FSW Liquid Cold Plate for Battery Cooling System

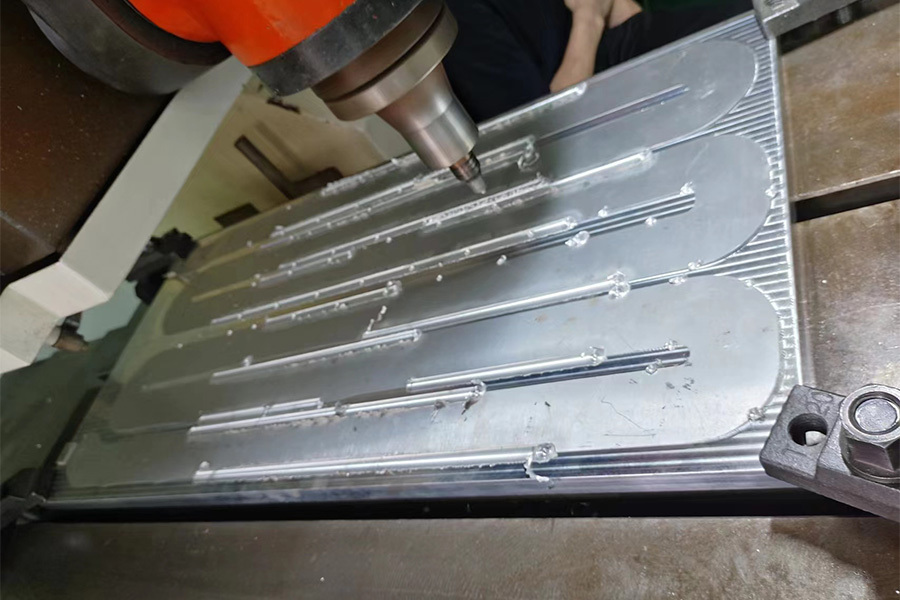

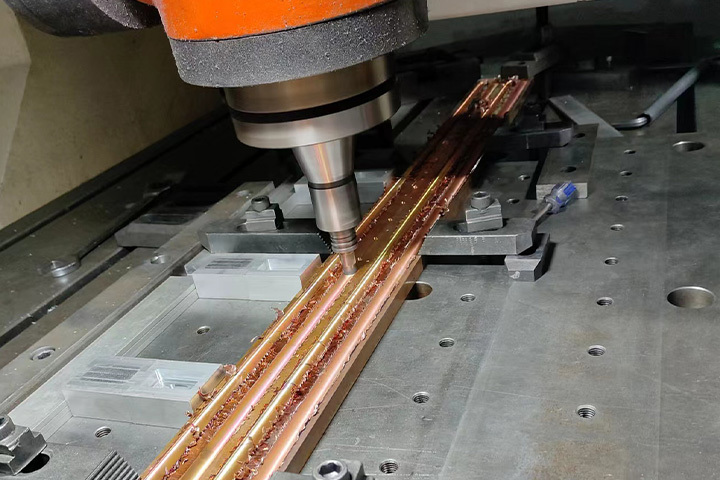

Friction Stir Welding (FSW) is a solid-state joining process that utilizes a rotating tool to generate frictional heat at the interface of two materials, typically metals. The heat softens the material, allowing it to be mixed and joined without reaching the melting point. This process results in a strong, defect-free bond with excellent mechanical properties.

|  |

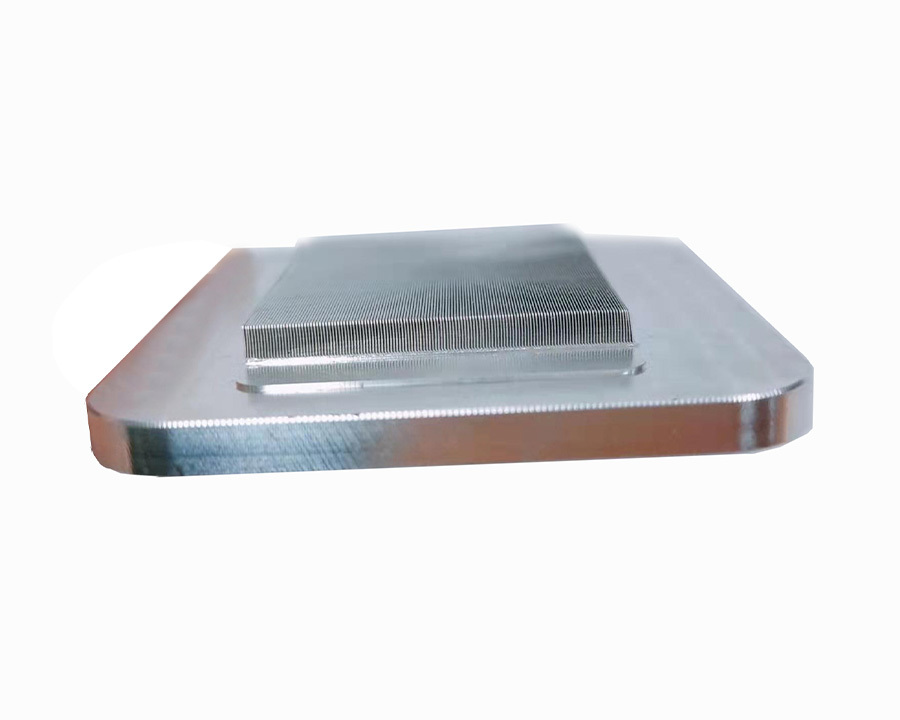

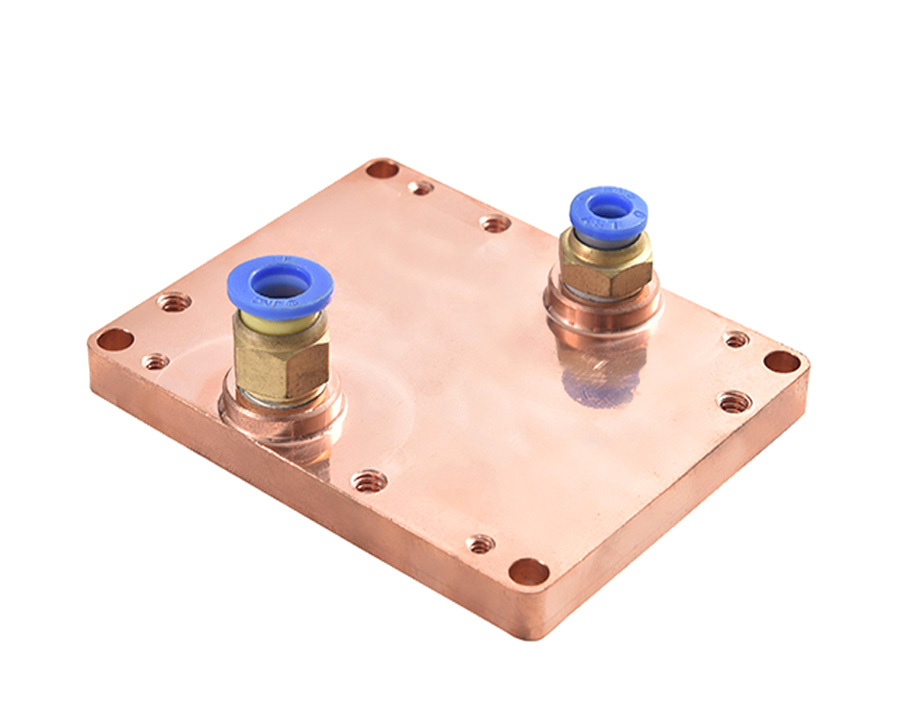

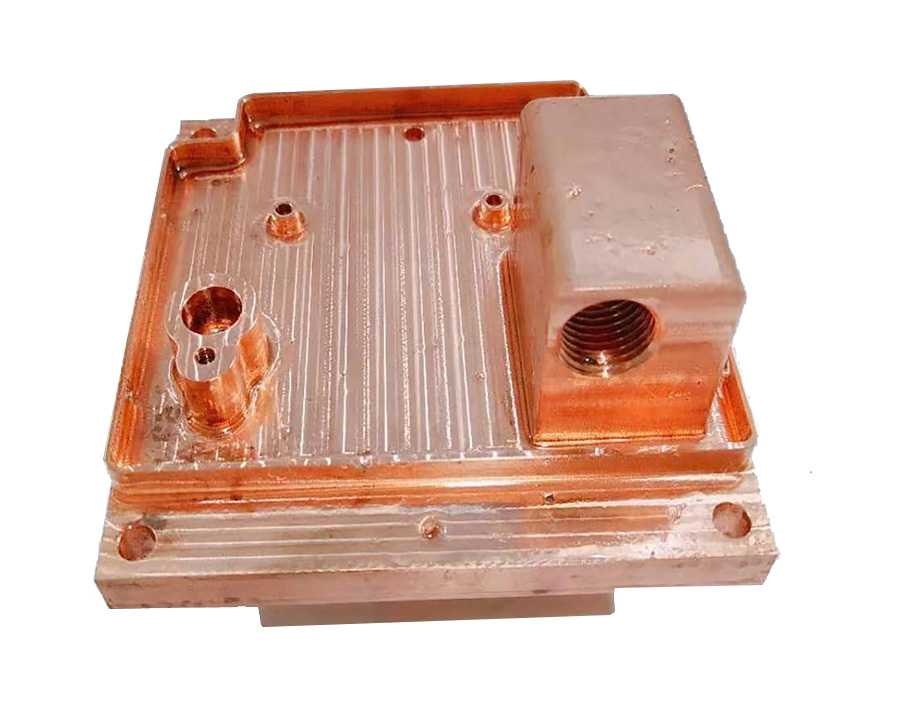

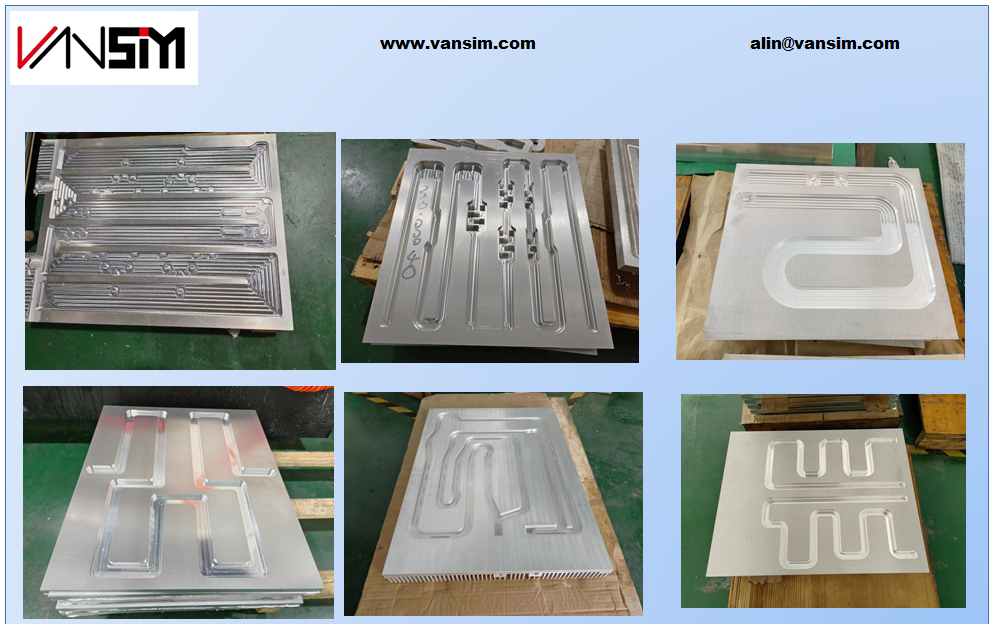

Flexible flow channels is the great advantages for the liquid cooling plate design! Both aluminum and copper material can be avaliable!

**Advantages of FSW Liquid Cold Plates**

1. **Enhanced Thermal Performance**: The ability to create complex channel geometries through FSW significantly enhances the thermal performance of liquid cold plates. The increased surface area allows for more effective heat transfer, which is critical in maintaining optimal battery temperatures.

FSW liquid cold plates are particularly well-suited for use in battery cooling systems across various applications.

1. **Electric Vehicles**: In the automotive industry, maintaining optimal battery temperatures is crucial for performance and longevity. FSW liquid cold plates can efficiently dissipate heat generated during charging and discharging cycles, ensuring that batteries operate within safe temperature limits.

2. **Renewable Energy Storage**: As the adoption of renewable energy sources increases, so does the need for efficient energy storage solutions. FSW liquid cold plates can be integrated into battery systems for solar and wind energy storage, helping to manage heat and improve the overall efficiency of these systems.

3. **Consumer Electronics**: The demand for high-performance batteries in consumer electronics has also risen. FSW liquid cold plates can be employed in laptops, smartphones, and other devices to enhance thermal management, ensuring that devices remain cool during operation.

FSW Liquid cold plate for battery cooling system

Contact Us

Classification