Advanced Embedded Heat Pipe Technology in Skived Heat Sinks for Enhanced Performance of Inverters and Converters

In high-power electrical systems such as **inverters** and **converters**, efficient thermal management is critical to ensuring reliability, longevity, and peak performance. As industries push toward higher power densities and compact designs, traditional cooling solutions often fall short. Enter the next generation of thermal management: **Vansim's skived-fin heat sinks with pressed heat pipe technology**, a breakthrough combination engineered to meet the demanding needs of modern power electronics.

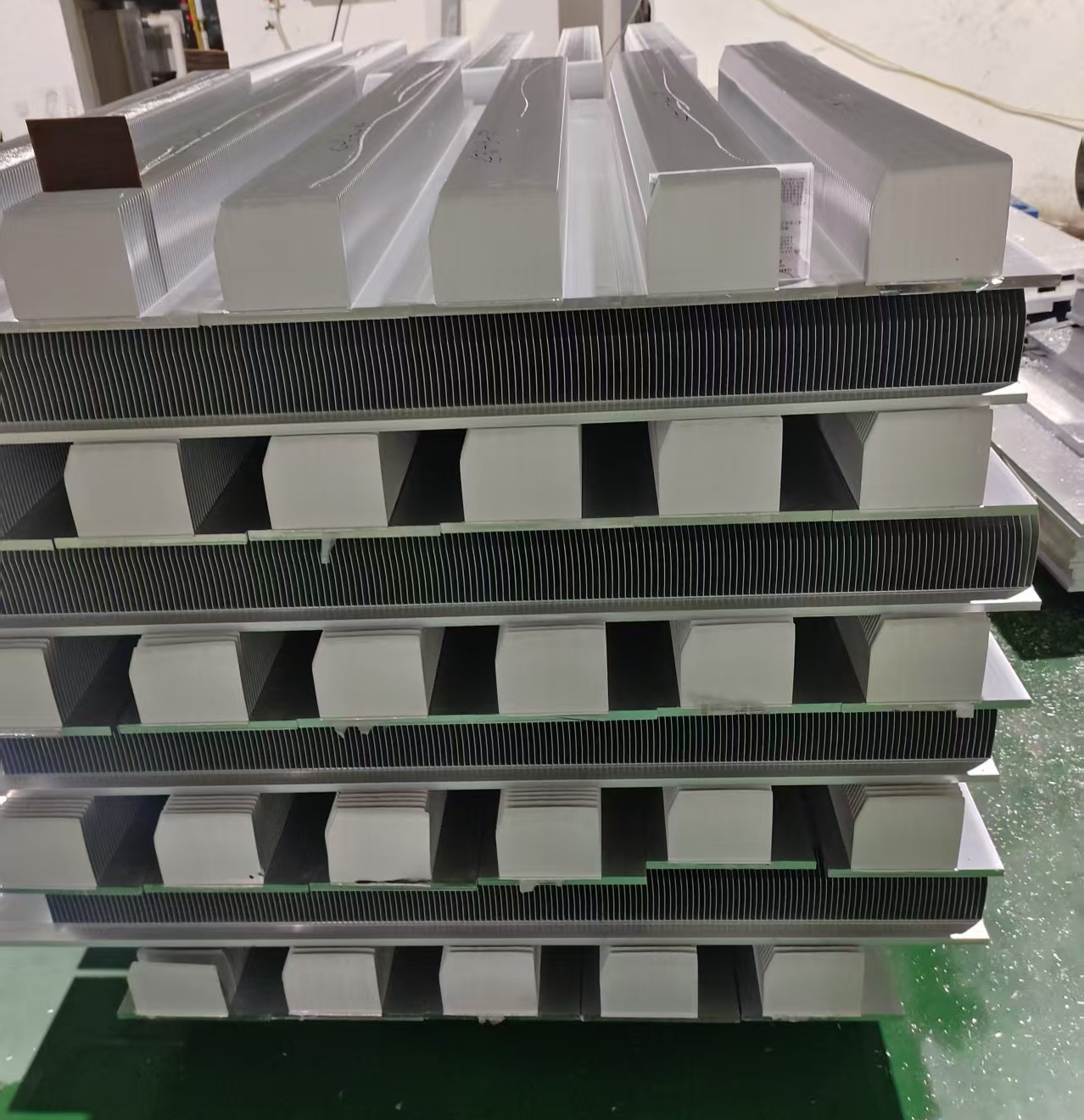

**The Power of Skiving Process: Precision Meets Performance**

The **skiving process** is a cutting-edge manufacturing technique that creates ultra-thin, high-density fins from a single block of metal (typically aluminum or copper). Unlike traditional extrusion or stamping methods, skiving enables:

- **Exceptional fin density**: Thin, closely spaced fins maximize surface area for superior heat dissipation.

- **Structural integrity**: Seamless base-to-fin integration eliminates thermal resistance gaps.

- **Customizable geometry**: Tailored fin heights, thicknesses, and patterns to match specific thermal loads.

This precision makes skived heat sinks ideal for high-heat-flux applications, where even minor inefficiencies can lead to overheating and component failure.

|  |

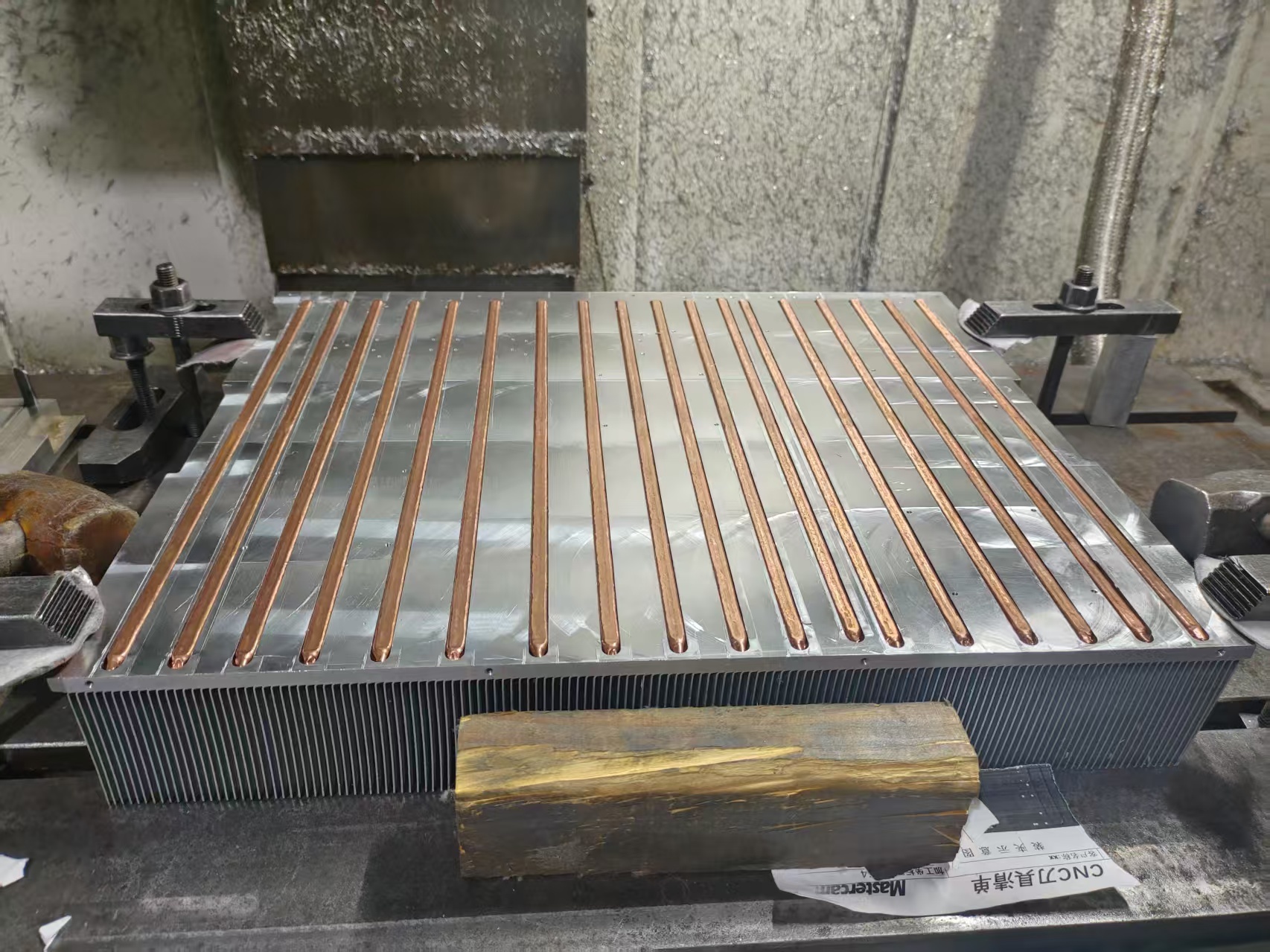

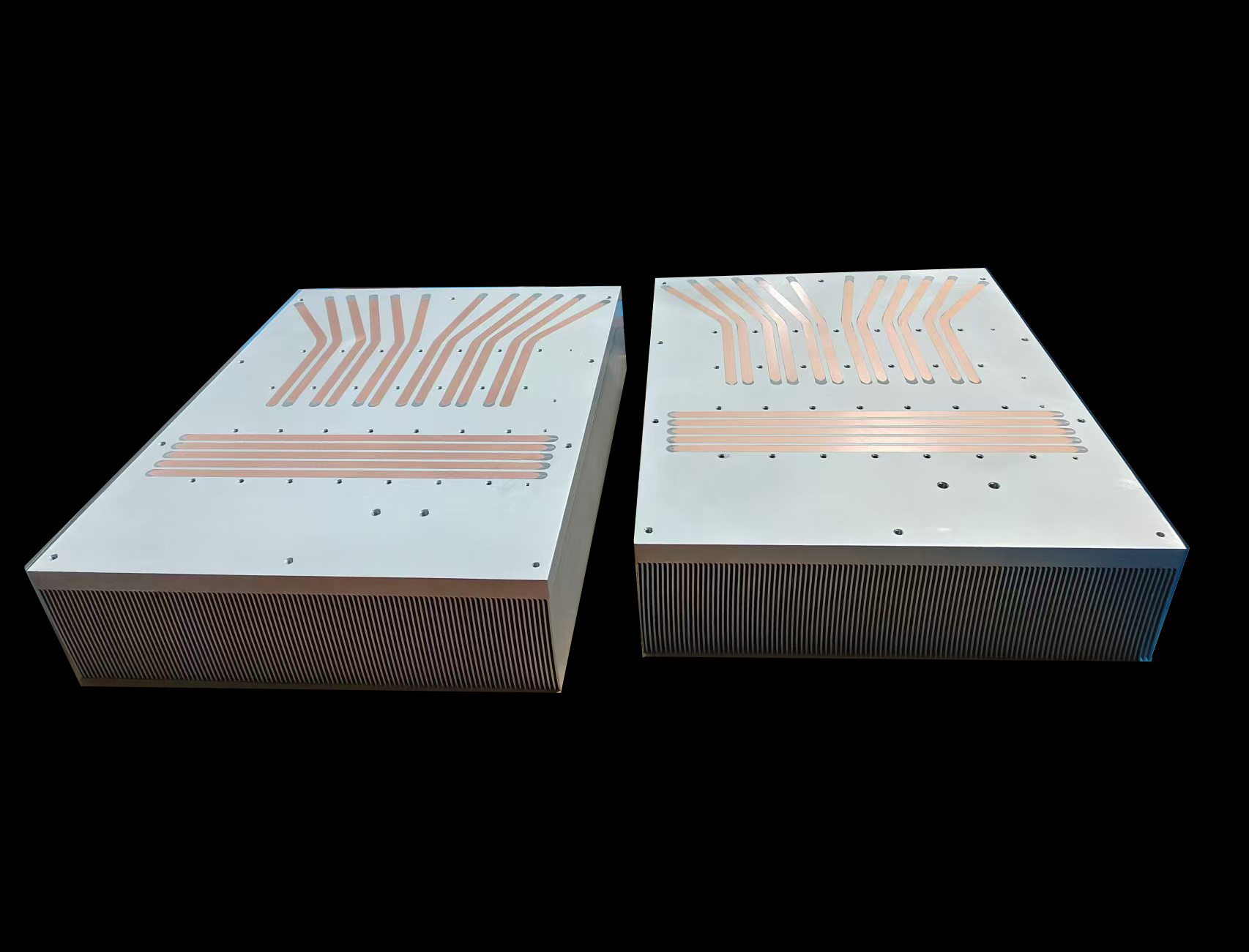

**Embedded heat pipes heat sink: Supercharging Thermal Conductivity**

To further enhance performance, **pressed heat pipe technology** is integrated into the skived heat sink base. Heat pipes are highly efficient thermal conduits that rapidly transfer heat from hotspots to cooler areas of the sink. The pressing process embeds these pipes directly into the heat sink’s baseplate, achieving:

- **Instant heat redistribution**: Phase-change principles in heat pipes enable near-instantaneous heat spread across the entire sink.

- **Higher thermal capacity**: Effective handling of localized high temperatures common in IGBTs, MOSFETs, and diodes.

- **Compact design**: Eliminates bulky auxiliary cooling systems while maintaining unmatched efficiency.

**Why Inverters and Converters Demand This Innovation**

Inverters and converters are cornerstones of industries like renewable energy, industrial motor drives, and power transmission. However, their power semiconductor devices (e.g., SiC, GaN) generate intense heat during operation. Conventional cooling methods struggle to balance size, weight, and performance—especially in applications such as:

- **Solar/wind inverters**: High ambient temperatures and variable loads demand robust, maintenance-free cooling.

- **Industrial rectifiers**: High-current operations require stable thermal management to prevent downtime.

- **EV charging systems**: Compact designs need lightweight yet powerful heat dissipation.

Skived heat sinks with pressed heat pipes address these challenges by:

✅ **Reducing operating temperatures** by up to 30% compared to traditional solutions.

✅ **Enabling higher power densities** without compromising footprint.

✅ **Extending component lifespan** by minimizing thermal stress on critical parts.

PREVIOUS:

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?