Liquid cooling plate pressure simulation case

1. Simulation purpose

Apply simulation software to analyze the mechanical performance of liquid cooled plates, and conduct a detailed analysis of the deformation and stress distribution of liquid cooled plates under internal pressure load conditions, in order to evaluate the rationality of the structural design of liquid cooled plates and the friction welding span of the upper cover plate, and provide theoretical basis for the optimization design of liquid cooled plate structures.

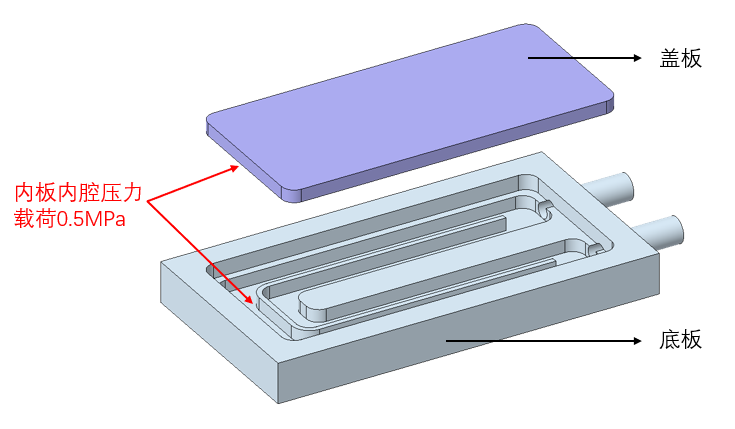

2. Enter information

Application conditions

Internal pressure load: 0.5MPa

Liquid cooled plate material: cover plate AL6061/bottom plate AL6061

| Material name | Density g/cm³ | Tensile Strength Mpa | Yield Strength Mpa | Elastic Model GPa | Poisson's ratio |

| AL6061 | 2.7 | 310 | 276 | 69 | 0.33 |

3. Simulation model

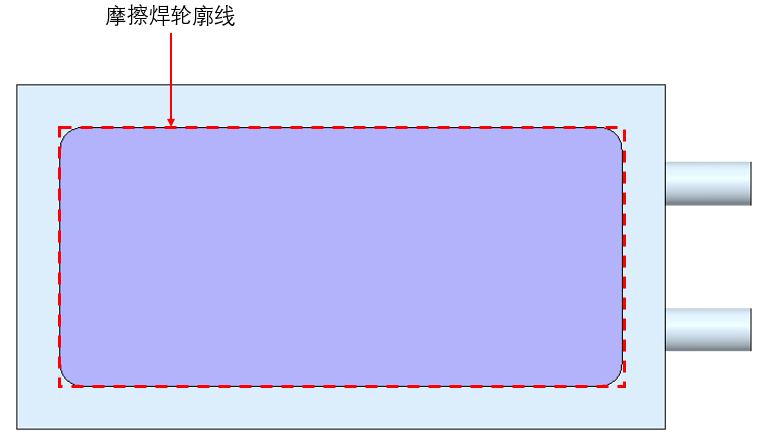

Analysis model description

4. Scheme and simulation

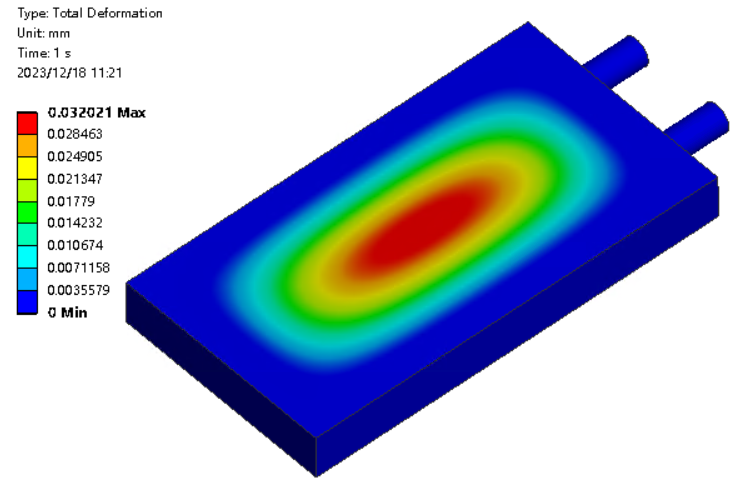

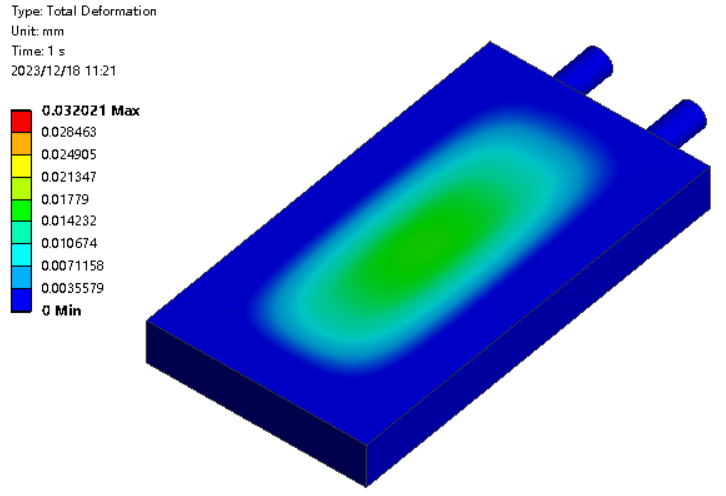

Cloud map of deformation distribution of liquid cooling plate

The maximum deformation of the liquid cooled plate under an internal pressure load of 0.5MPa is 0.032mm

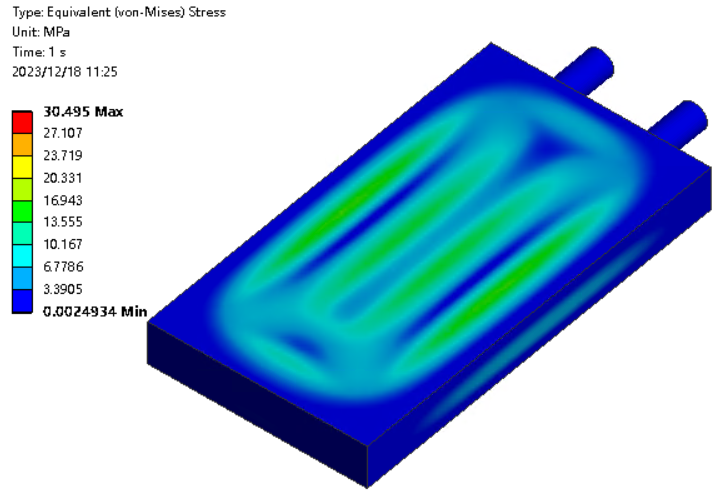

Stress distribution cloud map of liquid cooled plate

The maximum equivalent stress of the liquid cooled plate under an internal pressure load of 0.5 MPa is 30.5 MPa

5. Conclusion

Summary of simulation data

| Serial Number | Scheme | Liquid cooled plate material | Internal pressure load | Maximum deformation variable | Maximum equivalent stress |

| 1 | Original scheme | AL6061 | 0.5MPa | 0.032mm | 30.5MPa |

Conclusion&Suggestions

According to simulation analysis, the maximum deformation of the liquid cooled plate under a pressure load of 0.5MPa is 0.032mm, and the maximum equivalent stress is 30.5MPa, which is much lower than the yield strength of AL6061 material at 276MPa. The product deformation is small and elastic, within a safe range; The current design of liquid cooled plate structure and friction welding span scheme can ensure the safe use of liquid cooled plates.

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?