How does FSW process working for the cooling solutions?

How does FSW process working for the cooling solutions? And what can Vansim's friction stir welding (FSW) technology do?

Friction Stir Welding (FSW) is applied in liquid cooling solutions:The application of friction welding technology in cooling solutions is mostly for water cooling solution. This is because the welding process can be adapted to manufacturing flexible and complex structure flow channels for liquid cold plates.

1, FSW process applied for the aluminum liquid cold plate, Widely used for the battery cooling, Laser liquid cooling system,semiconductor cooling,IGBT cooling,Liquid-cooled electronic control box,Ect.

2, FSW process applied for the copper cold plates or copper water block, Widely used for the high power IGBT cooling,CPU liquid cooling, PC cooling or date center water cooling system, Ect.

3, The processing of the base plate and the cover plate for the cold plates involves many different manufacturing techniques.

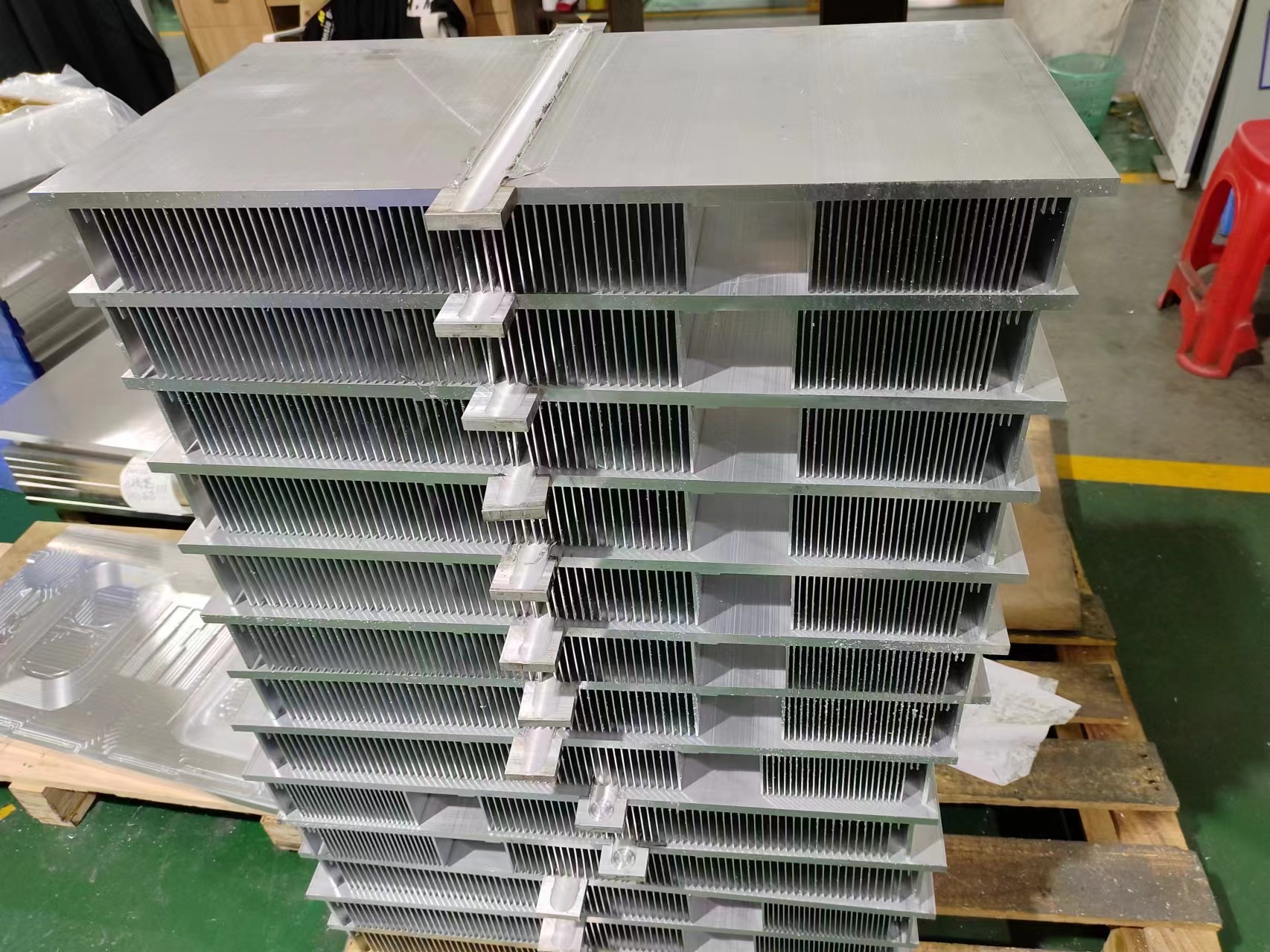

For excample: 1) The skived fins heat sink or extrusion heat sinks as the fins channels cover;

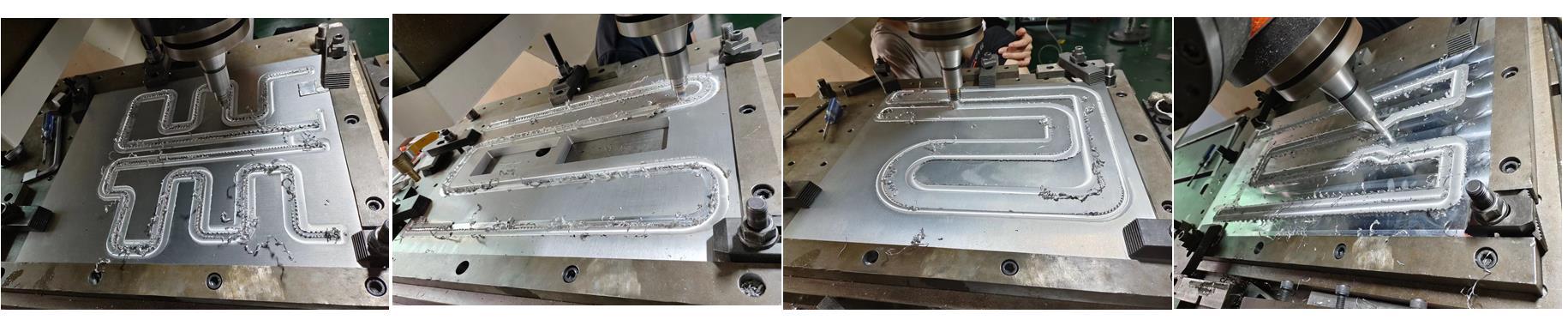

2) The CNC machining cover or base;

3) The deep drilling channels body with a CNC machining cover;

4) The extrusion channel body with a CNC machining Welding plug.

5) The die casting housing base with a CNC amchining cover,

Varieties of flow channels with different structure for the cold plate design can meet your custom liquid cooling demand!

Friction Stir Welding (FSW) is applied in air cooling solutions:Compared with the application of friction stir welding in cold plates, the application of (friction stir welding) FSW process in air-cooled heat sinks appears to be much simpler.

The main manifestation is that when the structure of the heat sink cannot be directly manufactured using a single process, friction welding can be employed to address the parts of the structure that do not meet the heat dissipation requirements.

For excamples:

1,FSW applied for the extrusion heat sink :When encountering situations where very large-sized aluminum extruded heat sinks cannot be produced using the extrusion tooling, We can combine two aluminum heat sinks by means of friction welding to form a single large-sized extrusion heat sink.

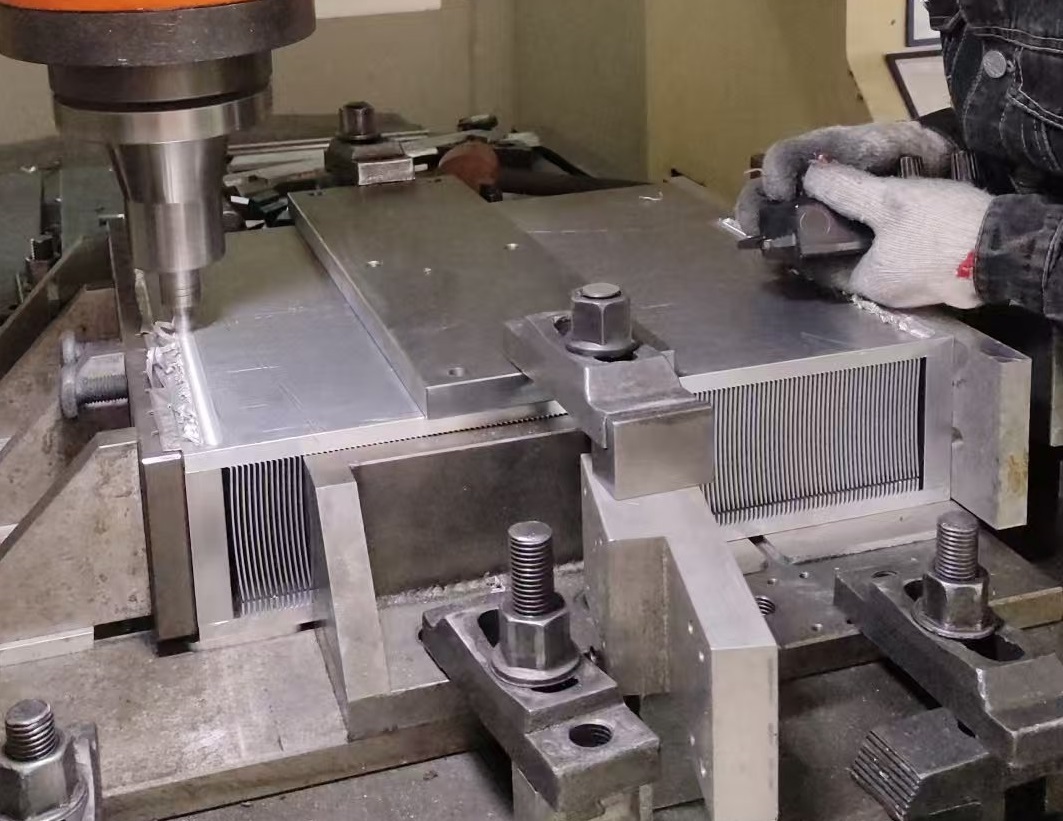

2,The FSW process applied for the skived heat sink:The structural feature of the skived heat sink is that all the fins are uniform. When there is a requirement for inconsistent structure and fins thickness in the design of the skived heat sink,We can first use CNC machining to create the missing parts, and then use friction stir welding to attach the required structure.

3,The FSW process changing the design which the bonded fin heat sink can't meet the cooling requirement:Usually, heat sinks with two sides having substrates are typically achieved through adhesive bonding.However, at present, we can use friction welding to combine two skived heat sinks or extruded heat sinks into a heat sink with two base plates on both sides.

Friction welding technology and techniques can provide us with more design references for our cooling solutions, and offer more possibilities for the heat dissipation schemes.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?