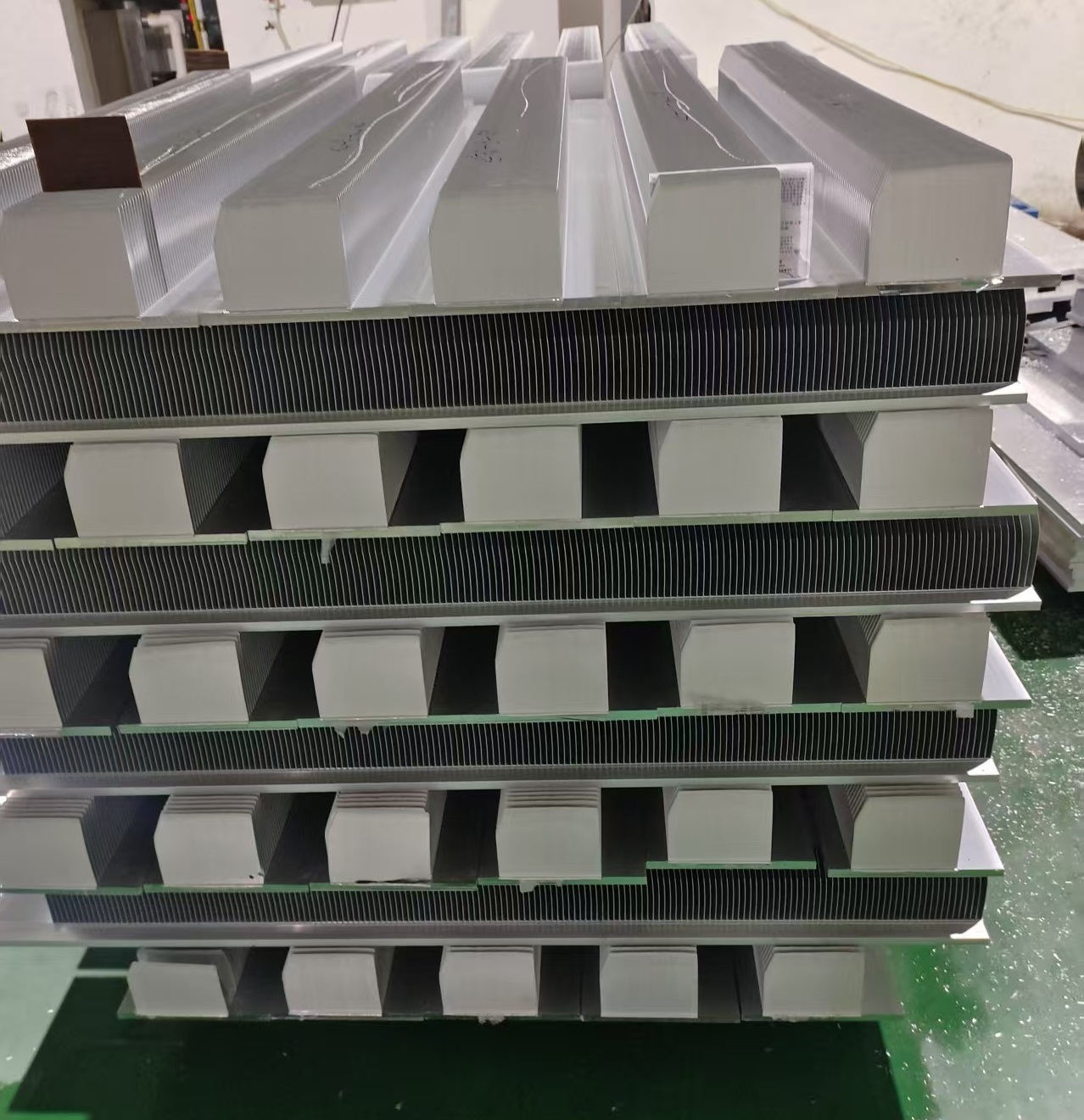

The extruded material formation an angle heat sink by the skived fin process

A method to reduce heat sink processing costs by leveraging the skiving fin process for one-time integrated inclined angle heat sink formation.

Technical Principle

Key Features:

- One-Time Formation: The base and inclined fins are machined simultaneously, reducing process complexity.

- Precision Machining: Computer numerical control (CNC) ensures accurate control of fin angle, height, and spacing.

- Material Efficiency: Minimizes material waste compared to traditional fin-stacking or bonding methods.

Implementation Steps and Considerations

1. Extrude Material Selection for skived heat sink

- Use extruded materials with good machinability (e.g., 6063,1060 aluminum alloy for cost-effectiveness or copper for high thermal conductivity).

2. Design Optimization

- Inclined Angle Design:

- Optimize the fin angle based on airflow direction to enhance heat dissipation efficiency.

- Use simulation tools (e.g., ANSYS, COMSOL) to validate heat dissipation performance before prototyping.

- Fin Geometry:

- Balance fin thickness (Alminum skiving fins usually be 0.1–2.0 mm) and height (10–150 mm) to avoid machining instability (e.g., fin bending or breakage, or deformation).

3. Machining Parameters

- Tooling: Use high-hardness carbide or diamond-coated cutting tools to withstand long-term machining of metallic materials.

- Cutting Speed and Feed Rate:

- For aluminum: Cutting speed = 80–150 m/min, feed rate = 0.05–0.2 mm/tooth.

- For copper: Cutting speed = 30–80 m/min, feed rate = 0.03–0.1 mm/tooth.

- Cooling Lubrication: Apply water-based coolants or minimum quantity lubrication (MQL) to reduce tool wear and improve surface finish.

4. Process Integration

- Integrate the skiving fin machine with in-line quality inspection (e.g., vision systems for fin angle and dimension checks) to reduce rework.

- Avoid secondary processes (e.g., deburring) by optimizing cutting parameters to achieve smooth fin edges.

Application Scenarios

- Electronics Cooling: Heat sinks for CPUs, GPUs, and power modules.

- Automotive: Battery thermal management systems (BTMS) cooling and motor controllers air cooling.

- Industrial Equipment: Inverters cooling, server racks cooling, and LED lighting cooling.

Case Study (Theoretical Example)

- Traditional cost: $5.00/unit (extrusion + 10 fins welded + surface treatment).

- Skiving fin process: $3.50/unit (one-step machining + anodizing), with a 20% improvement in heat dissipation efficiency due to the optimized 45° inclined fins.

TAG:

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?