What is Vansim's manufacturing process of embedded copper tube liquid cooling plate ?

How to design and selecte material for the copper tube cold plate ?

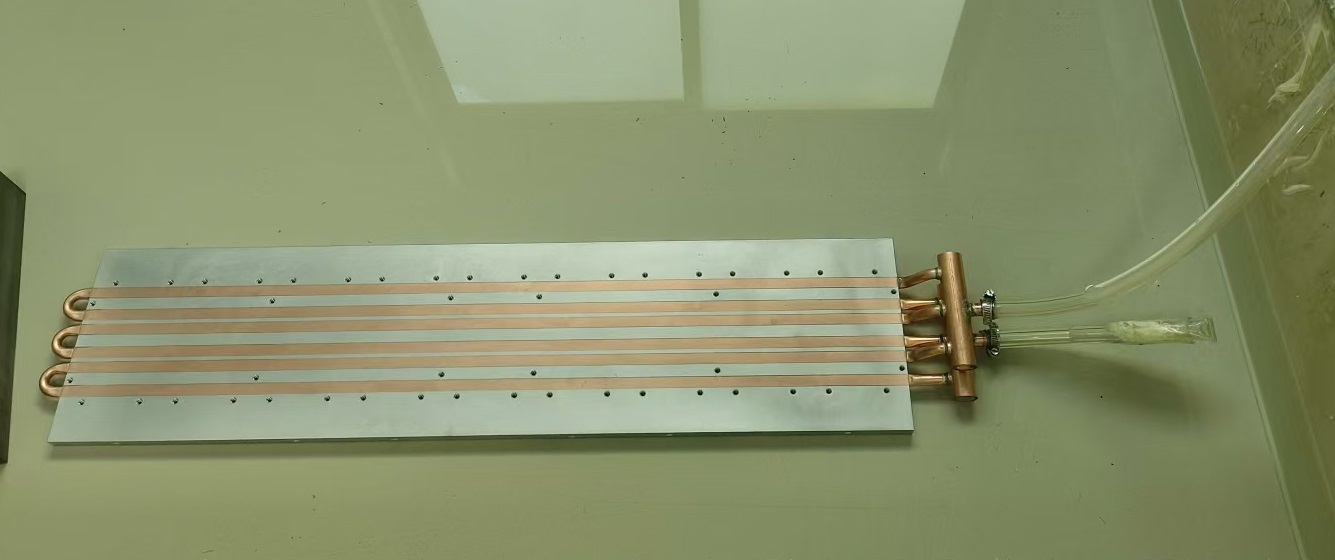

- Design: According to the use requirements, use professional software to design the structure of the water cooling plate, determine the size, shape, copper tube layout and other parameters.

- Material selection: Select suitable metal materials, such as aluminum alloy (if the cost is not considered, copper can also be selected as the substrate), because it has good thermal conductivity and corrosion resistance. At the same time, select copper tubes that meet the specifications to ensure its thermal conductivity and strength.

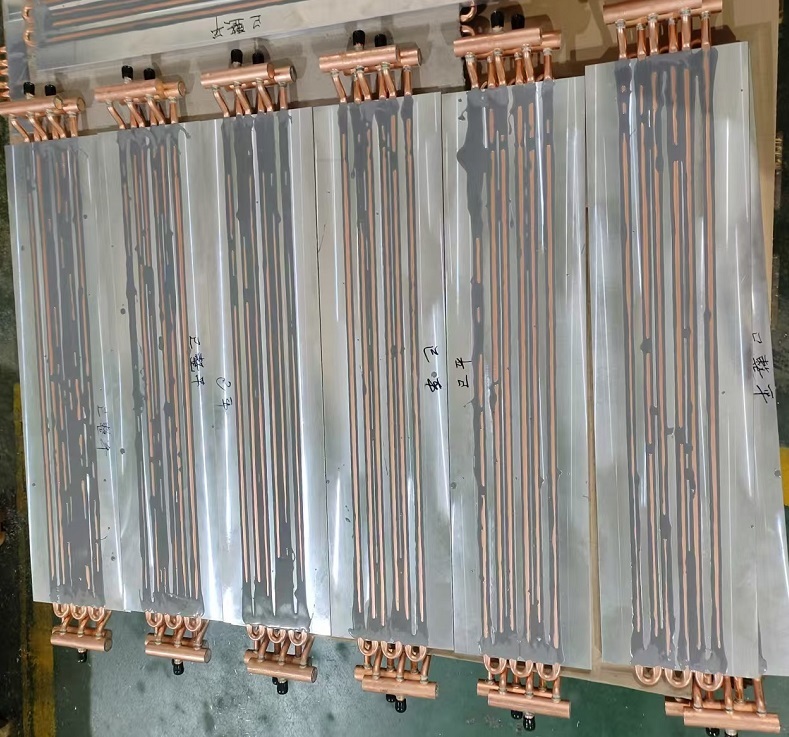

What's the processing to manufacturing the copper tube for cold plate?

- Cutting: According to the design size, use cutting equipment to cut the copper tube into the required length.

- Bending: The copper tube is bent into a predetermined shape by a tube bending machine to adapt to the internal structure of the water cooling plate and ensure a good fit with the components to be cooled.

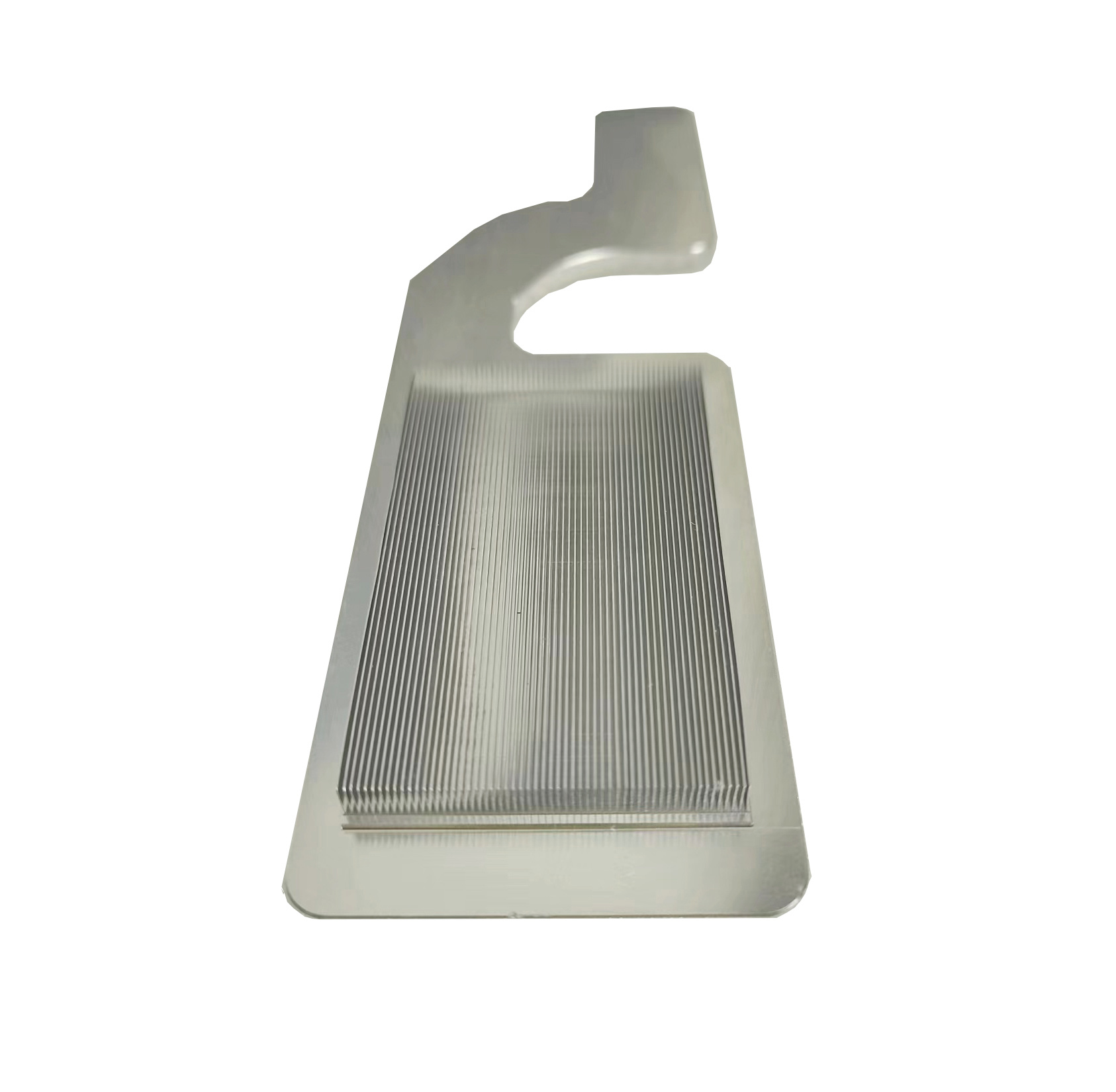

How to machining the substrate processing for the cold plate base?

- Slotting: According to the size and layout of the copper tube, the corresponding groove is processed on the substrate for placing the copper tube. Usually, a CNC machining center is used for precise slotting.

- Cleaning: Clean the aluminum alloy substrate to remove oil, impurities, etc. on the surface. Chemical cleaning agents or ultrasonic cleaning equipment can be used.

|  |

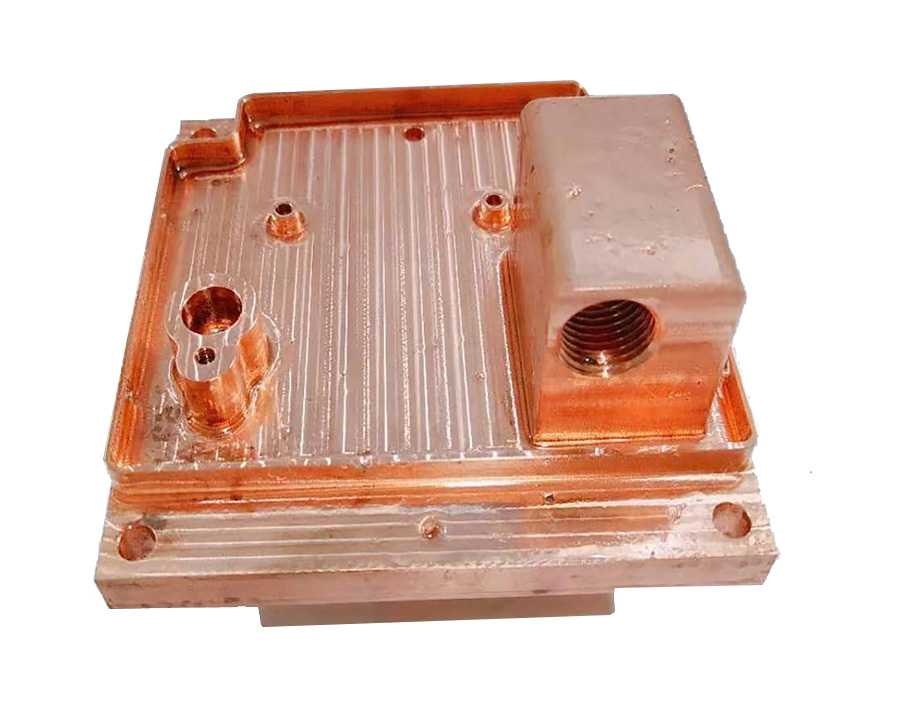

How to do the process of stamping the copper tubes into the base for the cold plate?

Buried pipe and epoxy filling

-Buried pipe: Put the processed copper tube into the groove of the substrate to ensure that the copper tube fits tightly with the groove wall.

- Glue filling: Use epoxy resin to fill the gap between the copper tube and the substrate. Special attention should be paid to fully stir the epoxy resin to avoid bubbles after drying.

What's the surface treatment is avaliable for the copper tube liquid cold plate?

- Passivation: Passivate the surface of the water-cooled plate to improve its corrosion resistance and wear resistance, and at the same time improve the appearance quality of the surface.

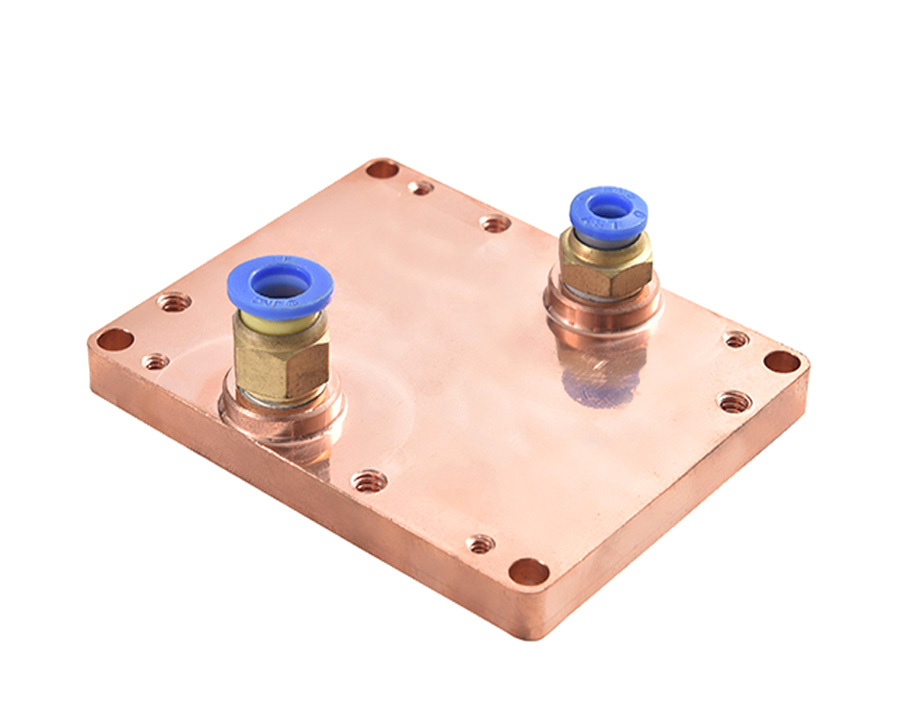

The greatest important process is the leackage test which is the quality guarantee for the liquid cold plate!

- Sealing test: Use water pressure or leakage testing

IGBT liquid cooling by copper tube cold plate

Contact Us

Classification