Manufacturing Process of Buried Heat Pipe Heat Sinks for Fiber Laser Air Cooling Systems

Overview of Buried Heat Pipe Heat Sinks

Customization Considerations

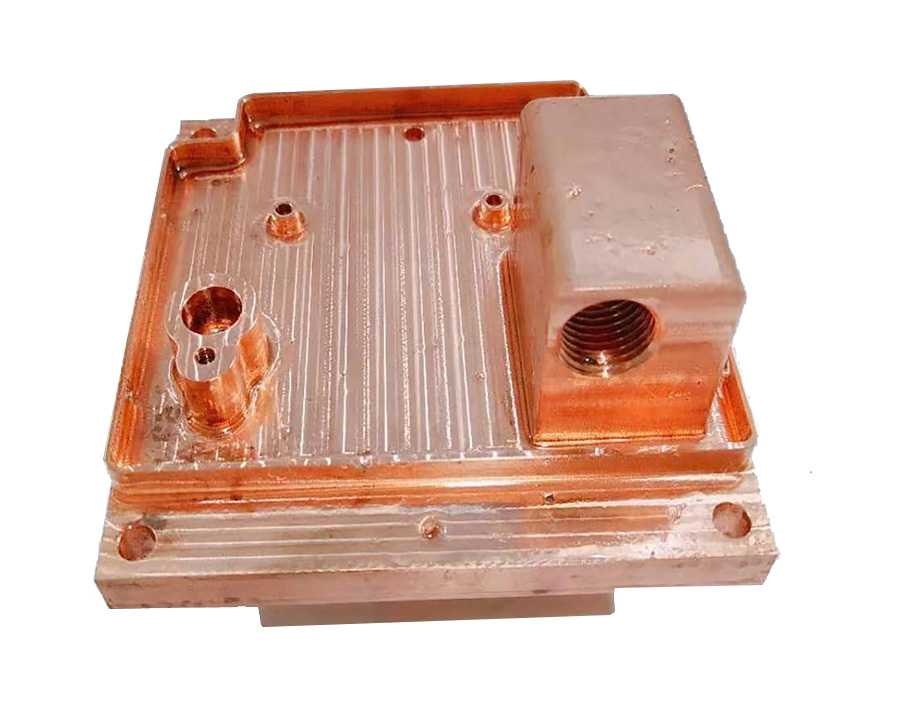

- Heat Pipe Layout:

- Serpentine or radial configurations for multi-heat-source systems (e.g., arrays of laser diodes).

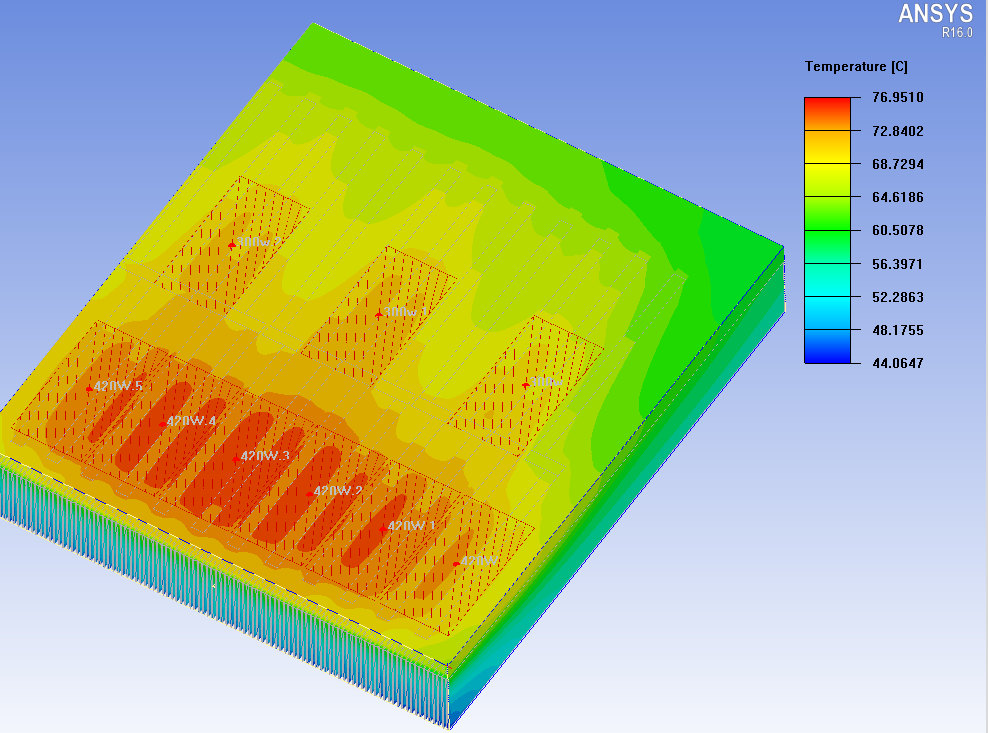

- Fin Optimization:

- Use computational fluid dynamics (CFD) to optimize fin pitch and height for target airflow rates (e.g., 2–5 m/s air velocity).

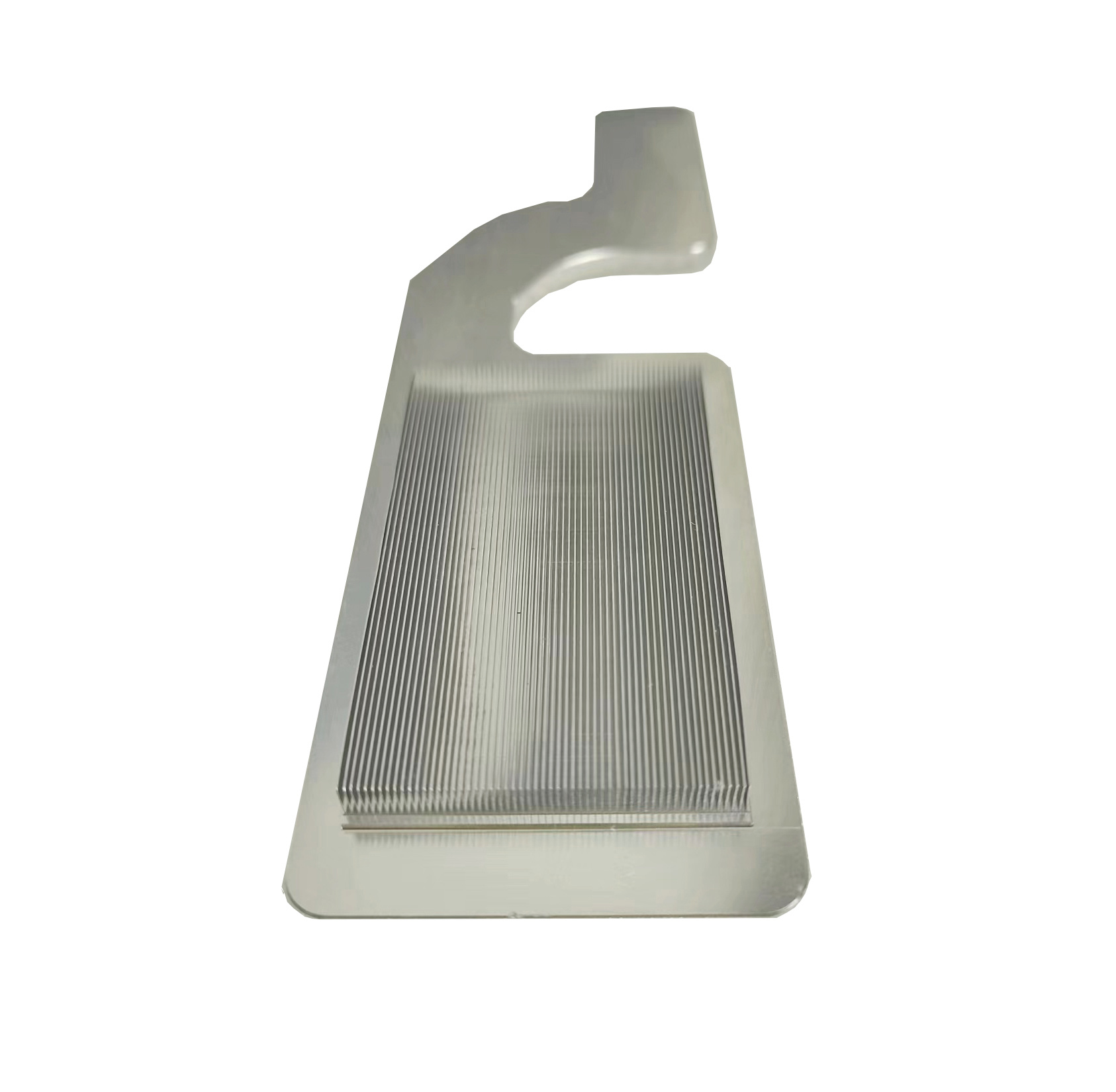

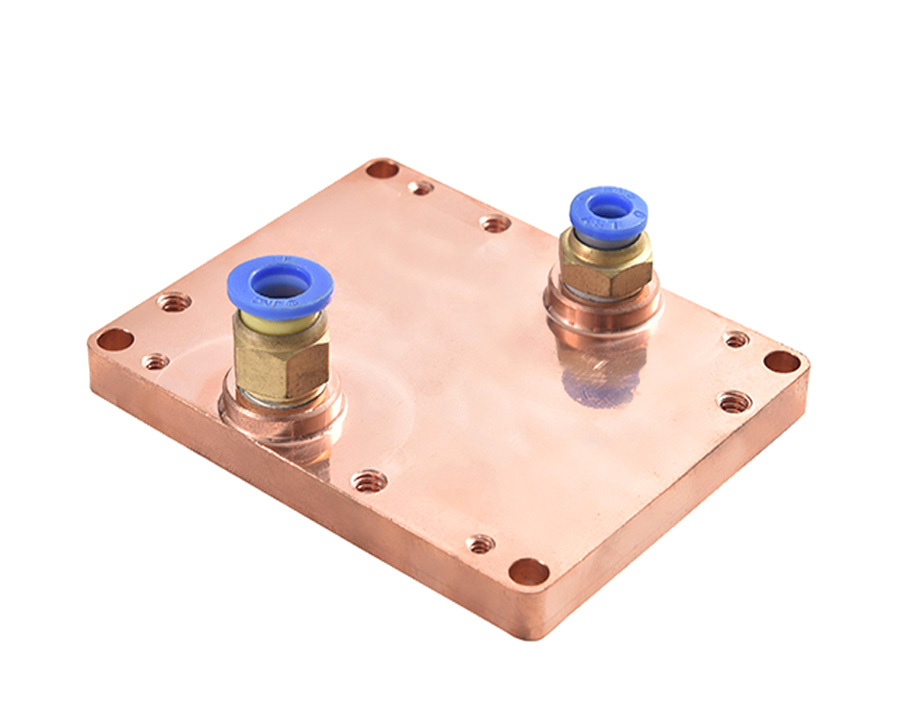

RF cooling heat pipe heat sink

Contact Us

Classification