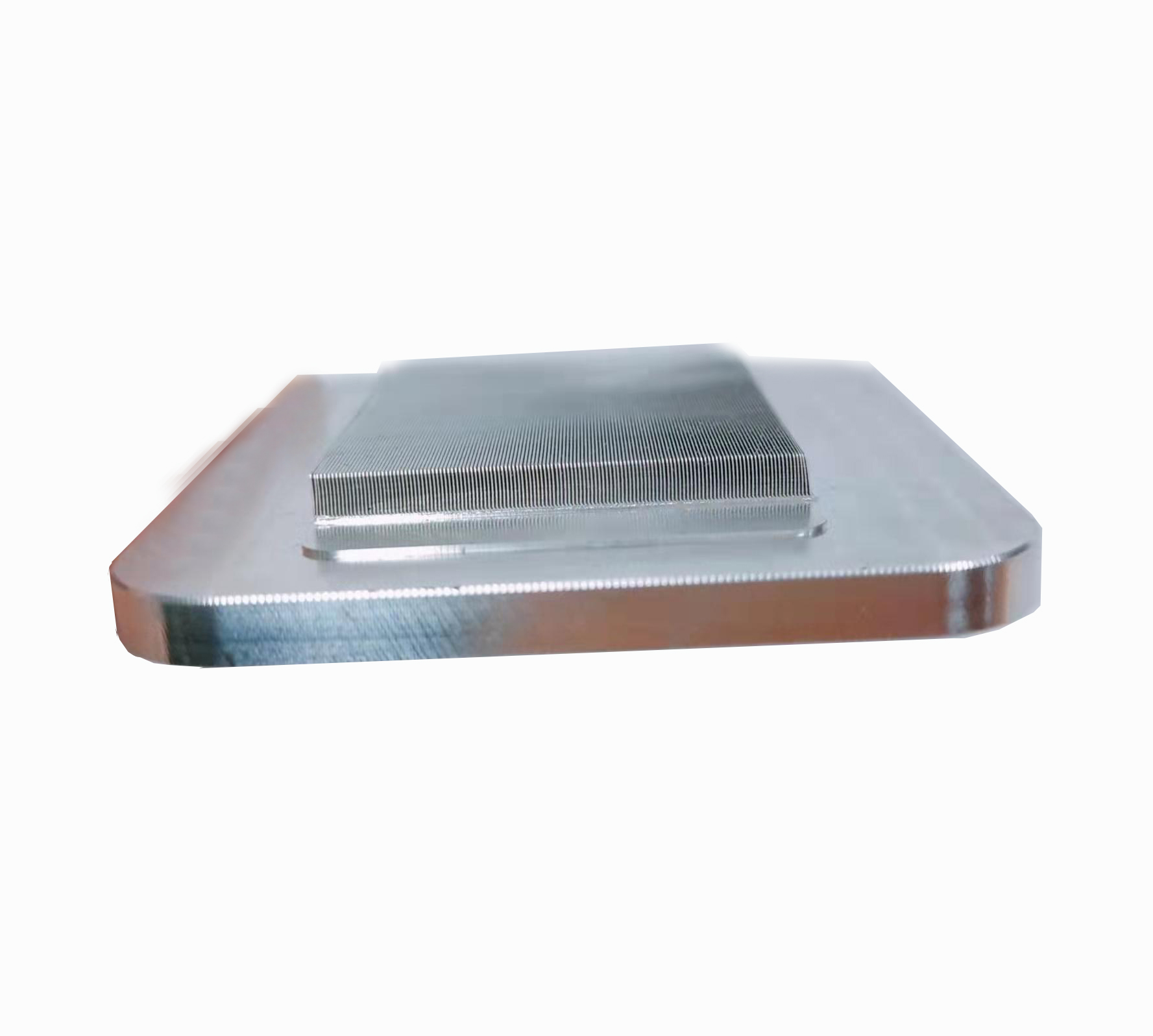

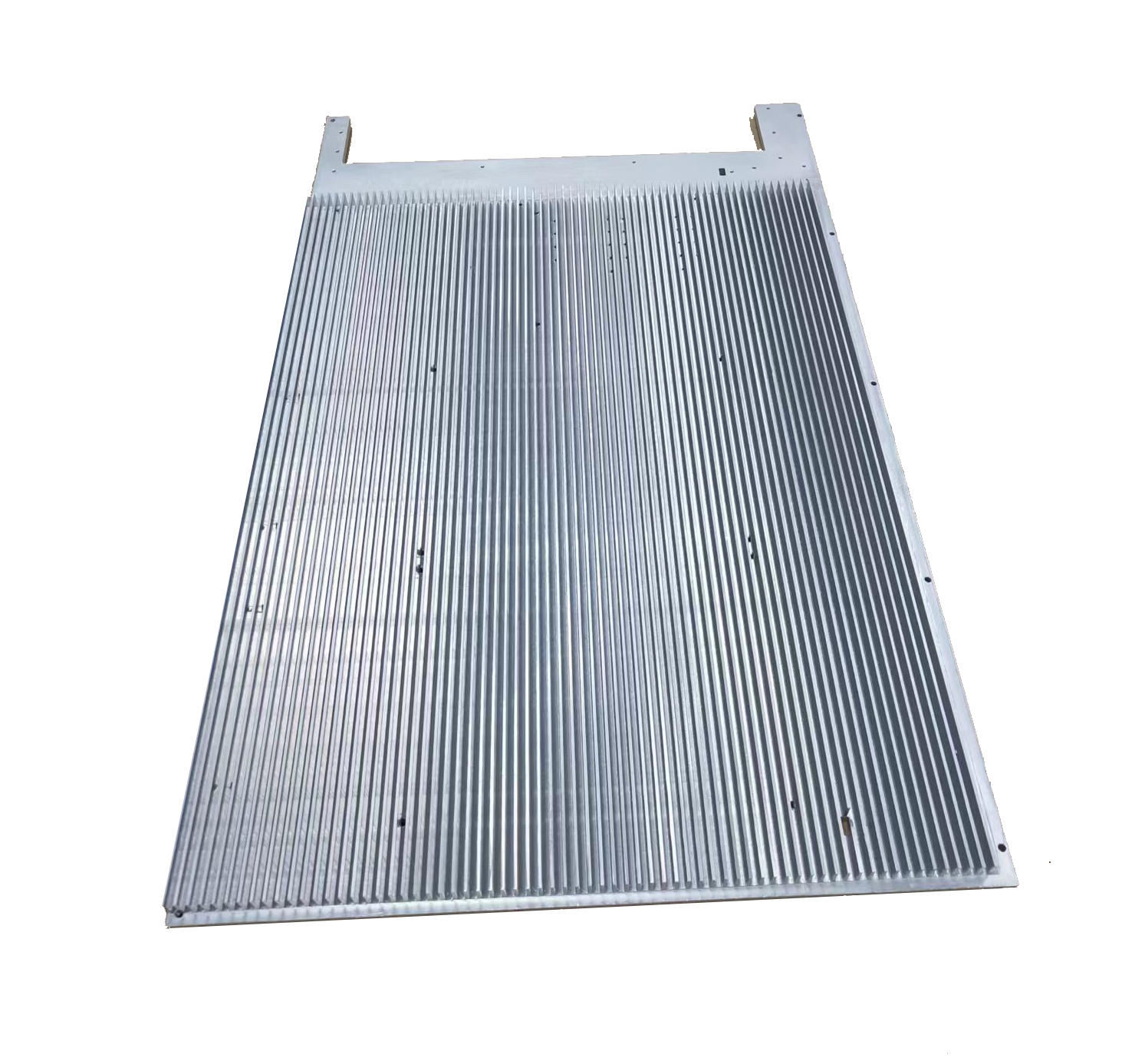

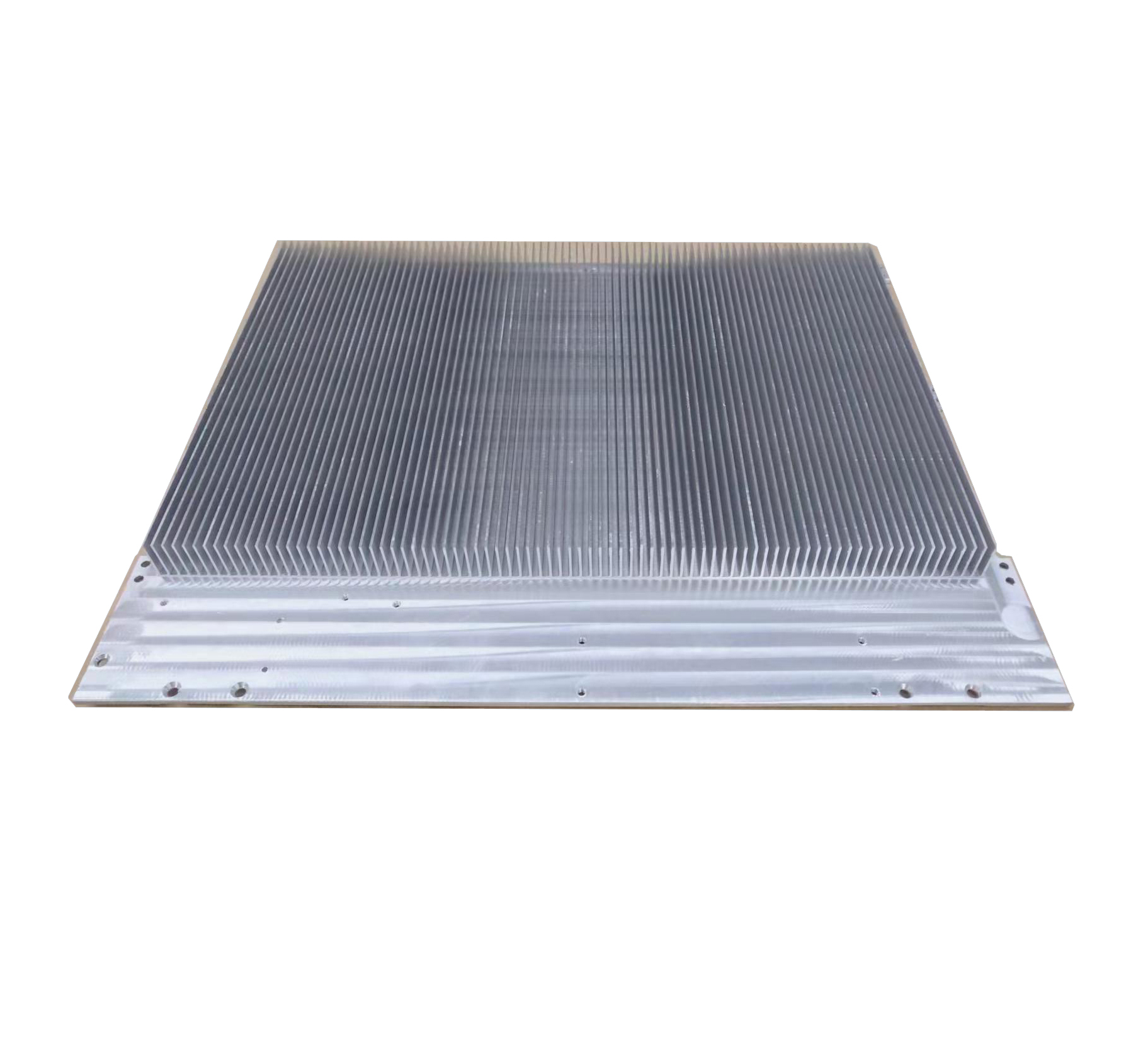

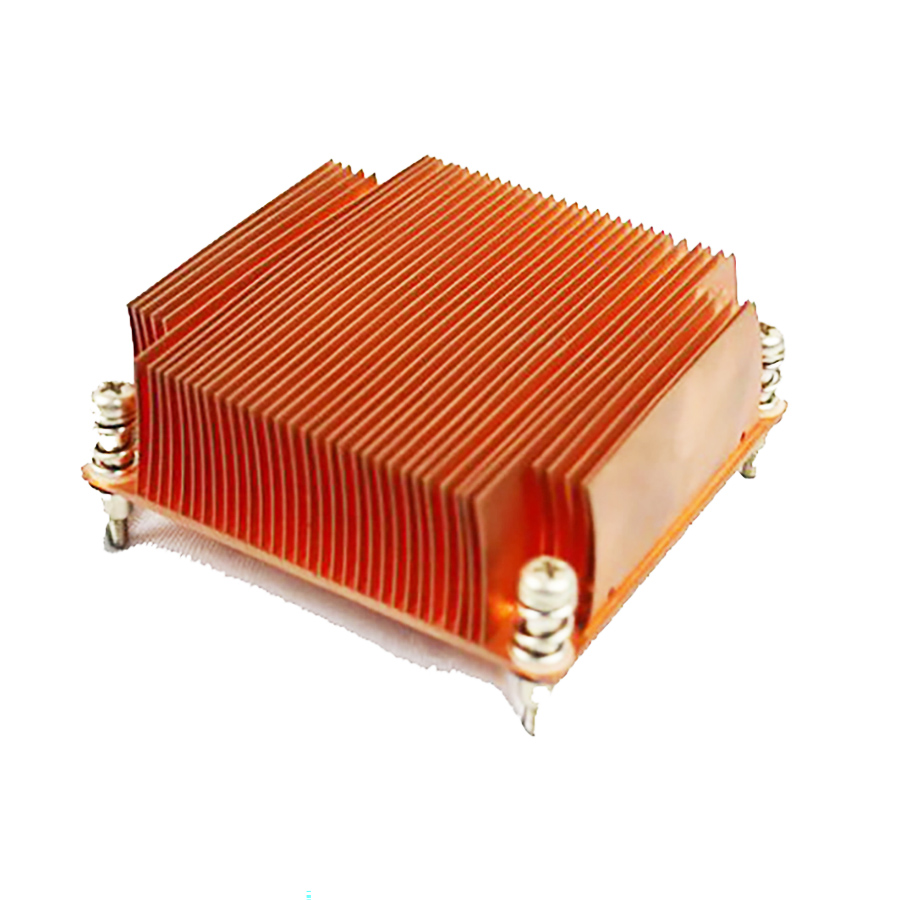

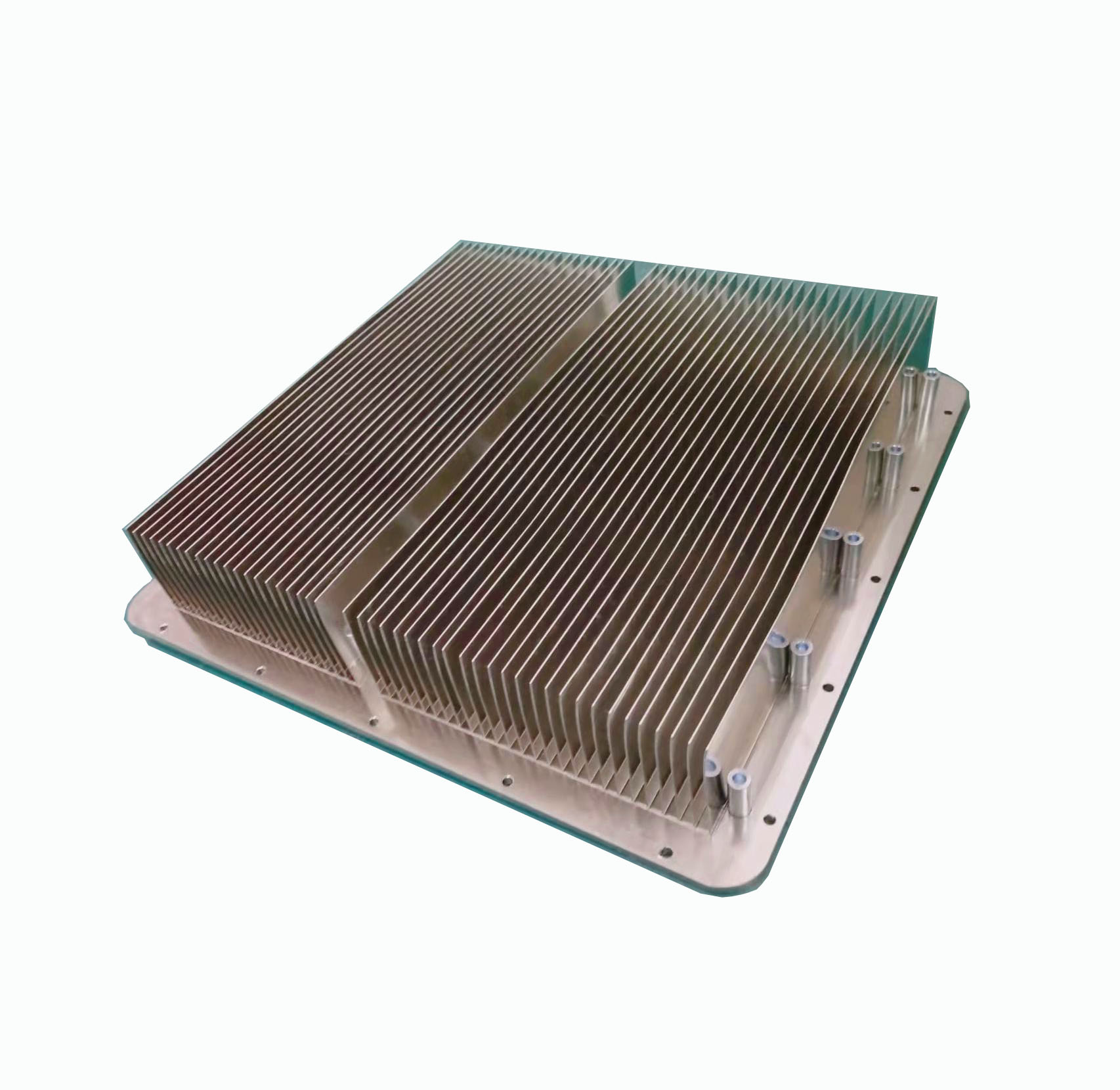

Skived fin heat sink

With the gradual enhancement of the degree of automation, we demonstrate the apparent advantage from the aspects of cost and reliability. Widely used the telecommunication, inverters, controllers, wind power converters.

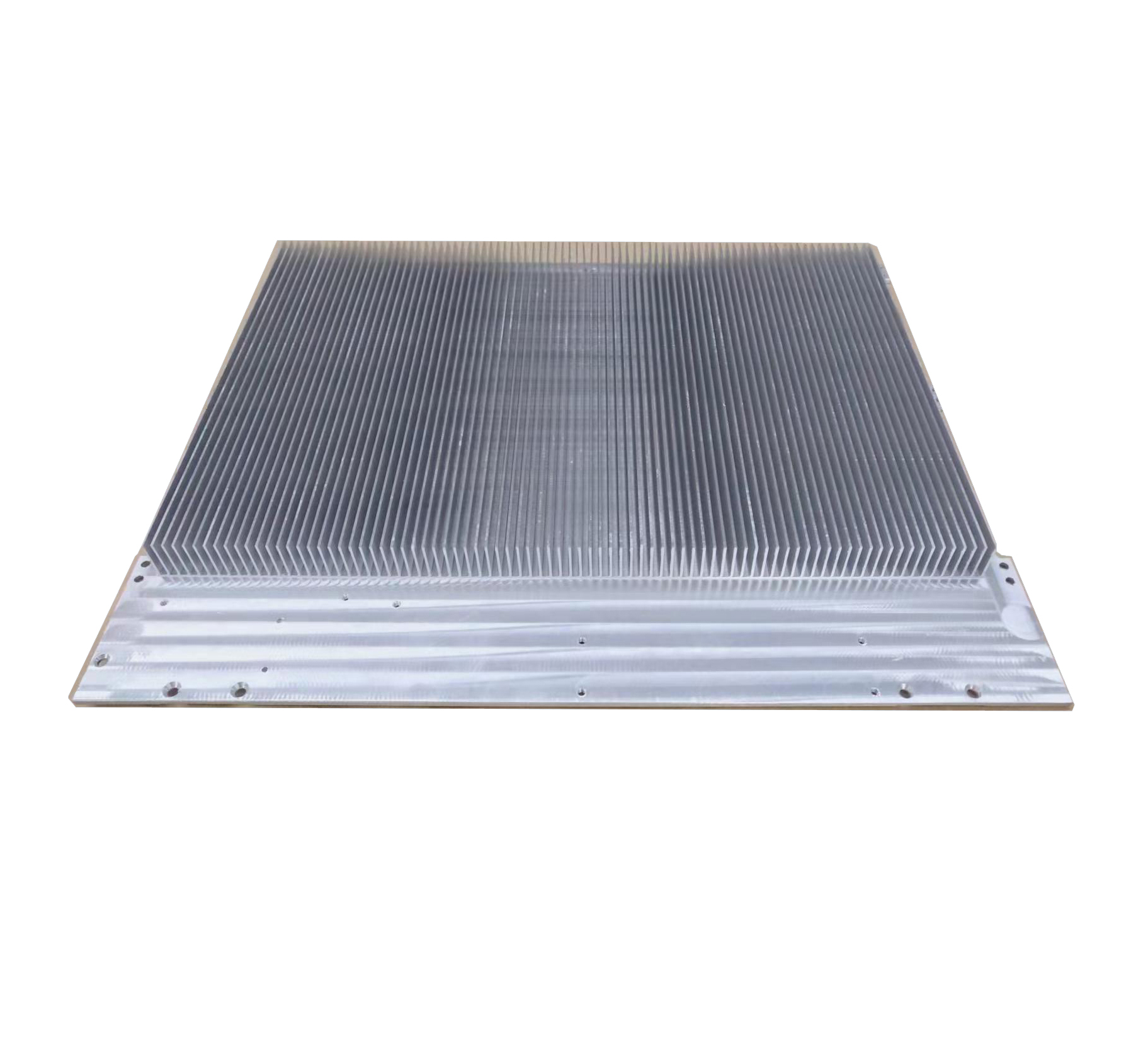

Skived fin heat sinks: When passing through the machine, slabs are skived in a specific angle so as to form and bend the fins. With the repetitive cutting, it forms consistent gaps and structures and can be used for cooling high-power devices under air-cooled conditions. This process can enhance 8~15% of the cooling capacity as compared to the stitched fin process.

视频播放失败,请联系站点管理员!

AL Process parameters:

|

Base thickness |

Fin length |

Fin height |

Fin thickness |

Fin gap |

Product length |

|

1~30mm |

﹤550mm |

﹤120mm |

0.1~2.0mm |

0.1~6.5mm |

1000mm |

|

Base thickness |

Fin length |

Fin height |

Fin thickness |

Fin gap |

Product length |

|

1~30mm |

﹤550mm |

﹤120mm |

0.1~2.0mm |

0.1~6.5mm |

1000mm |

-

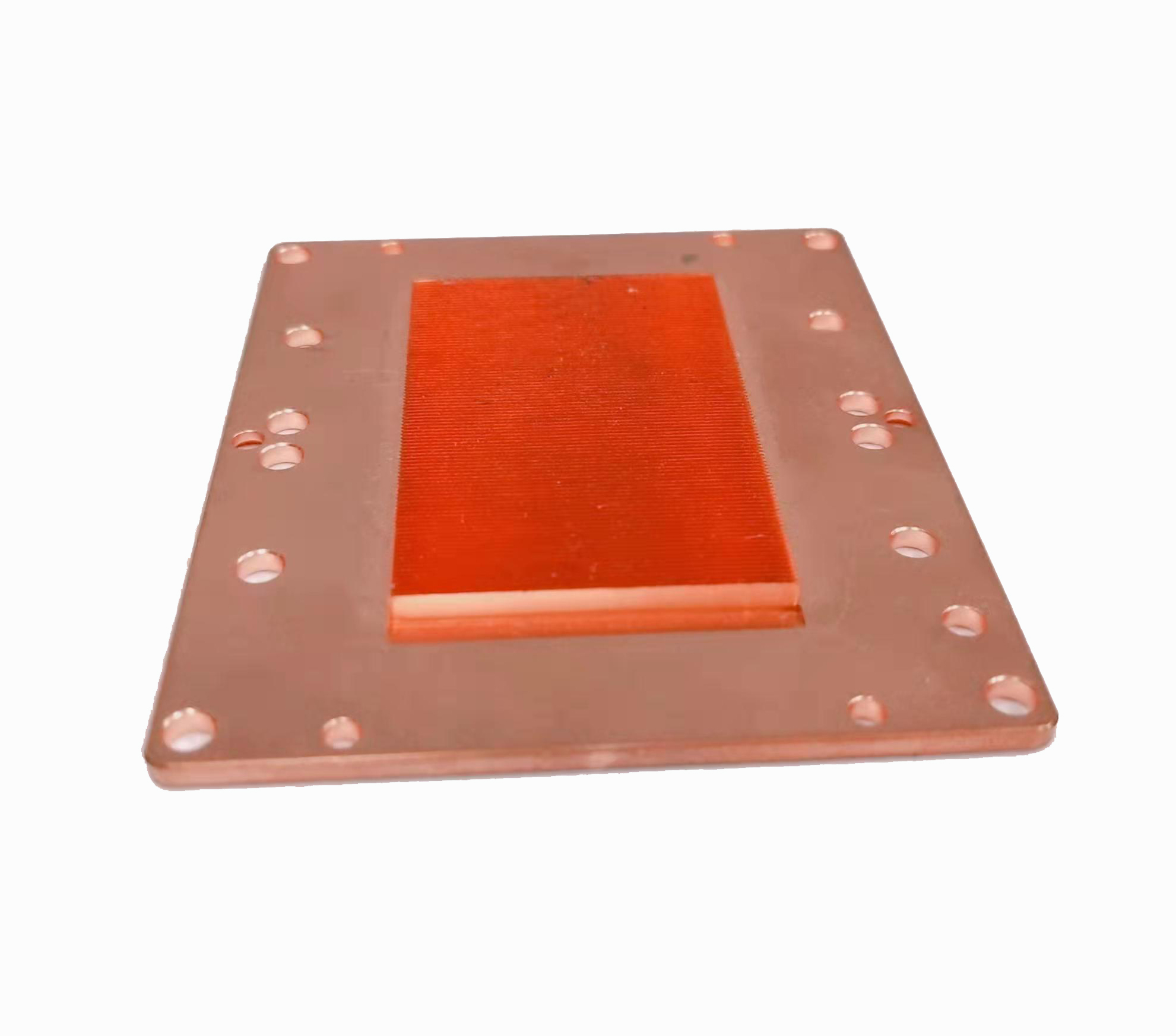

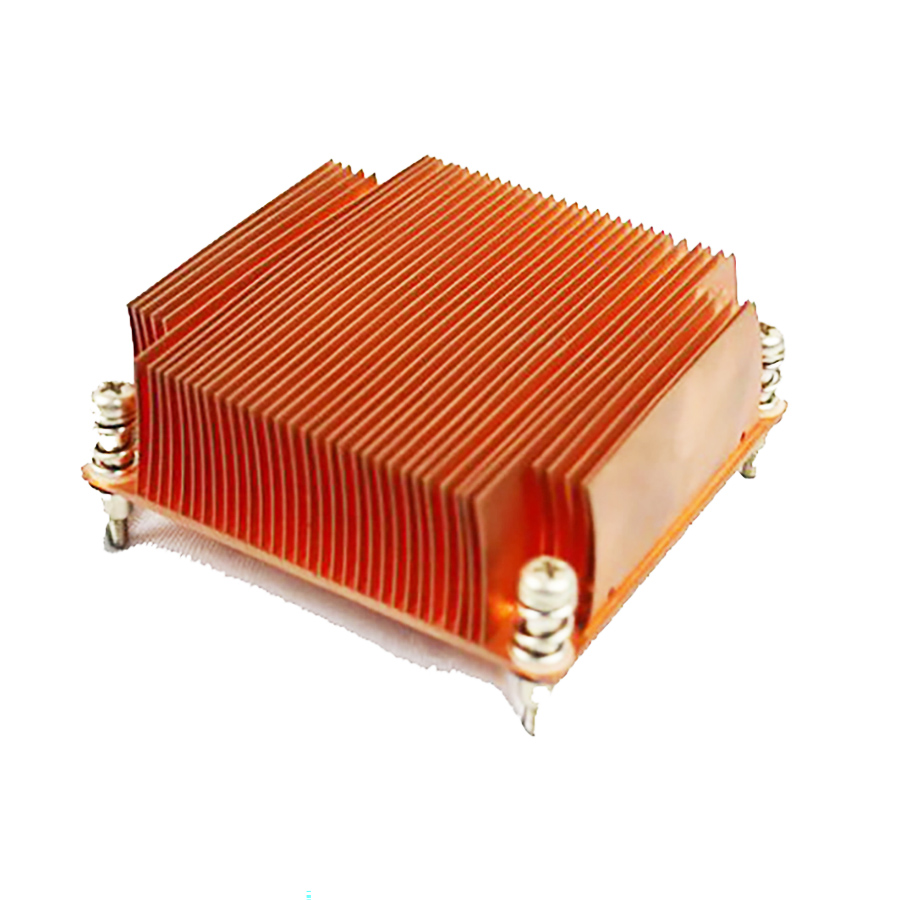

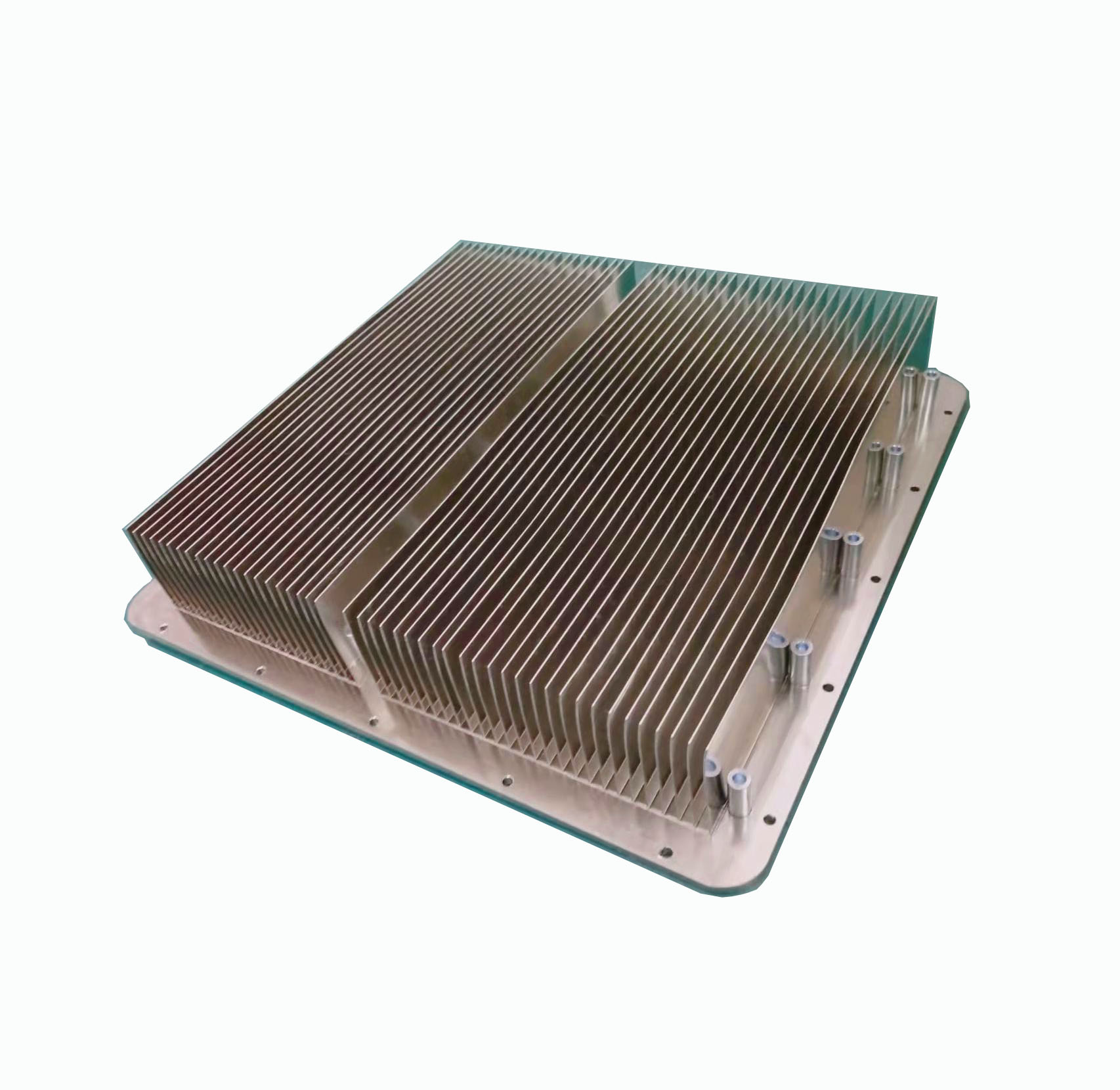

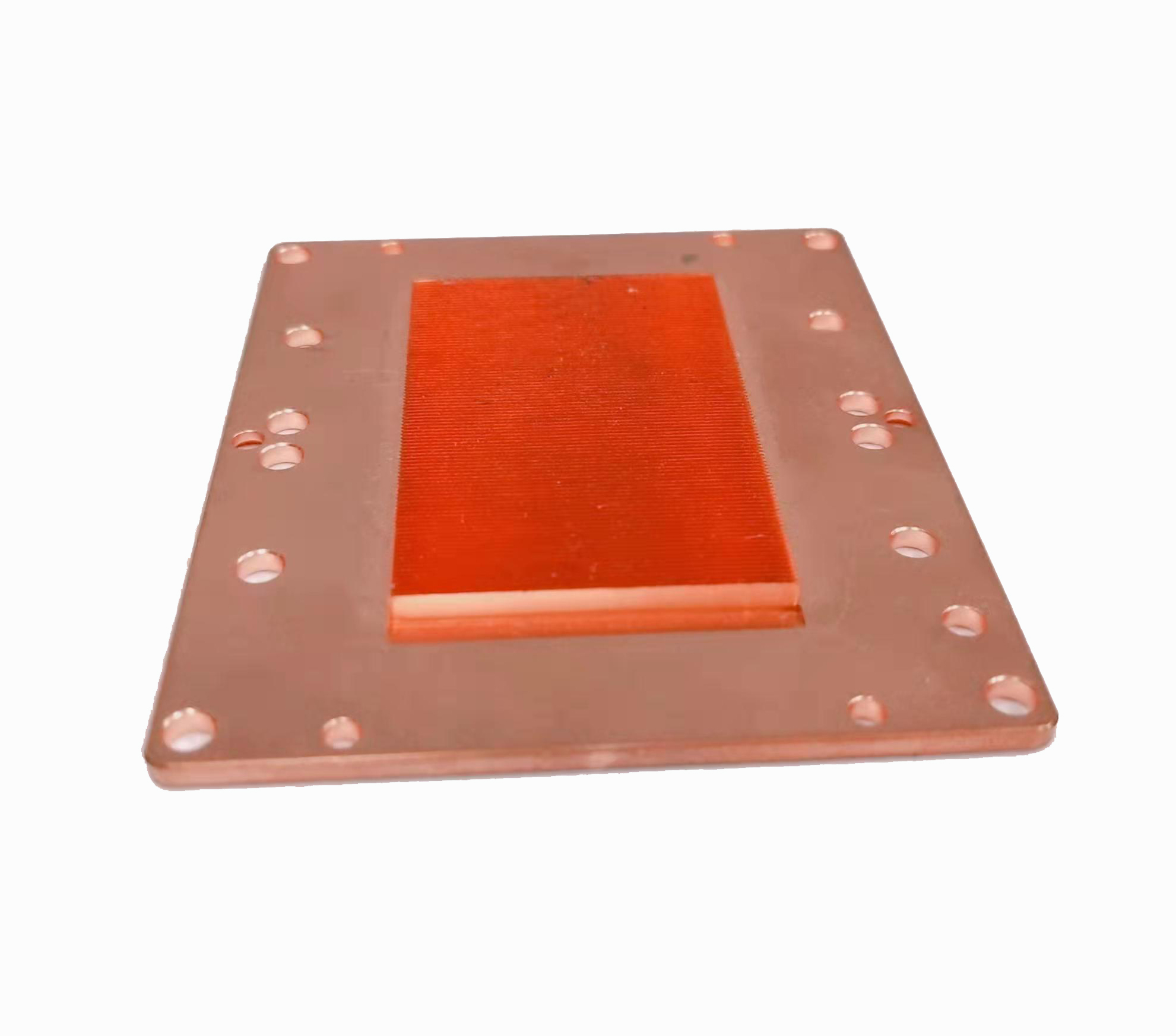

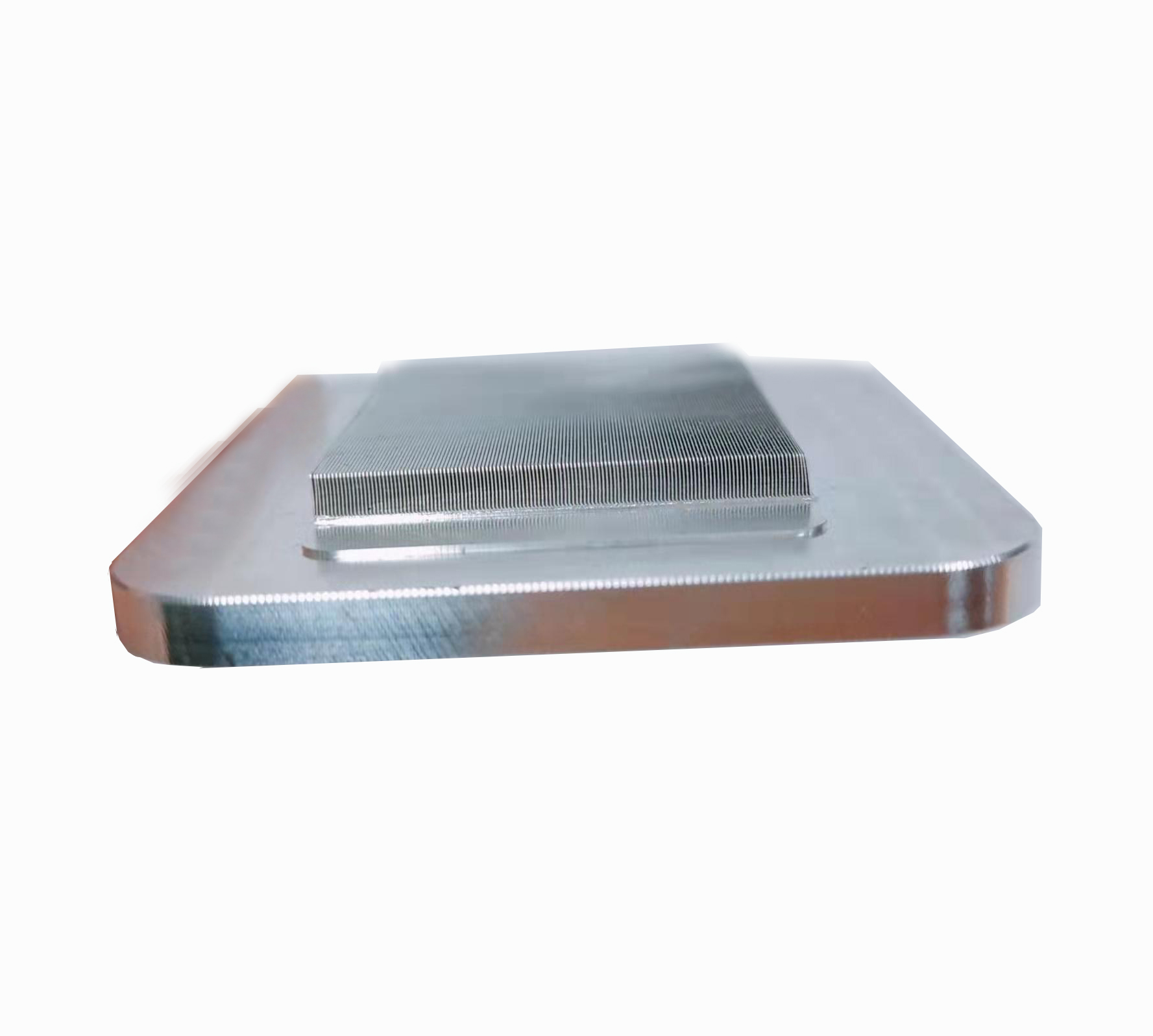

high density copper skived heat sink for micro-channel cold plate

2022-10-07 -

micro-channel liquid cold plate used high density copper skived heat sink

2022-10-07 -

High Density Copper skiving fin heat sink

2021-11-23 -

high density aluminum skived heat sink used for micro-channel liquid cold plate

2022-10-07

Skived Heat Sinks For Micro-channel liquid cold plate

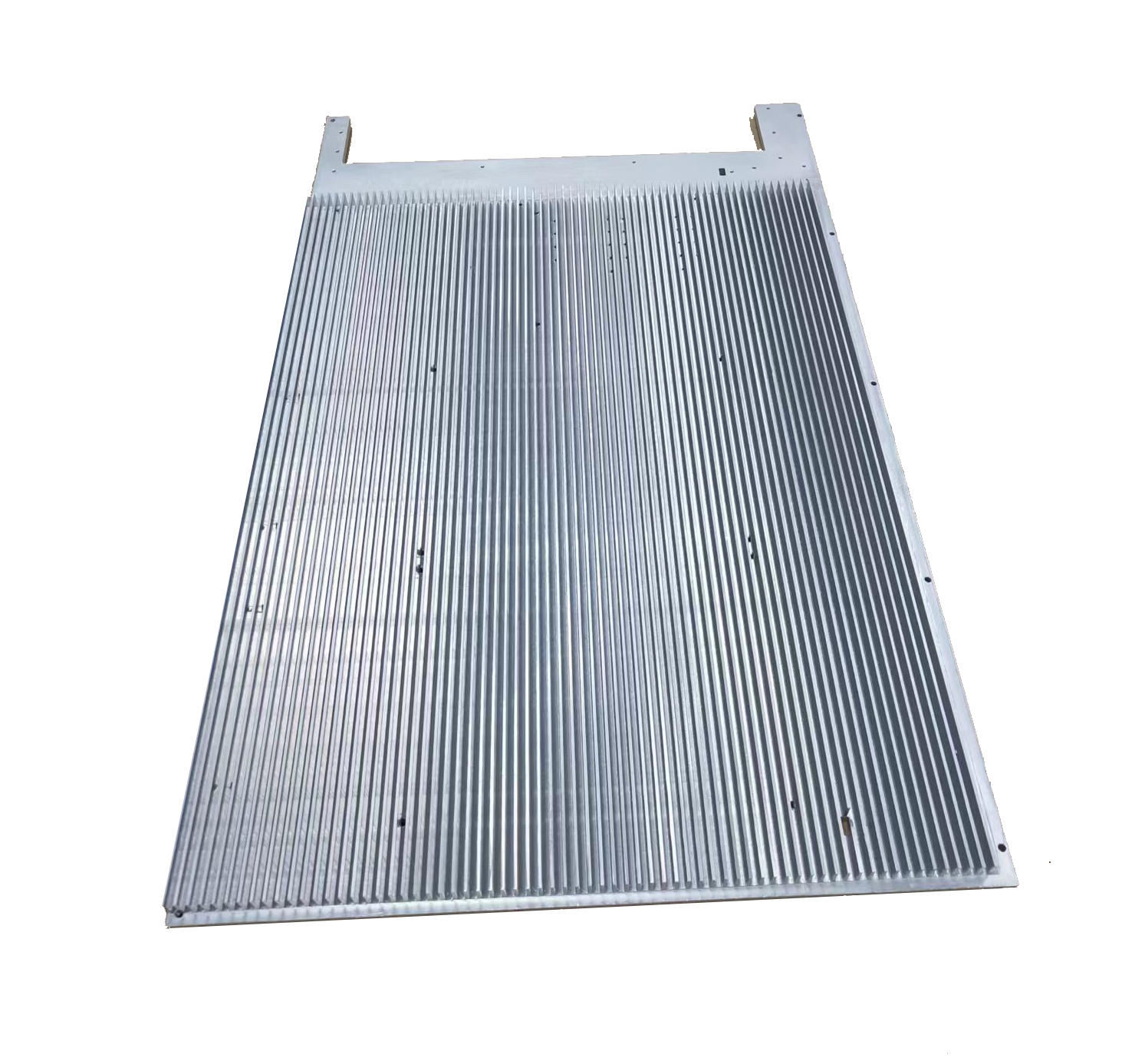

Skived Heat Sinks For Normal Cooling Products

-

laser heat dissipation aluminum skived heat sink

2022-10-07 -

copper skiving fin heat sink

2022-10-07 -

fibre laser heat dissipation aluminum skived heat sink

Our products include cooler, liquid cold plate, heat pipe heat sink, skived heatsink, extruded heatsink, soldered heatsink, swaged heat sink, bonded heatsink ,auto parts, aluminum structural parts, CNC machined parts, Precision CNC machining parts .

Used on power supply, drivers, soft starter, energy storage, inverter ,IGBT modules, fiber laser, smart driving,semiconductor cooling2022-10-07 -

optical fiber skiving fin heat sink combination

2021-12-11 -

copper skiving fin heat sink

2021-12-03 -

Aluminum skiving fin heat sink

2021-12-03 -

double-faced skiving fin heat sinks

2021-10-25 -

Bellows aluminum skiving fin heat sink

2021-10-25

About Us

Product Service

Contact Us

Cell:+86 138 2691 1113 / +86 139 2943 3157

E-mail:bill@vansim.com alin@vansim.com

Address:No. 10, Minying West Road, Hengli Town, Dongguan City, China 523390