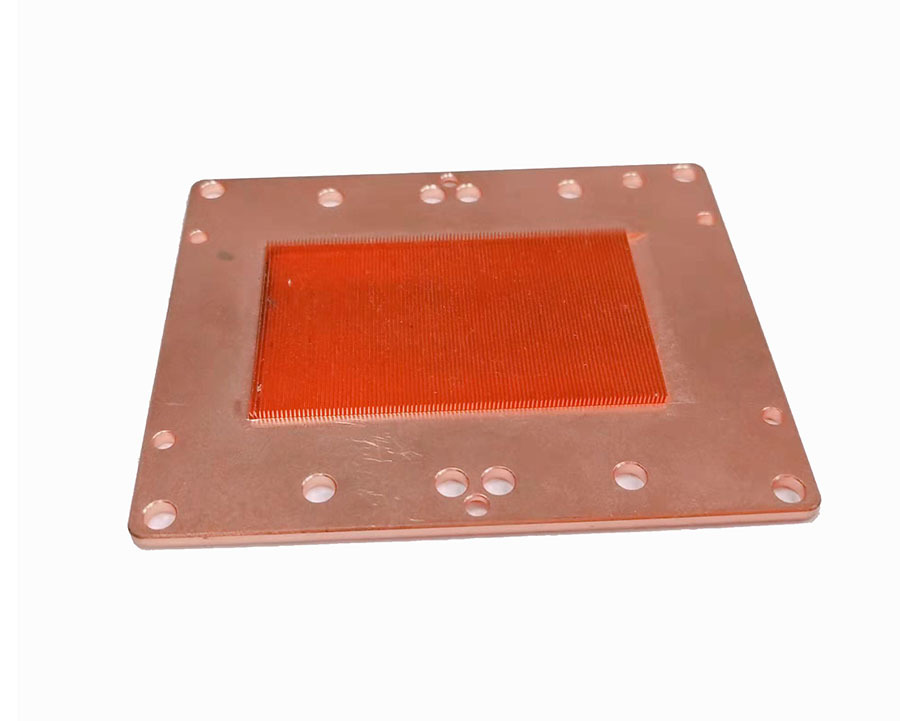

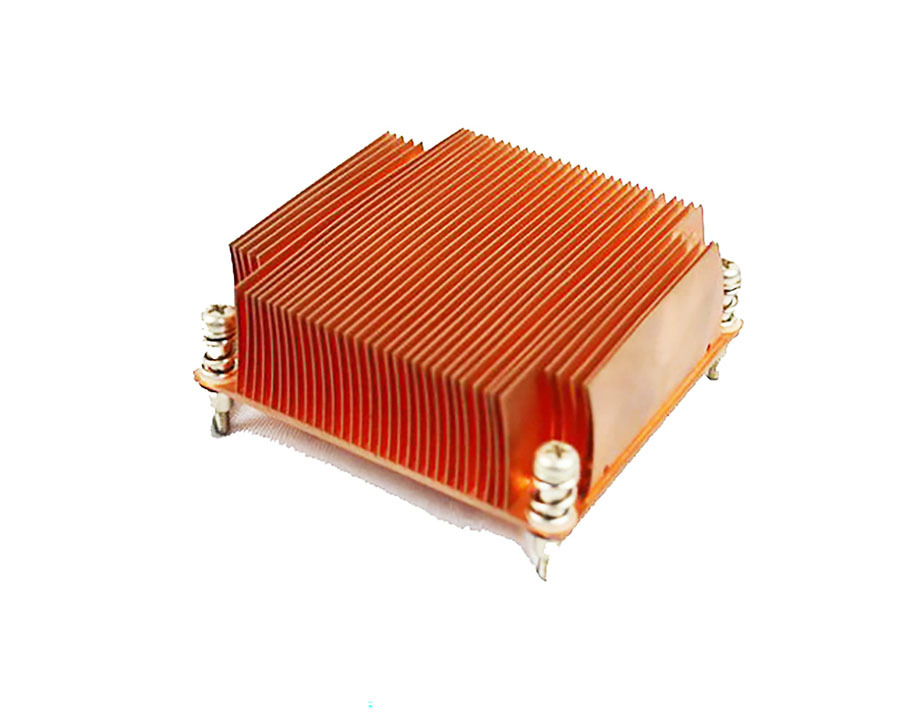

High-density fins of copper skived fins heat sink for PC water block

Charging point heat dissipation mechanism and its importance: What are the risks that heat accumulation may bring?

The specific application of heat pipe heatsink in charging point is: the heat absorbing plate is closely fitted or close to the heating components inside the charging pile, and the heat is transferred to the condensation end through the heat pipe technology, and then the heat is dissipated into the air through the heatsink. This design not only improves the heat dissipation efficiency, but also avoids the entry of pollutants such as dust, ensuring the cleanliness and safety of the charging pile.

PC Water Block

The advantages of heat pipe heat sinks include high thermal conductivity, good heat dissipation performance and long life. It can work stably under high power conditions and is suitable for high-load equipment such as charging piles. By using heat pipe radiators, the heat dissipation problem of charging piles has been effectively solved, thereby improving the overall operating efficiency and safety.

Servers Liquid cooling plate

Micro-channel copper skived fin heat sink for data center servers liquid cooling

With the continuous expansion of the scale and capacity of data centers, integrated CPU packaging and cooling technologies represented by micro-channel flow tubes and spray jets have the advantages of strong heat transfer capacity, compact structure, good adaptability, controllable cost and low energy consumption. It is expected to become an effective way to solve the heat dissipation of high heat flux density server CPUs in the future. High-density skived heat sinks are the most commonly used and cost-effective cold plates to promote the development of micro-channel water cooling.

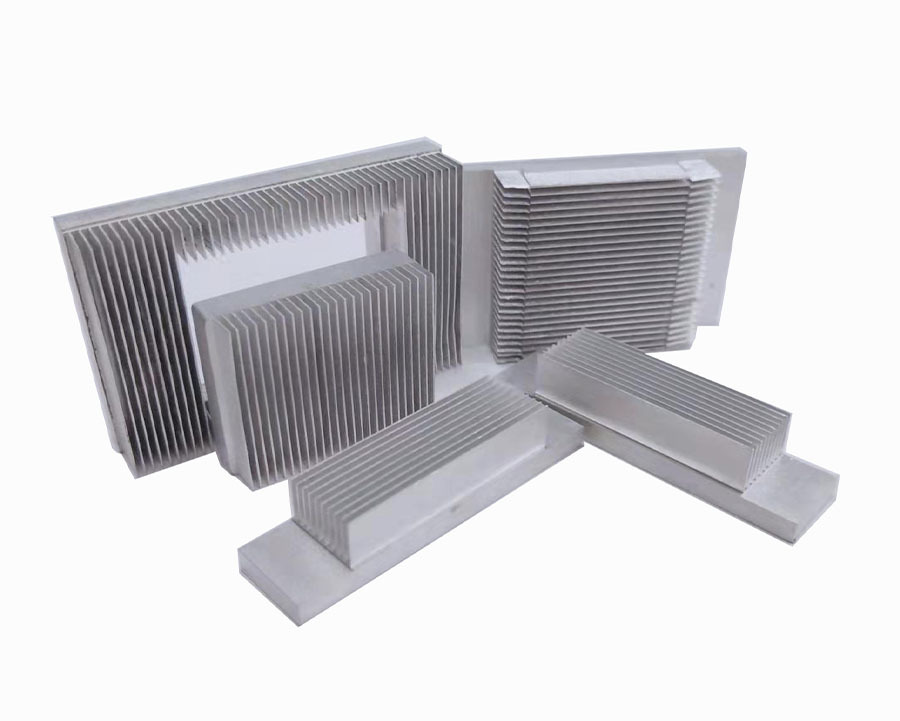

Aluminum/Copper skived fin heatsinks applied for New energy inverters , Laser cooling,Electrical heat dissipation, ect.

High-density skived heat sinks stand out among many cooling solutions with their advantages of high efficiency, light weight, high reliability, strong compatibility and optimized design, and become an ideal choice for cooling high-power devices.

Vansim's main production process is skived process. Our production capacity will provide strong guarantees for your cooling design and make your cooling solution more competitive in the market.

Skived heat sinks are used for plant lights or mining lights

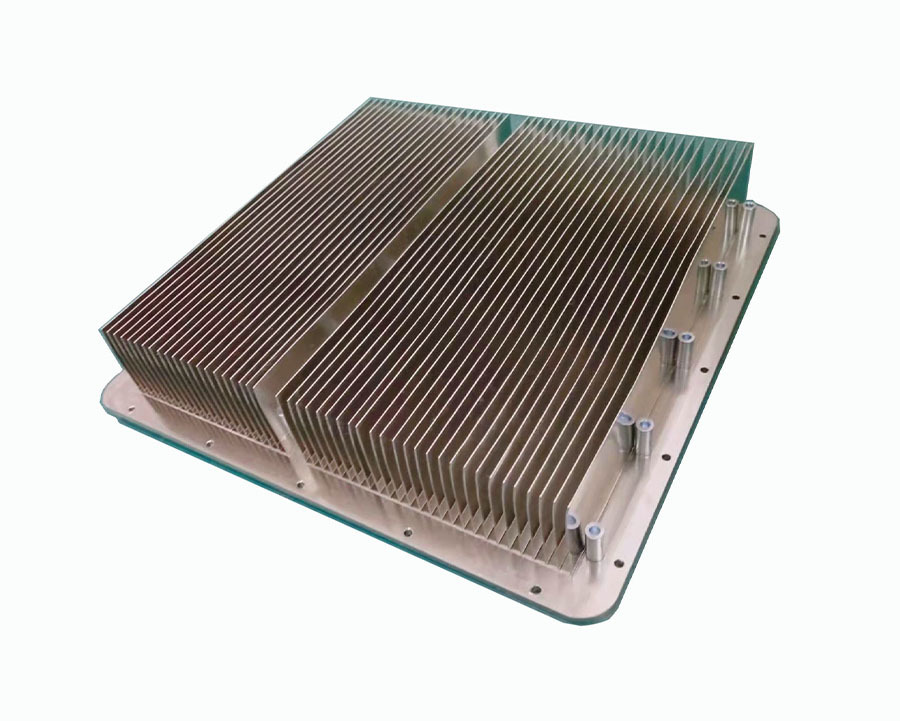

FSW Machining assisst the skived fin heat sink structure limited project

Due to the process characteristics of the skived heat sink, all the fin gap is the same. If the heat dissipation design needs to add thicker columns or fins in the middle of the teeth, the skived process itself cannot do it. So what method can be used to make the heat dissipation design realize production?

We use CNC processing to clear the position where the column needs to be added, and then on this basis, FSW is used to make the thick column and the skived heat sink become one, and finally realize the production of the overall heat dissipation design.

Skived fin heat sink is an efficient heat dissipation solution, especially suitable for high-power equipment such as plant lights. Skived heat sink uses high-precision cutting technology to cut a whole piece of aluminum or copper into fins with standard spacing. This design greatly increases the heat dissipation area and improves the heat dissipation efficiency.

The application of Skived heat sink in plant lights is mainly reflected in its efficient heat dissipation performance. Plant lights usually need to be used continuously for a long time and have high requirements for heat dissipation. Skived heat sink can effectively reduce the temperature of LED light source, extend service life and improve light efficiency by increasing the heat dissipation area and optimizing the heat conduction.

Skived fin heatsinks assisst liquid cooling system

Air-cooled and water-cooled hybrid radiators use a hybrid air-water design to provide better heat dissipation and user experience. This combined radiator design may include the use of a water cooling system in key heat source areas and an air cooling design in other areas. This can take into account both efficient heat dissipation and lower noise levels while avoiding the limitations of a single heat dissipation method. Different soldering or friction welding processes can be used to combine the heat sink and the water cooling plate to meet the design of the heat dissipation structure.

Skived fin Heat Sinks For Micro-channel liquid water blocks

Skived fin Heat Sinks For Electrical Air Cooling System