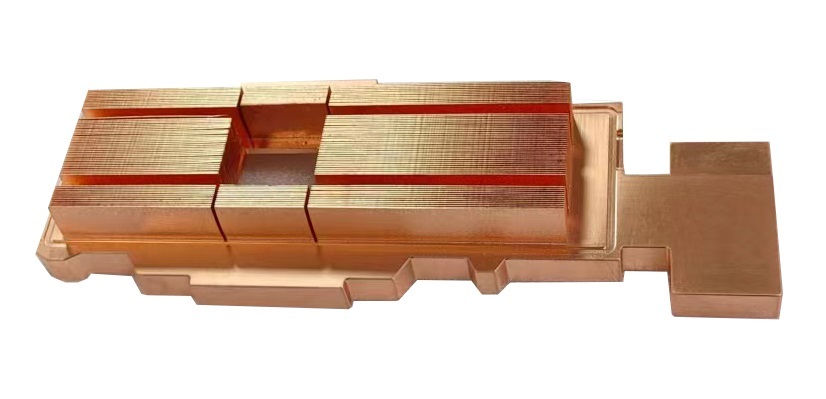

The Significance and Advantages of Split-Flow Technology in All-Metal Microchannel Cold Plates

In the realm of thermal management for high-performance electronics, all-metal microchannel cold plates have emerged as a crucial solution to dissipate the ever-increasing heat generated by advanced components, Here we delves into the necessity of split-flow technology and contrasts the advantages of cold plates with and without this innovative feature.

In high-power applications such as data center servers, AI accelerators, and high-performance GPUs, hotspots are common occurrences. These hotspots can cause localized overheating, leading to reduced performance and potential component failure. Split-flow technology is specifically engineered to the liquid cooling cold plate. It ensures that the coolant first reaches the areas of highest heat generation, effectively preventing thermal runaway and maintaining optimal operating temperatures.

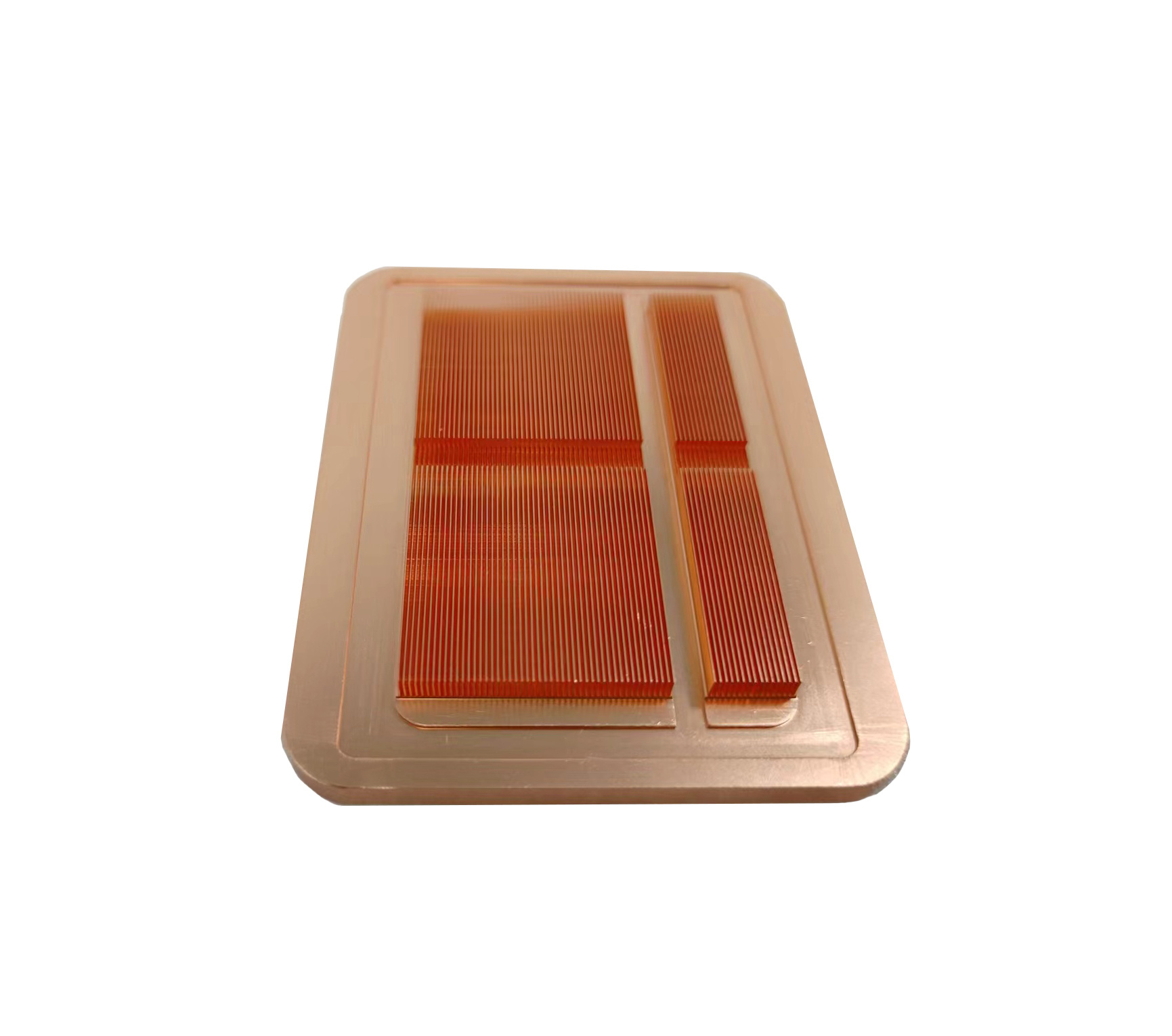

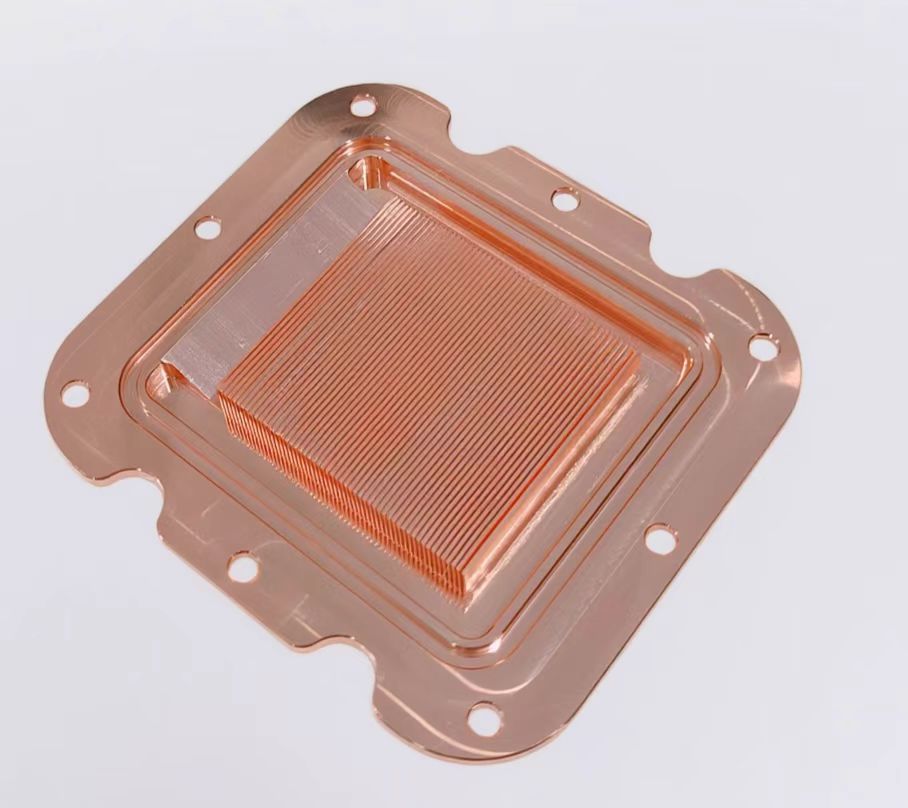

Advantages of Cold Plates with Split-Flow Technology

1,The unique design of the Split Flow Cold Plate distributes the coolant more evenly across the microchannels, more efficiently transferring heat from electronic components to the coolant, thereby reducing operating temperatures and improving device performance.

2,The flow splitting technique can reduce flow resistance, effectively halving the coolant flow path within the microchannel. The reduction in flow path length not only reduces pressure drop, but also allows for more efficient use of the coolant pump. The cooling system can use smaller, more energy-efficient pumps.

3,The flow splitting technique enables precise hot spot cooling by directing coolant flow to areas of highest heat flux. This cooling method allows the hottest parts of electronic components to be cooled first, preventing local overheating and improving the overall temperature distribution of the entire device.

In applications such as artificial intelligence chips, some processing cores may generate more heat than others, so

shunt cold plates can be designed with priority.

|  |

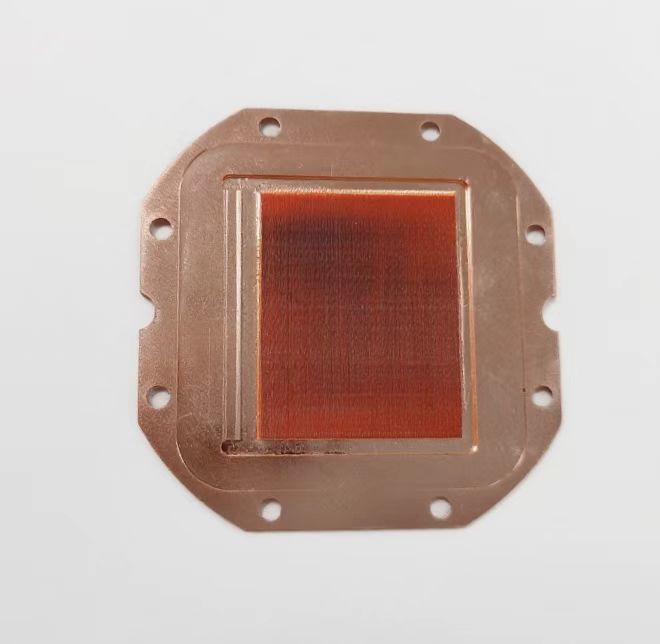

Advantages of Cold Plates without Split-Flow Technology

1,Cold plates without shunt technology typically have a basic end-to-end microchannel layout, providing a simpler design and manufacturing process. The straightforward structure of these cold plates is easier to manufacture and requires fewer machining operations.

This simplicity can reduce production costs in applications where cost is the primary consideration and thermal requirements are not demanding, making it a more viable option for large-scale production.

|  |

In summary, the choice between cold plates vs. non-split flow technology depends on the specific requirements of the application. For high-power, high-performance electronics where thermal performance and hotspot management are critical, split flow technology offers a range of advantages that can significantly improve the reliability and efficiency of the cooling system. On the other hand, for applications with lower heat loads and cost-sensitive budgets, non-split flow cold plates may still be a viable option. As the demand for more efficient thermal management solutions continues to increase.

For excample, For the regular PC water block, The low-cost budget of the non-divided microchannel water cooling plate has an absolute advantage in occupying the market of most ordinary users.

But for the high power AI server liquid cooling system,The application of high-power chips in the field of AI servers, the split-flow microchannel water cold plate will be an effective guarantee for the stable heat dissipation and long-term use of the server.

PREVIOUS:

Online Message

Any interest in Vansim.

We'll be appreciate and serve you wholeheartedly , Want to learn more about what we do, have questions or need a quote?