-

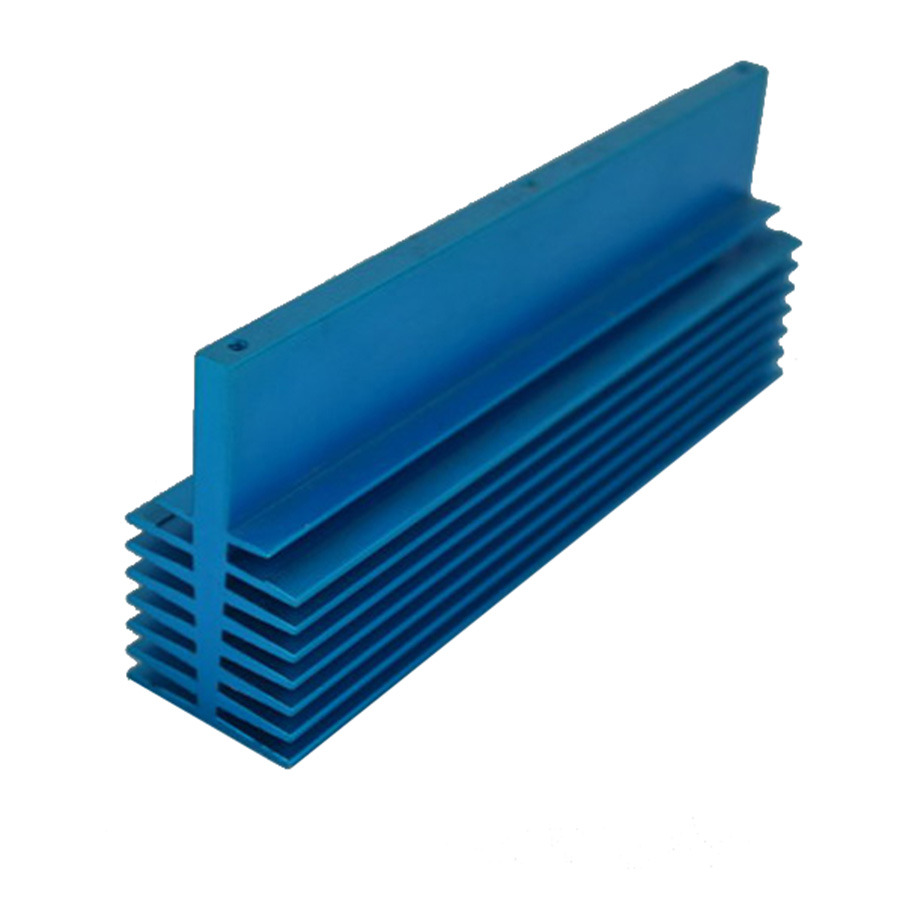

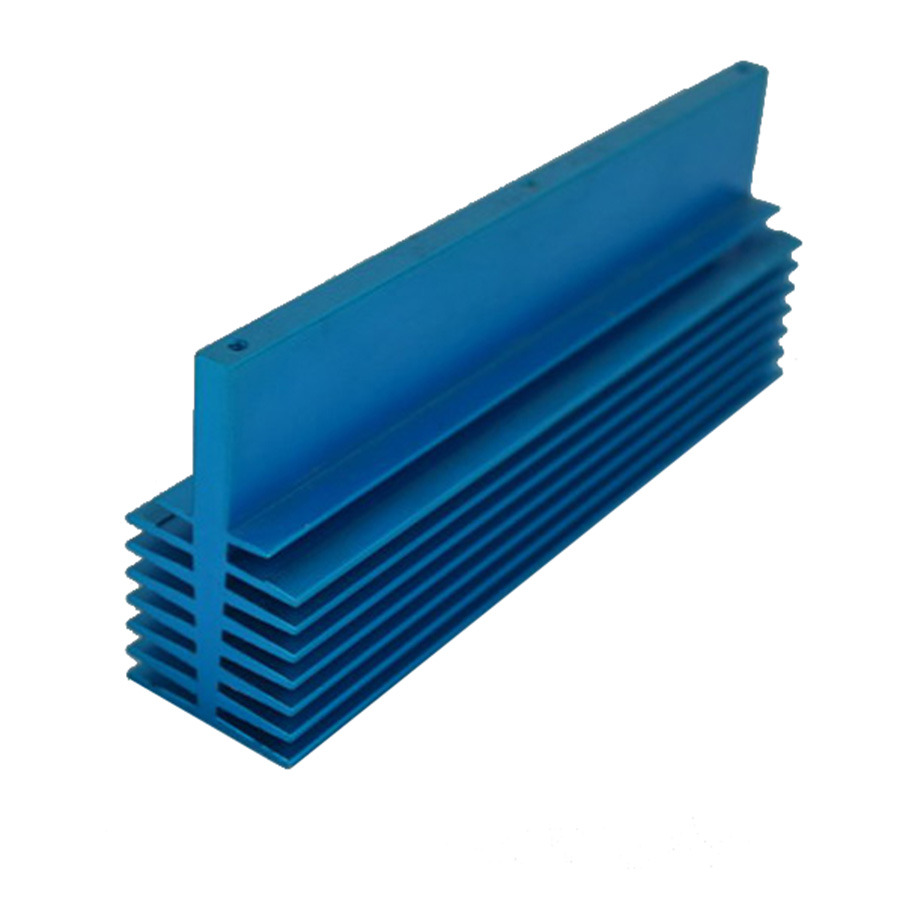

power amplifier Extrusion Heat Sink

Our products include cooler, liquid cold plate, heat pipe heat sink, skived heatsink, extruded heatsink, soldered heatsink, swaged heat sink, bonded heatsink ,auto parts, aluminum structural parts, CNC machined parts, Precision CNC machining parts .

Used on power supply, drivers, soft starter, energy storage, inverter ,IGBT modules, fiber laser, smart driving,semiconductor cooling2021-06-22 -

Extrusion Power inverter enclosure

Our products include cooler, liquid cold plate, heat pipe heat sink, skived heatsink, extruded heatsink, soldered heatsink, swaged heat sink, bonded heatsink ,auto parts, aluminum structural parts, CNC machined parts, Precision CNC machining parts .

Used on power supply, drivers, soft starter, energy storage, inverter ,IGBT modules, fiber laser, smart driving,semiconductor cooling2021-06-22 -

Aluminum extrusion heat sink

Our products include cooler, liquid cold plate, heat pipe heat sink, skived heatsink, extruded heatsink, soldered heatsink, swaged heat sink, bonded heatsink ,auto parts, aluminum structural parts, CNC machined parts, Precision CNC machining parts .

Used on power supply, drivers, soft starter, energy storage, inverter ,IGBT modules, fiber laser, smart driving,semiconductor cooling2021-11-25 -

wavy fin extrusion heat sink

2021-11-15 -

Aluminum extrusion heat sink shell

2021-11-15 -

Extrusion heat sink

2021-07-15

Aluminum EXTRUDED HEAT SINK

Extrusion radiators are generally high power radiating components and cooling systems, according to the existing mature aluminum extrusion profile radiator technology, we can provide reliable natural convection environment solutions.Aluminum extrusion molding is realized through the die, which can realize the complex structure of heat dissipation teeth.These complex heat dissipation teeth increase the heat dissipation surface area, while reducing the cost and time of aluminum block processing.

Why use extruded radiators?

(1) It is more efficient than the heat sink formed by stamping;

(2) more cost saving than mechanical processing;

(3) A variety of standard shapes and sizes are available;

(4) Easy customization is lighter than copper, with obvious advantages;

(5) The MAX CLIP coupler system does not need to install hardware and tools.

Design Parameters

The basic parameter of extrusion is as below:The basic parameter of extrusion is as below

- 机台吨位对角线尺寸倍数(齿高/齿间距)机台吨位对角线尺寸倍数(齿高/齿间距)

- 600T<120mm242750T<250mm21

- 880T<130mm243000T<320mm20

- 1000T<150mm223600T<350mm20

- 1500T<180mm224000T<400mm20

- 1800T<200mm216500T<540mm19

- 2500T<230mm218000T<700mm16

About Us

Product Service

Contact Us

Cell:+86 138 2691 1113 / +86 139 2943 3157

E-mail:bill@vansim.com alin@vansim.com

Address:No. 10, Minying West Road, Hengli Town, Dongguan City, China 523390