Cold plates with a deep drilling solution for high-power power supply liquid cooling

As the core component of power conversion and control, industrial power supply is widely used in industries and fields with high requirements for power stability and reliability. High-frequency power modules have higher requirements for efficient heat dissipation. The liquid cooling plate of the liquid cooling solution provides a stable heat dissipation effect for high-power power supplies.

Next, let's see which fields will use high-power power supplies?

1. Manufacturing: high-power fiber laser power supply, PLC servo drive power supply;

2. Energy and infrastructure: substation DC power supply, photovoltaic inverter power supply, energy storage system PCS power supply;

3. Electronics, semiconductors: RF power supply, semiconductor packaging equipment heating power supply;

4. Medical equipment: CT high-voltage power supply, shadowless lamp DC power supply;

5. Aerospace, communication: array control power supply, switching power supply module, backup UPS power supply;

6. Data center: server power supply, energy storage power supply; AI server high power density promotes UPS power supply to modular and intelligent upgrade;

7. Emerging fields: on-board OBC power supply of new energy vehicles, liquid cooling power supply of super charging stations, and the hydrogen production power supply market grows with the expansion of green hydrogen projects. IGBT power supply increases power in low-load scenarios and converts power supply applications.

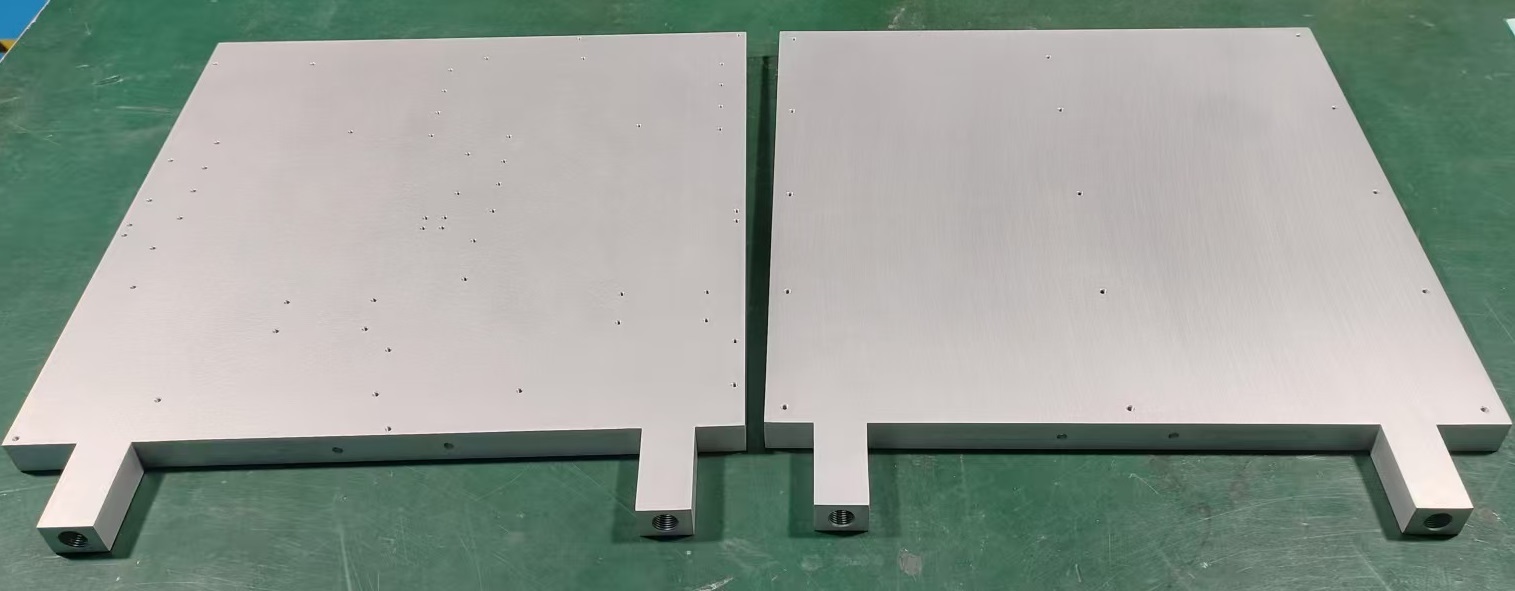

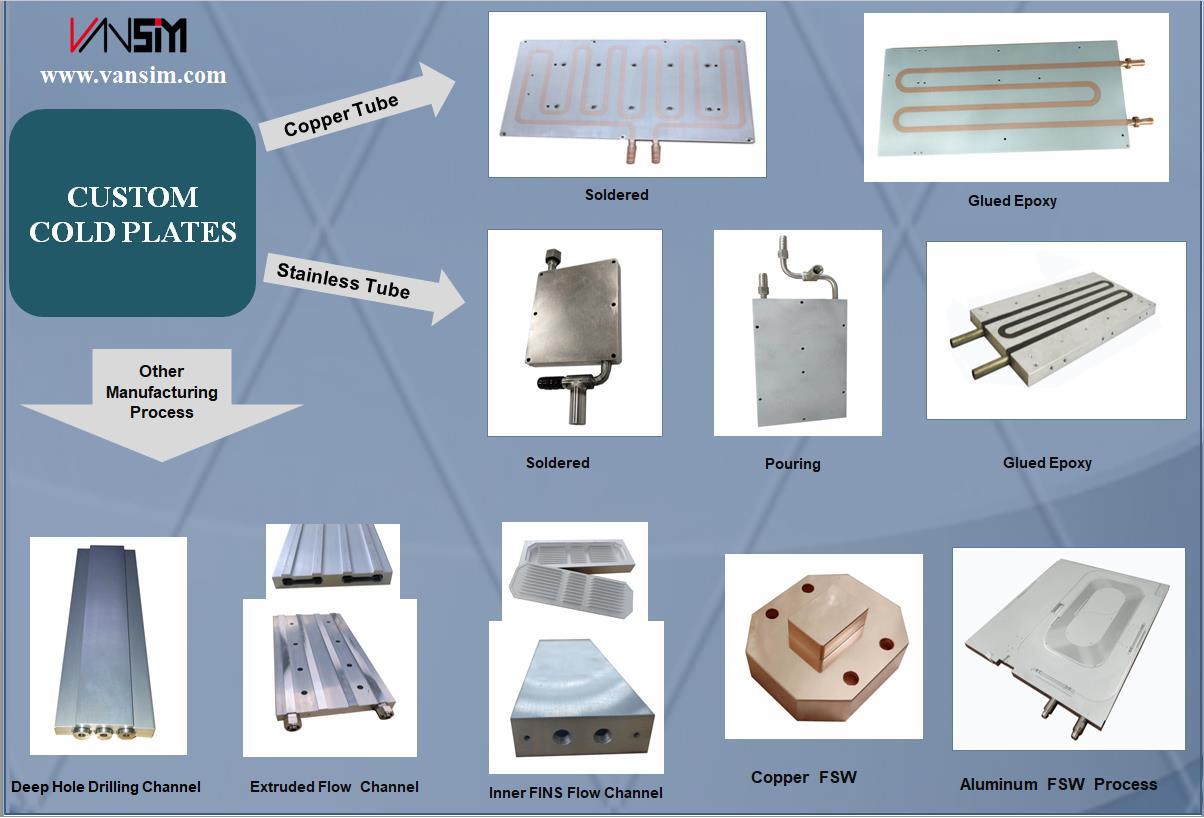

If you need liquid cooling solutions or liquid cooling plates when manufacturing industrial power supplies for these industries, Vansim can provide you with various liquid cooling solutions and cooling plates with different processes. The following is a deep hole processing liquid cooling plate solution provided by our company for high-power power supplies.

What is the processing process of deep hole drilling water cooling plate?

1. Material selection: AL6061 or AL6063 materials are usually selected;

2. Preliminary size processing is completed through CNC;

3. Through deep hole drilling process, the direct current channel processing of the cold plate is completed;

4. Through CNC and friction welding processing, the flow channel circulation of the liquid cooling plate is completed;

5. Finally, notify CNC processing to complete the final finished product size and hole position processing;

6. Surface treatment: Anode or passivation and other surface treatment methods are usually used to increase corrosion resistance and oxidation resistance;

7. Leakage test: Leakage test is the most indispensable link as a water cooling plate and the most basic requirement.

|

PREVIOUS:

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?