As a manufacturer of skived fins heat sink, How to choose the material for your skived fin design?

The most commonly used materials for skived heat sinks are aluminum alloys and copper, with aluminum being the dominant choice for most applications. Below is a detailed breakdown of their usage, advantages, and typical applications:

As a manufacturer of skiving fins heat sink, How to choose the material for your skiving fin design?

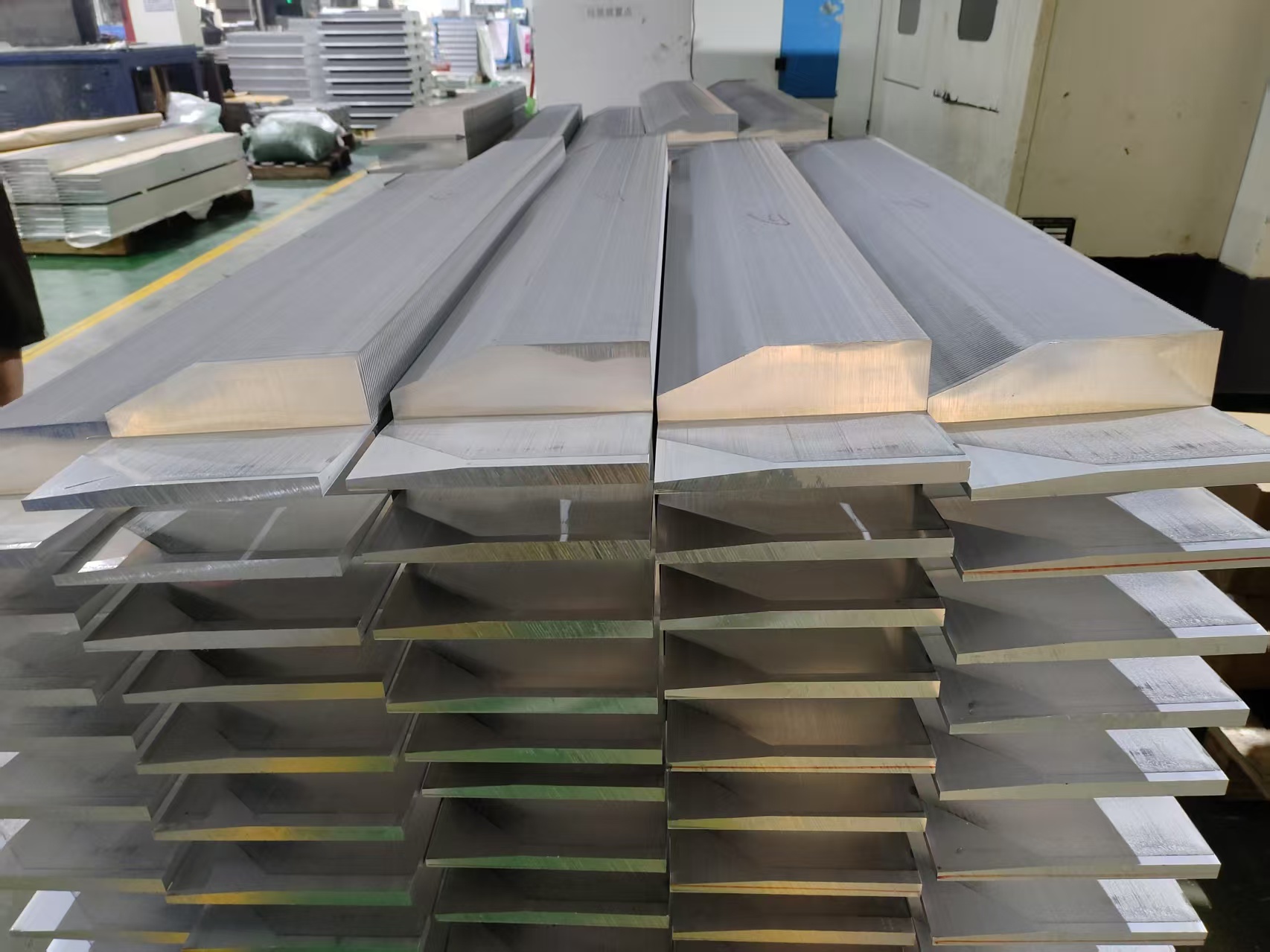

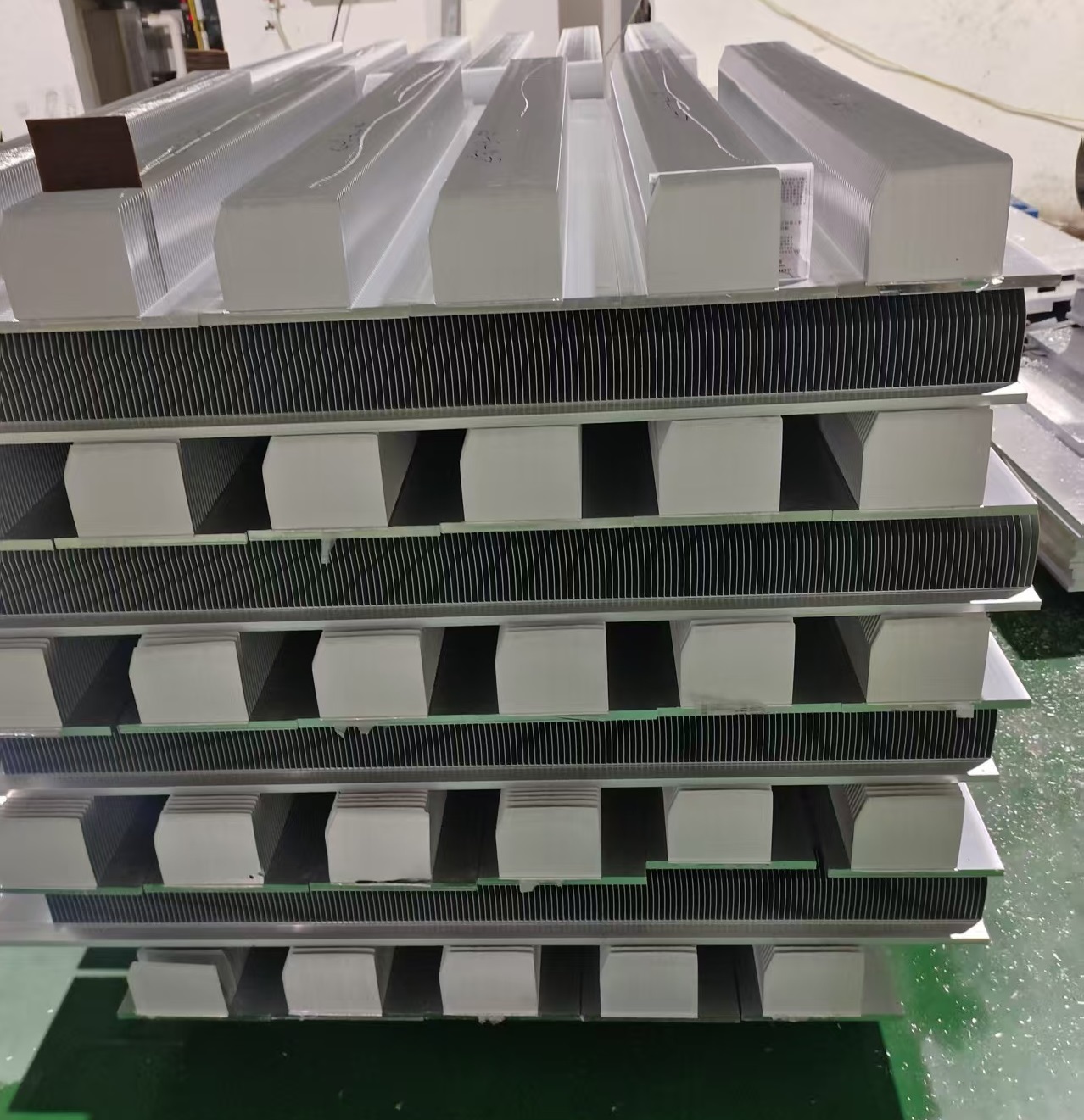

1. Aluminum Alloys

- Lightweight: Low density (2.7 g/cm³), ideal for portable or weight-sensitive devices.

- Cost-Effective: Lower material and manufacturing costs compared to copper.

- Good Processability: High ductility allows for thin, densely packed fins via skiving (a machining process where thin fins are "peeled" from a solid block).

- Corrosion Resistance: Naturally forms a protective oxide layer, reducing maintenance needs.

Common Aluminum Alloys for Skived Heat Sinks

|  |

- 6063 Aluminum:

- Widely used for skived fins due to balanced strength, ductility, and thermal conductivity (~150–200 W/m·K).

- Example: Heat sinks for laptops, desktop PCs, LED lighting, and consumer electronics.

- When using this grade of material, extruded materials are usually required;

- The advantage lies in that the extrusion profile can provide different shaped heat sink base designs for the skiving fin heat sink.

- 1100 Pure Aluminum:

- Higher thermal conductivity (~205 W/m·K) but softer, making it suitable for simple fin designs or low-stress applications.

Applications

- Consumer Electronics: Laptops, tablets, gaming consoles (e.g., Xbox/PlayStation heatsinks).

- LED Lighting: High-volume, cost-sensitive fixtures (e.g., streetlights, indoor LED panels).

- Automotive: Engine control units (ECUs), electric vehicle (EV) battery cooling systems (due to weight restrictions).

- General Cooling: Fan-cooled heat sinks in power supplies, routers, and industrial controls.

- New energy: High power embedded heat pipes heat sinks for inverter cooling, Charge stations.

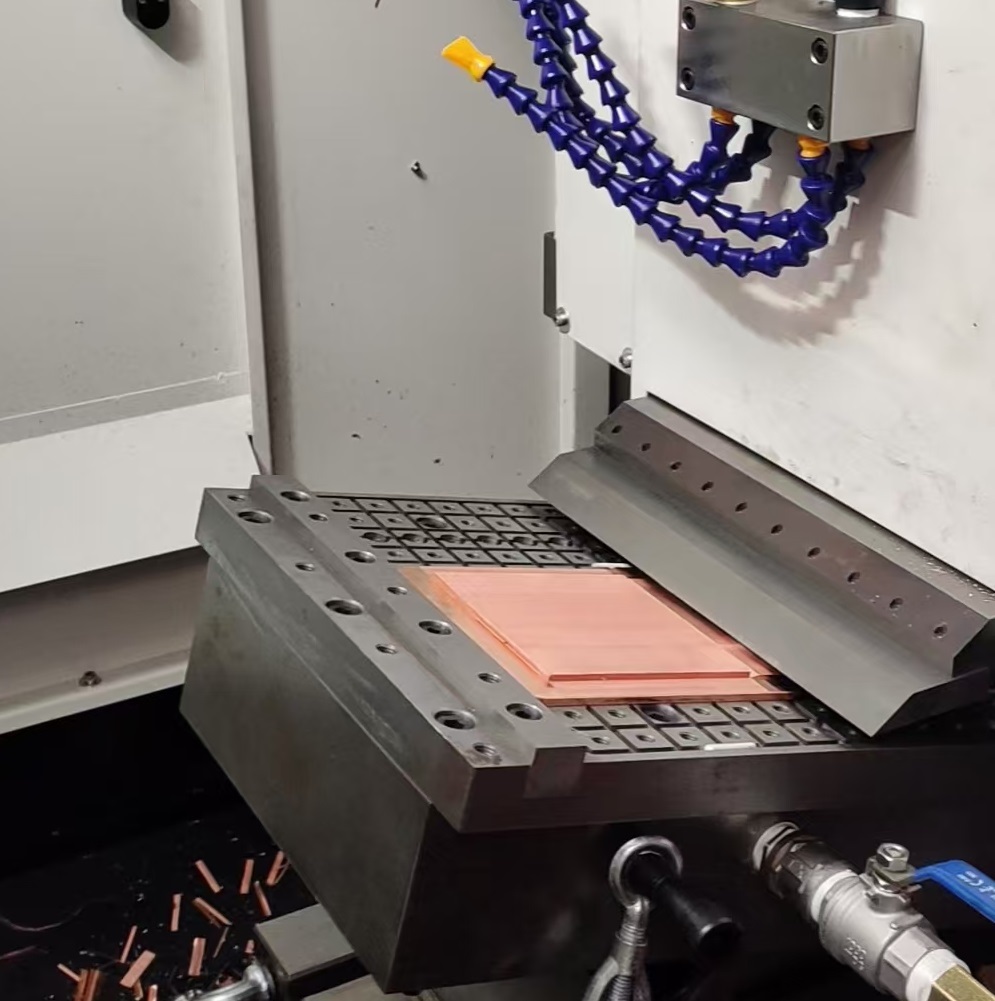

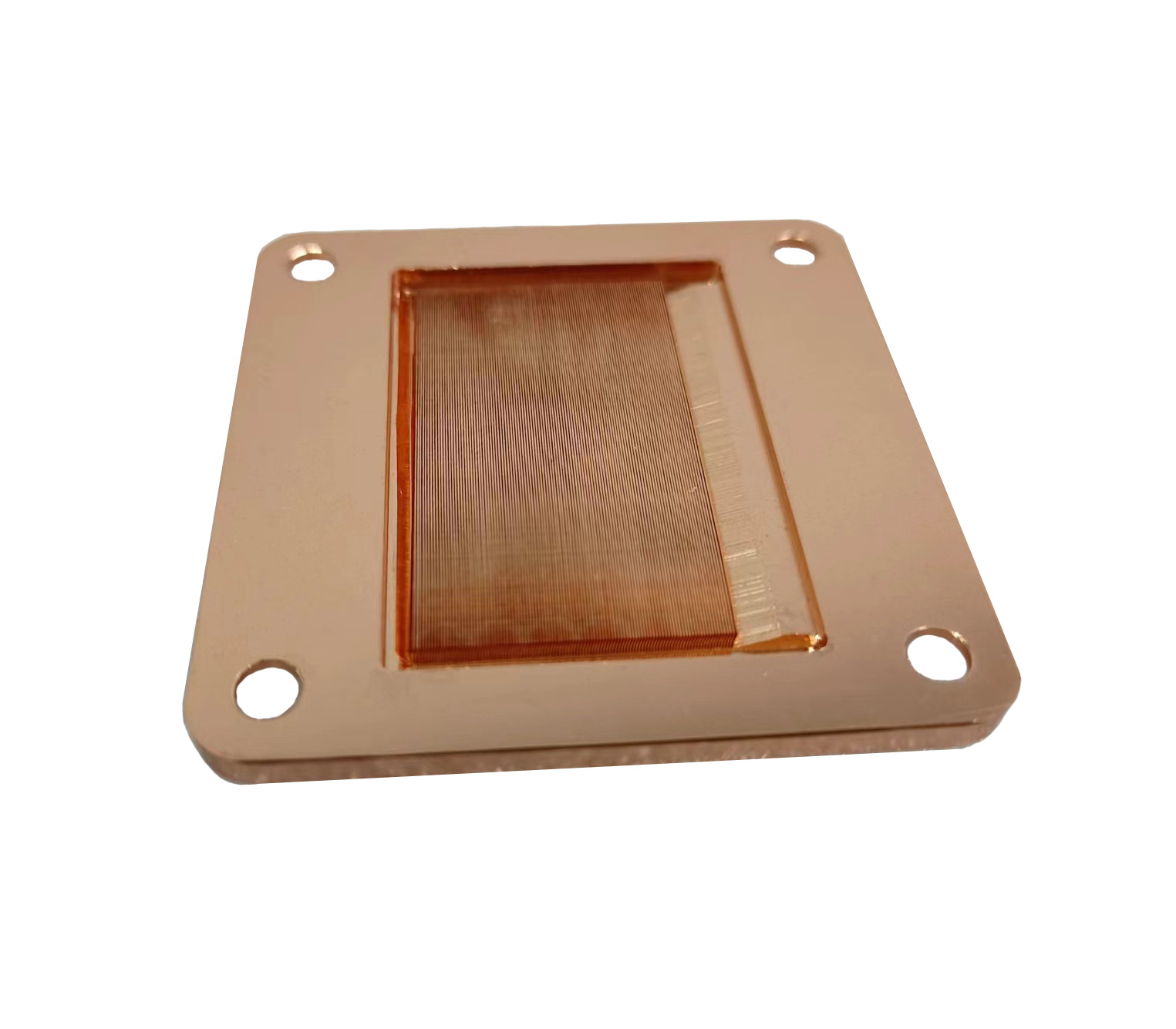

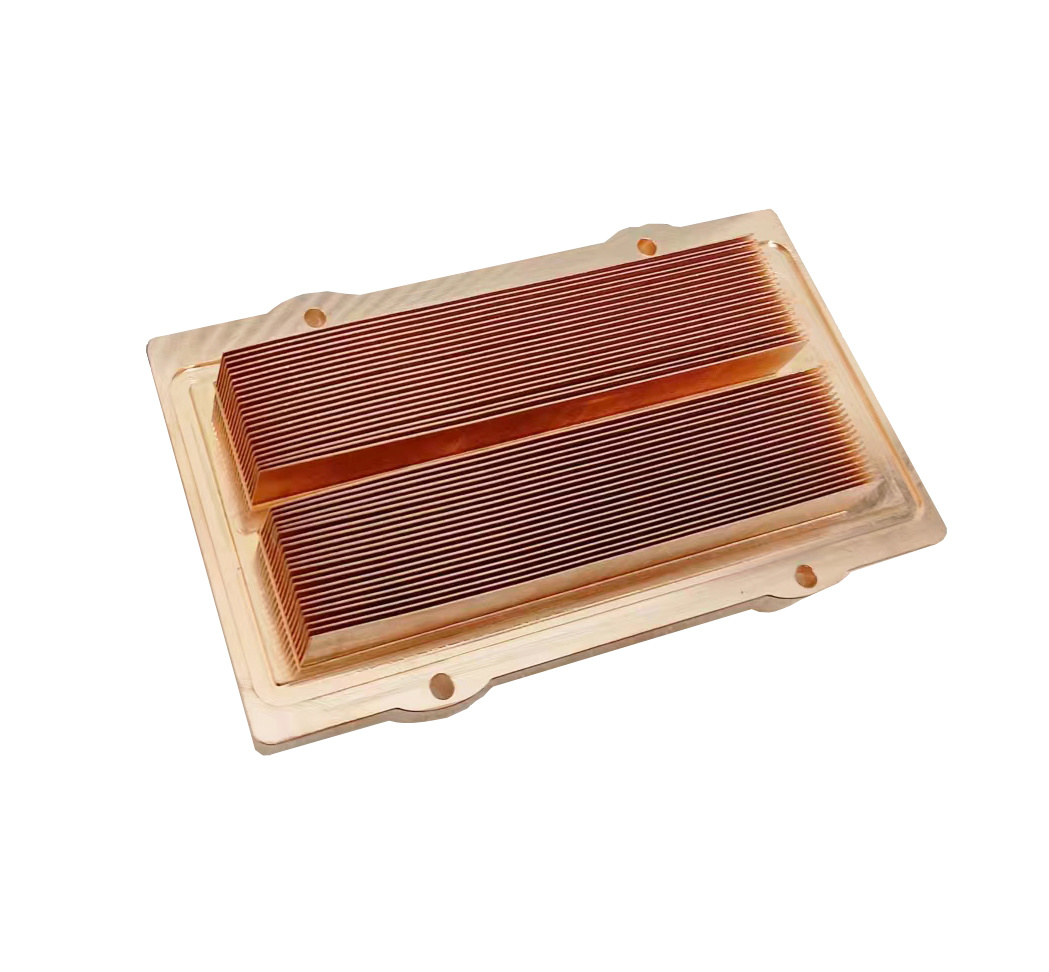

2. Copper material for skiving fin

- Superior Thermal Conductivity: ~401 W/m·K, making it ideal for rapid heat transfer in high-power applications.

- High Thermal Mass: Absorbs and stores heat effectively, suitable for short-duration high-heat spikes.

Types of Copper Used

- Oxygen-Free High-Conductivity (OFHC) Copper( Cu1100, CU1020):

- Purest form (~99.95% copper), maximizes thermal conductivity.

- Used in premium heat sinks or critical components (e.g., CPU heat spreaders in servers).

- Brass (Copper-Zinc Alloy):

- Rarely used for skived fins due to lower conductivity (~100 W/m·K), but occasionally for decorative or specialized purposes.

Applications

- High-Power Electronics: Data center servers cooling, GPU accelerators (e.g., NVIDIA A100), and industrial power amplifiers.

- Aerospace/Medical Devices: Where reliability and thermal performance outweigh cost (e.g., avionics, laser systems).

- Hybrid Designs: Copper bases with aluminum fins (e.g., gaming laptop heatsinks) to balance conductivity and cost.

|  |

Summary

- Aluminum alloys are the workhorse for skived heat sinks due to their optimal balance of cost, weight, and thermal performance in most applications.

- Copper is reserved for high-stakes, high-power scenarios where superior heat transfer justifies the higher cost and weight.

TAG:

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?