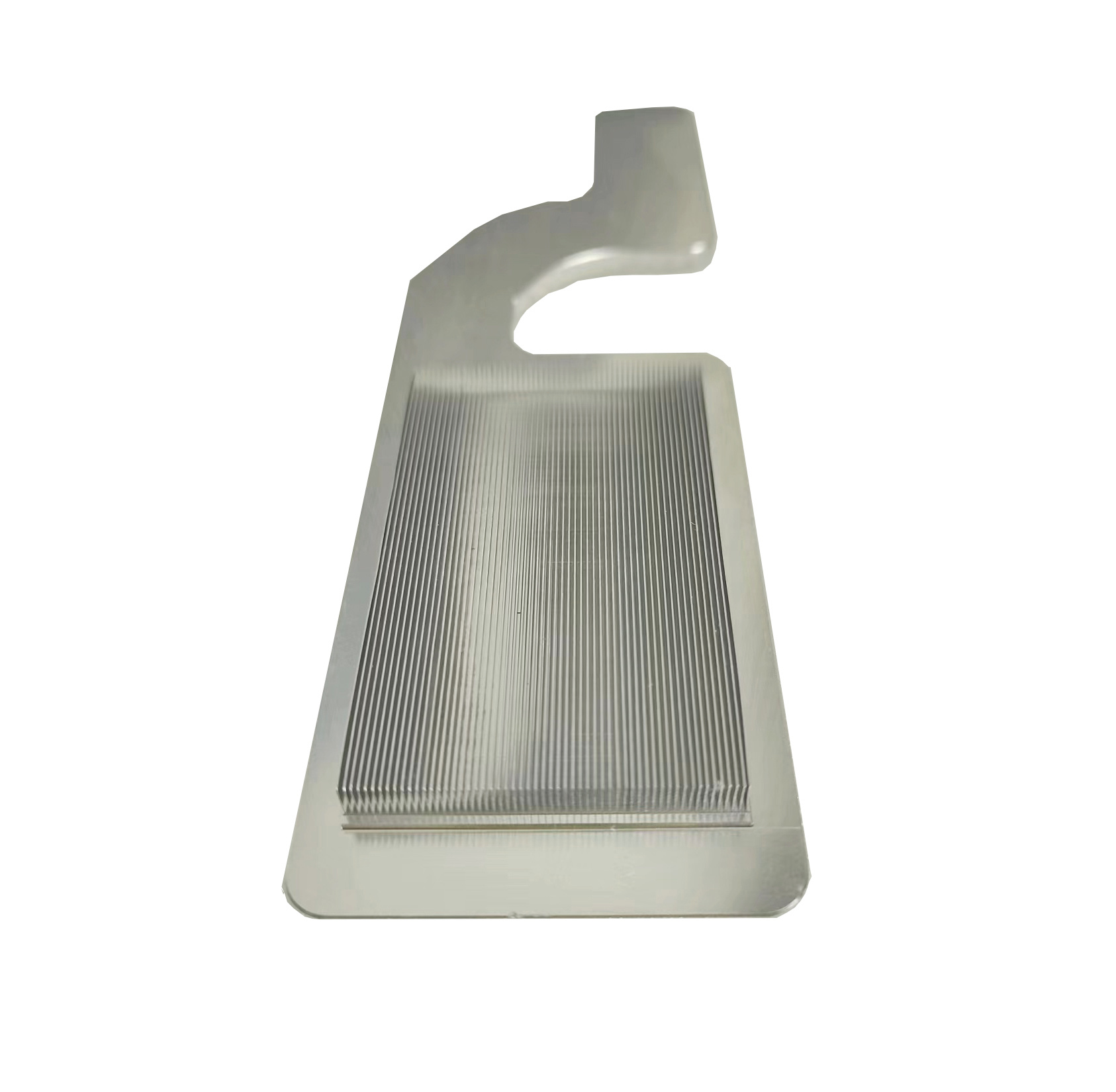

Aluminum Skived Heat Sink for Fiber Laser Air Cooling System with Optical Fiber Slots Machining

1. Product Overview

- High-efficiency heat dissipation via skived fin structure for laser components;

- Integrated optical fiber slots for precise fixing and routing of optical fibers, combining thermal and structural designs.

2. Key Technical Parameters

3. Machining Process Analysis

3.1 Skiving Machining

- Advantages:

- Enables thinner and denser fins (minimum thickness: 0.1 mm) compared to extrusion;

- One-piece fin-base structure eliminates welding thermal resistance for efficient heat transfer.

- Key Steps:

- Secure aluminum baseplate on CNC lathe or specialized skiving equipment;

- Use high-speed rotating tools to machine continuous fins transversely across the baseplate;

- Achieve precision via CNC programming (fin height/pitch tolerance: ±0.05 mm, surface roughness: Ra ≤3.2 μm).

3.2 Optical Fiber Slots Machining

- Process Options:

- Milling: Micro-milling cutters for rectangular/V-shaped slots (positioning accuracy: ±0.02 mm);

- Laser Machining (optional): Femtosecond laser for micron-scale slots with ultra-smooth walls.

- Design Considerations:

- Slot alignment must match fiber routing to avoid excessive bending (minimum curvature radius: ≥20 mm to prevent optical loss);

- Thermal contact gaps at slot bottoms ensure tight fiber-heatsink coupling.

4. Advantages in Fiber Laser Air Cooling Systems

- Enhanced Heat Dissipation:

- Dense fins increase surface area by 30–50% compared to traditional extruded heatsinks;

- Air-cooled design (with axial fans) maintains laser module junction temperature ≤60°C.

- Integrated Structure:

- Slots eliminate separate fiber-clamping components, reducing assembly steps;

- Mechanical protection against fiber abrasion during operation.

- Reliability:

- Lightweight aluminum (density: 2.7 g/cm³) suits airborne or mobile laser systems;

- Anodized surface offers electrical insulation (breakdown voltage ≥500 V) for safety.

5. Typical Applications

- Industrial Laser Machining: Pump modules and gain modules in fiber lasers (20 W–1500 W);

- Scientific & Medical Devices: Compact cooling for lidar systems or laser scalpels;

- Aerospace: High-performance, lightweight cooling for airborne laser systems.

optical fiber cooling skived heat sink

Contact Us

Classification