// ABOUT US

Company Profile

Vansim is a total thermal solution design and production company, providing customers with the best cooling solutions for different needs.It is also most cost-effective solution

Vansim (Dongguan) Hardware Products Co., Ltd locates in Hengli Town, Dongguan City. We are a professional manufacturer combines design, producing and sales for high-power heatsinks and different Precision parts.

Our products include water block, liquid cold plate, heat pipe heat sink, skived heatsink, extruded heatsink, soldered heatsink, bonded heatsink , aluminum structural parts, CNC machined parts, Precision CNC machining parts .

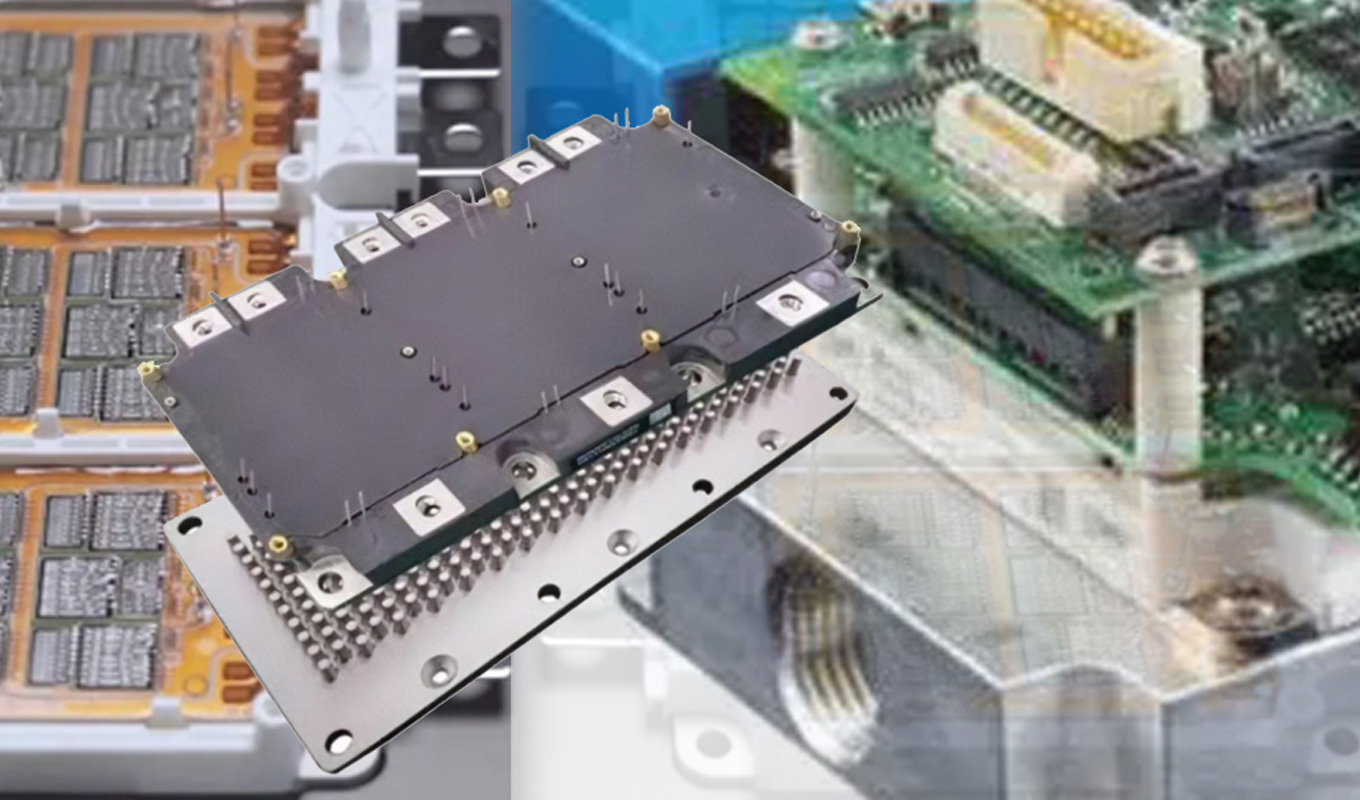

All these products are widely used on data center servers, high power supply, EV, energy storage, invertors ,IGBT modules, batteries, laser, smart driving, medical facilities, New energy management,LED light, semiconductor cooling etc.

We are open to OEM service as well as design & produce precision parts to meet customer’s requirements.

Vansim is a young company in thermal and precision industry, but we have professional team with rich experience, advanced producing equipment and precision test facilities. Keep pursuing high precise manufacturing and good quality are our lifelong target.

// PRODUCTS

Choose Our Products

Vansim excel in the comprehensive process of high-power heat sinks and liquid cooling plates products, including careful design, advanced development, rigorous testing, precise optimization, and customized manufacturing.

Vansim as a manufacturer, Has a complete development process. We can customize and process various aluminum alloy precision machining parts, heat sinks, liquid cooling plates and other types of products according to customer drawings. Customers can also make demands and entrust our company to carry out thermal design, manufacturing, verification and other work. Either way can meet customer requirements.

// SUPPORT

VANSIM Manufacturing Support

We have advanced production equipment and efficient production processes, which can meet the needs of large-scale and high-quality production in the shortest time. At the same time, we have superb production technology and an experienced technical team to provide customers with stable and reliable product output.

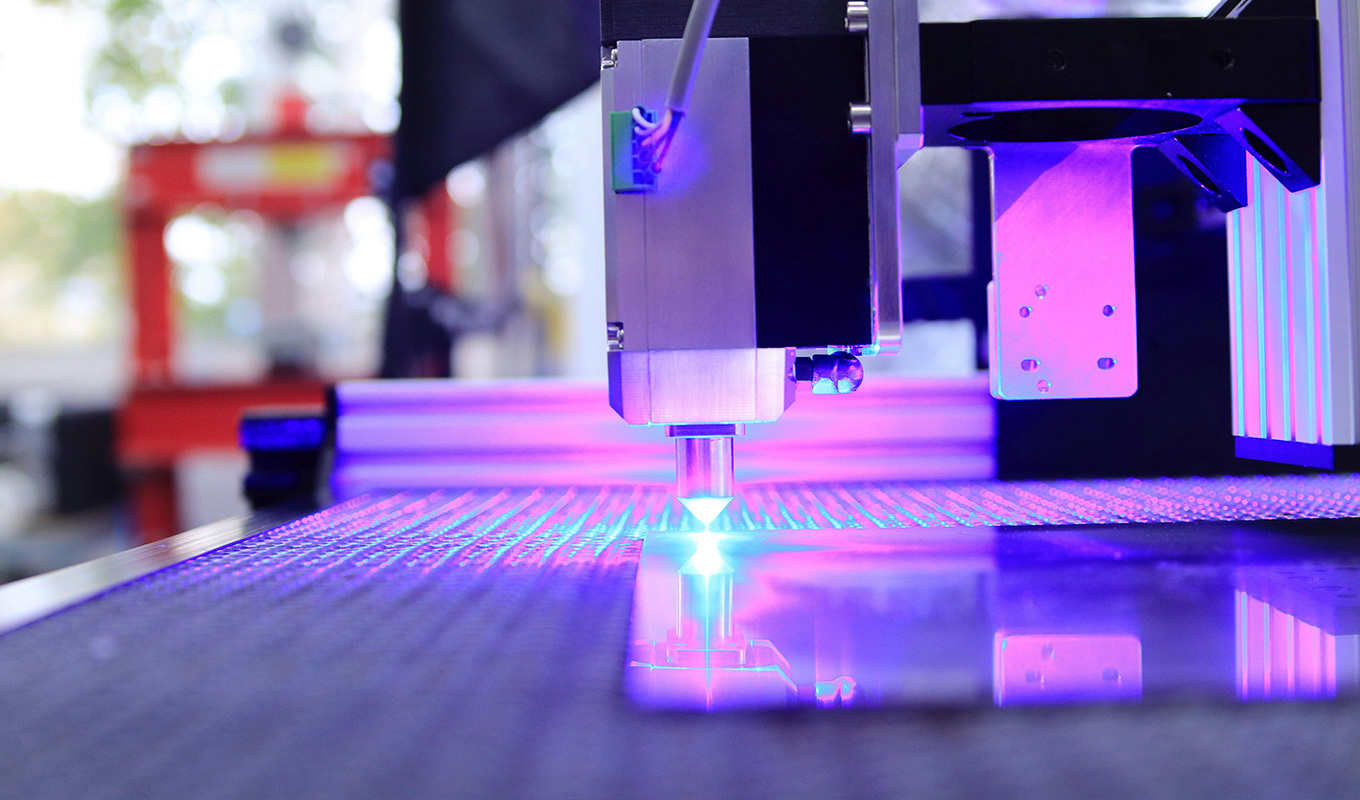

●·· Cutting

●·· Friction Stir Welding

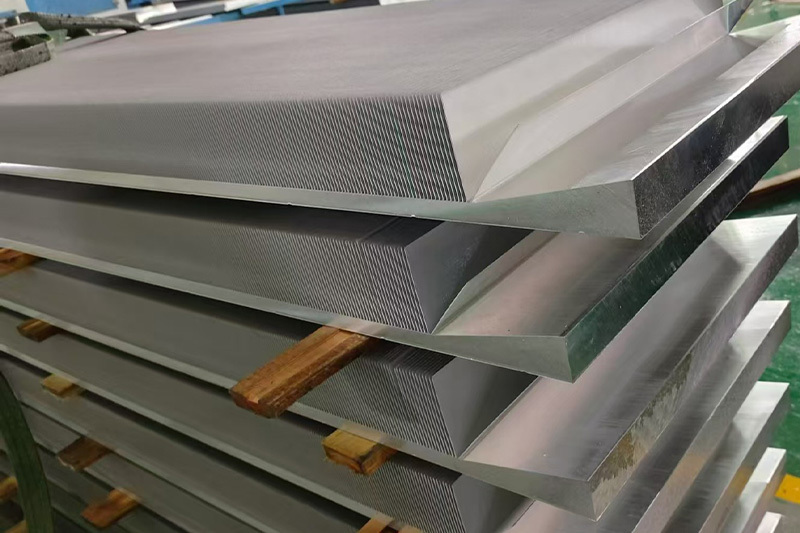

●·· Skived fin Machining

●·· Soldering

●·· Brazing

●·· CNC Machining

●·· Bonding

// SOLUTION

Thermal Simulation

The purpose of thermal design is to control the temperature of all electronic components inside the product so that they do not exceed the maximum temperature specified by standards and specifications under the working environment conditions.

// TEST

Product Verification Testing

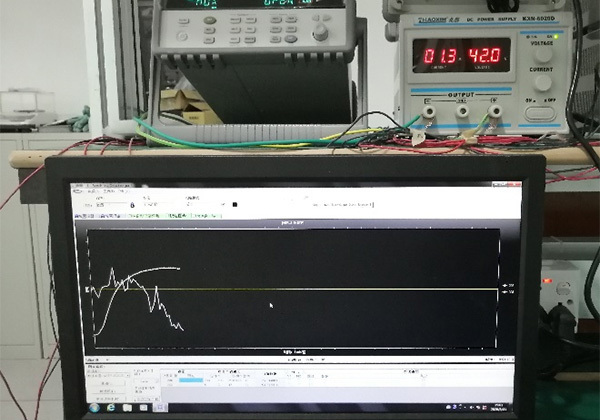

Thermal testing is an essential part of product heat dissipation design. Thermal testing is an important part of ensuring product heat dissipation performance. The functions of thermal testing mainly include the following four aspects:

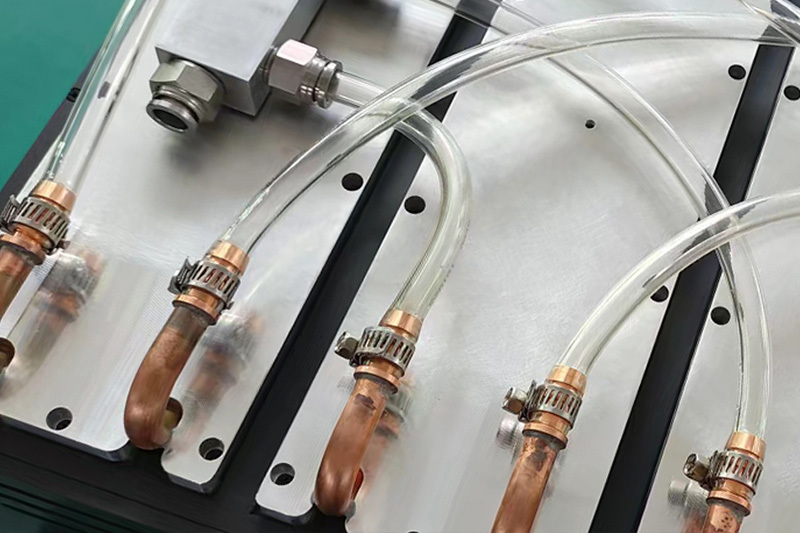

The liquid cooling plate is an important part of the night cooling system. Once a leak occurs, it will cause a serious accident. The night cooling plate must be 100% airtight tested before shipment to ensure the reliability of the night cooling plate in use.

Flow resistance is an important indicator of liquid cooling system and liquid cooling plate. In order to make the cooling system of the equipment work close to the theoretical design conditions, the design must ensure that the flow resistance of the liquid cooling system matches the flow resistance distribution value of the environmental control system design. The intersection of the flow resistance characteristic curve of the flow channel and the characteristic curve of the pump is the working point of the pump. The working point can be used to judge the efficiency of the water pump and whether the flow channel or pump matches the liquid cooling system.

// APPLICATIONS

Diverse Industry Solutions

// BLOG

News & Media

Why the Aluminum Extrusion Heat Sink Remains a Cornerstone of Modern Thermal Management

Feb 23,2026

In an era dominated by discussions of advanced liquid cooling and vapor chambers, a fundamental and versatile technology continues to power the thermal management of countless electronic devices: the Aluminum Extrusion Heat Sink.

Feb 16,2026

The rapid electrification of vehicles and the constant demand for weight reduction in aerospace have catalyzed a major innovation in thermal control systems: the ultra-lightweight Embedded Heat Pipe Heat Sink.

Embedded Heat Pipe Heat Sink Revolutionizes High-Performance Computing

Feb 09,2026

In a significant leap for electronics cooling technology, a new generation of Embedded Heat Pipe Heat Sink solutions is setting a new standard for thermal management in compact, high-power devices. As processors in servers, gaming consoles, and workstations push performance boundaries,