what does Vansim's capabilities manufacturing for the skiving heat sink?

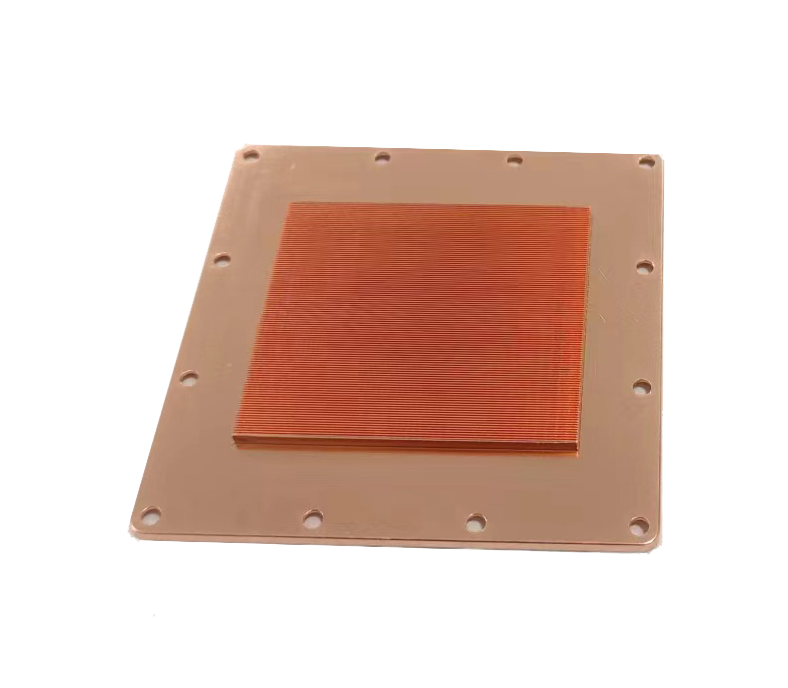

Vansim has years of experience in skiving heat sink processing, which can provide stable - quality and efficient - output heat sink customization services.

Does Vansim offer customization services for skiving heat sinks?

|  |

|  |

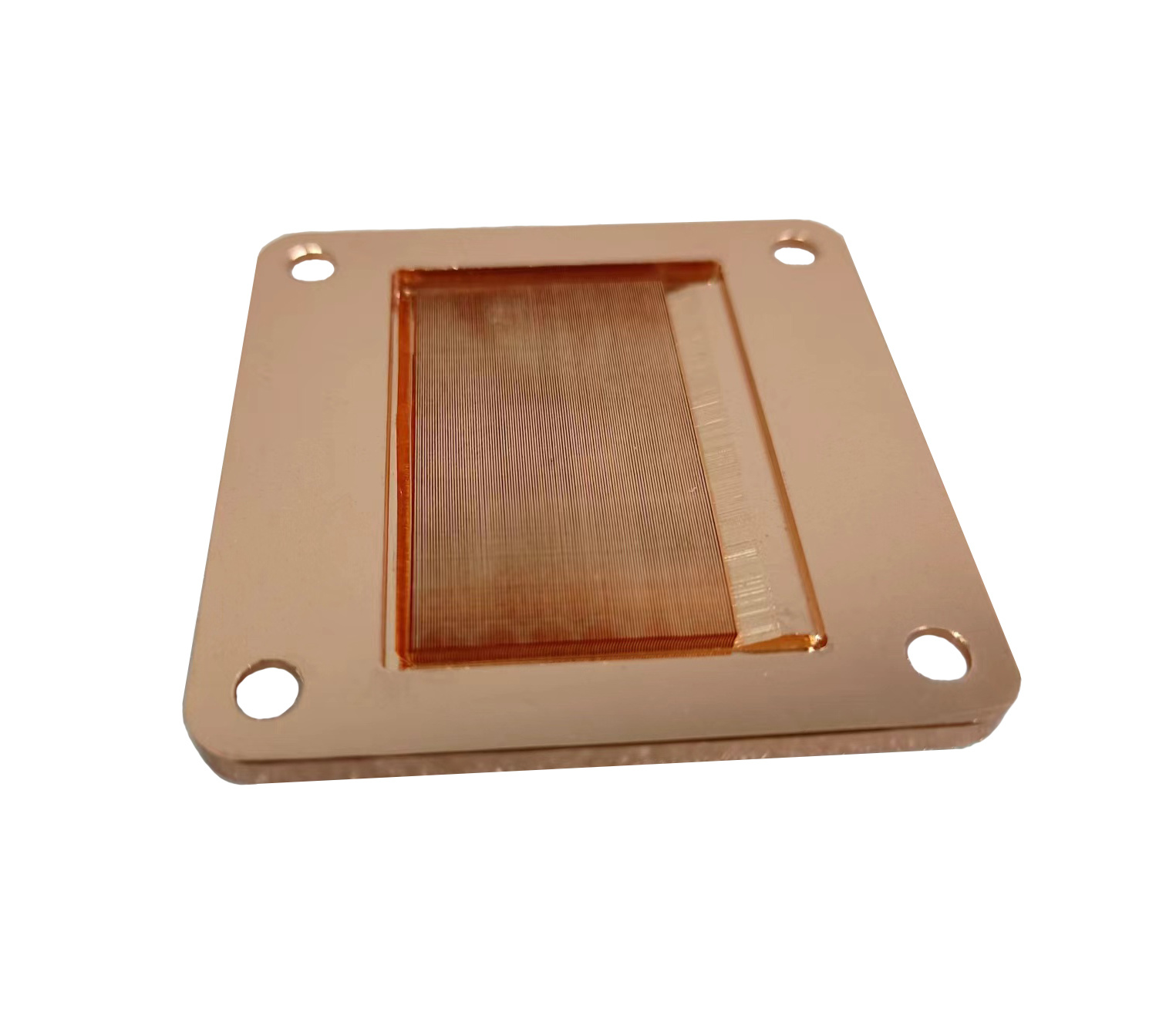

- Design suggestions: With years of experience in skiving heat sink processing, Vansim can provide customers with design suggestions for product design, material selection, and process technology. For example, it can offer advice on choosing aluminum or copper materials according to different application scenarios to meet customers' heat dissipation requirements. The company is also willing to provide in - plant manufacturing suggestions for customers' designs and carry out a series of customized processing to realize the characteristics of customers' products.

- Parameter determination: Vansim is well - versed in the process parameters of skiving heat sinks.

- The aluminum skiving fin process parameters :

- Skiving base thickness of 1 - 30 mm,

- Skiving fin width of less than 700 mm,

- Skiving fin height of less than 150 mm,

- Skiving fin thickness of 0.05 - 2.0 mm, a fin gap of 0.08 - 6.5 mm,

- A skiving fin heat sink length of 1200 mm.

- The copper skiving fin process parameters are similar to those of aluminum. It can determine the most suitable parameter values based on customers' customized requirements to ensure the performance of heat sinks.

- Vansim's Skiving fin Process technology support:

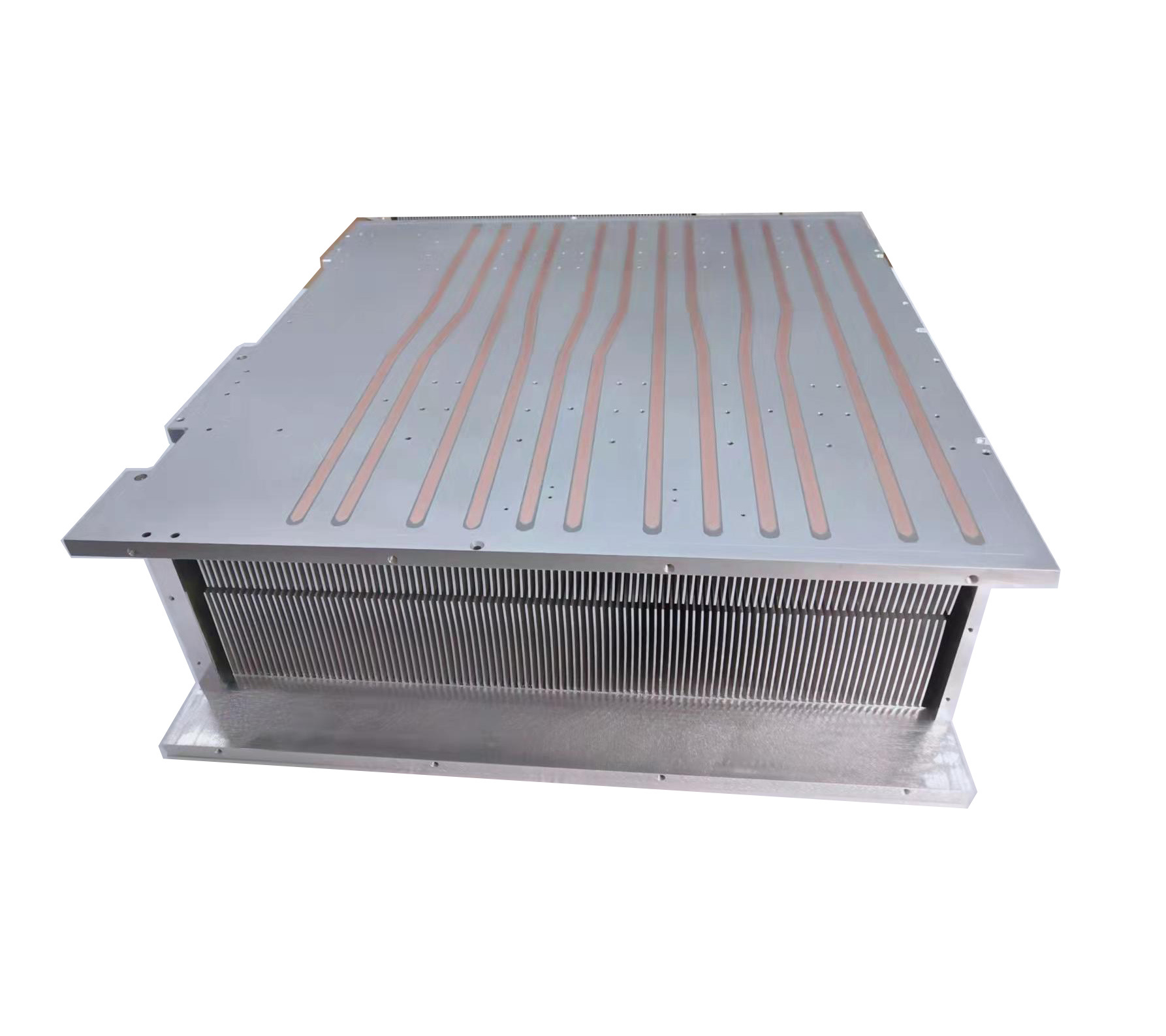

- Skiving fin process: Vansim uses high - precision cutting technology to cut long strips of plate into relatively straight sheets at a certain angle using a special tool through mechanical action. Repeated cutting forms a uniformly ordered gap heat - dissipation fin structure, and then through subsequent cutting, machining, surface treatment, and other methods, it is processed into a radiator. This process can obtain heat - dissipation teeth with higher teeth and smaller gaps, resulting in a larger heat - dissipation area to improve the heat - dissipation effect. Moreover, the heat - dissipation teeth and the base plate are integrally processed and formed without interface thermal resistance.

- CNC and friction stir welding: Due to the process characteristics of skiving heat sinks, if the heat - dissipation design requires adding thicker columns or fins in the middle of the teeth, the skiving process itself cannot achieve this. Vansim uses CNC processing to clear the position where the column needs to be added and then uses friction stir welding to integrate the thick column with the skiving heat sink to achieve the production of the overall heat - dissipation design.

TAG:

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?