What's the diffcults when do the process the skiving fin for the double-faced skiving fin heat sinks?

Challenges in Processing Double-FacedSkiving Fin Heat Sinks

|  |

|---|

Overcoming Challenges: Key Strategies

| Challenge | Root Cause | Impact on Process |

|---|---|---|

| Tool wear | Hard materials + high cutting forces | Inaccurate fins, increased downtime |

| Structural instability | High aspect ratio of thin fins | Deformed fins, reduced heat dissipation |

| Thermal distortion | Frictional heating during machining | Misalignment, warped base |

| Dual-sided precision | Need for symmetrical fin patterns | Complex fixturing, higher equipment costs |

| Chip evacuation | Trapped debris in confined fin spaces | Fin damage, tool clogging |

| Material constraints | Limited machinability of high-performance materials | Reduced design flexibility |

| High production costs | Subtractive, single-piece machining | Unsuitable for mass production |

|  |

- Advanced Tooling: Use diamond-coated tools or cryogenic cooling to extend tool life.

- Fin Support Structures: Incorporate temporary ribs or sacrificial material during machining to stabilize tall fins.

- Multi-Axis Machining: Leverage 5-axis CNC machines for precise dual-sided alignment.

- Material Optimization: Select alloys (e.g., 6063 aluminum) that balance thermal performance and machinability.What's the diffcults when do the process the skiving fin

- Automated Deburring and Cleaning: Integrate robotic systems to remove chips and burrs efficiently.

By addressing these challenges, double-faced skiving fin heat sinks can achieve optimal thermal performance in demanding applications, though they remain best suited for low-to-medium volume, high-precision scenarios.

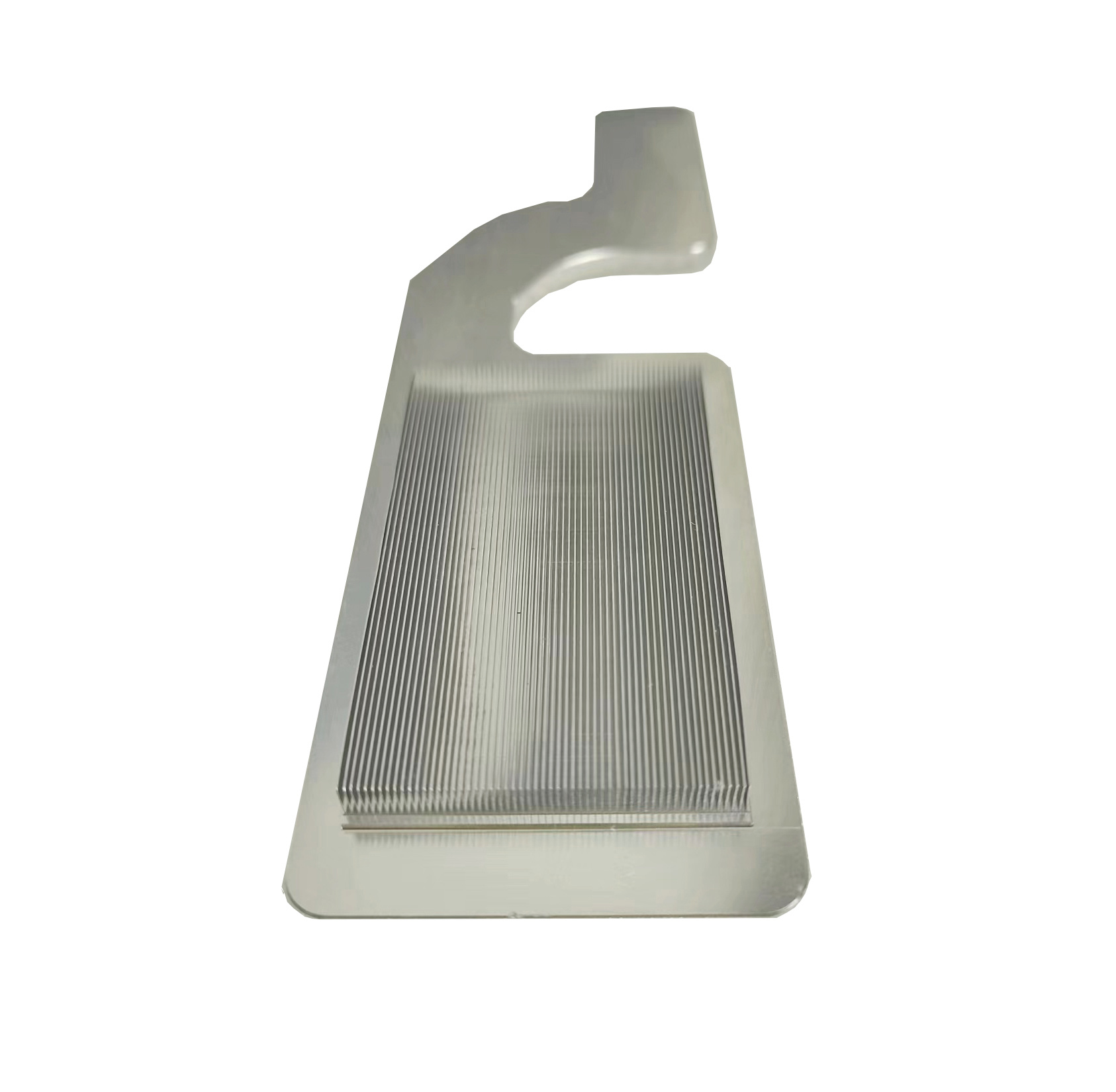

double-faced skiving fin heat sinks

The skiving process for double-faced fin heat sinks involves unique technical difficulties due to the need for high precision, material constraints, and structural complexity

Contact Us

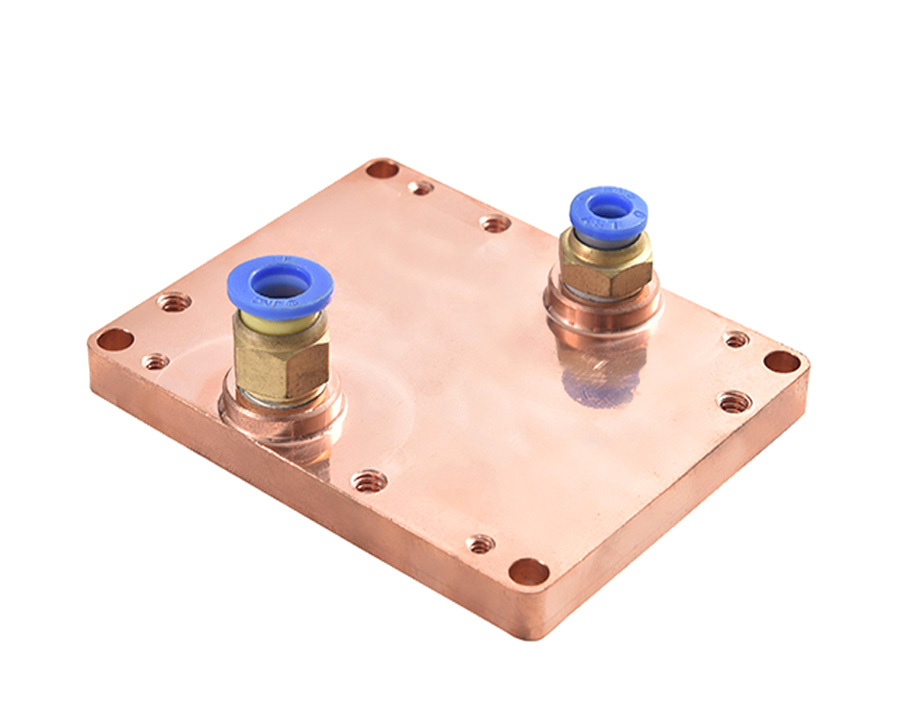

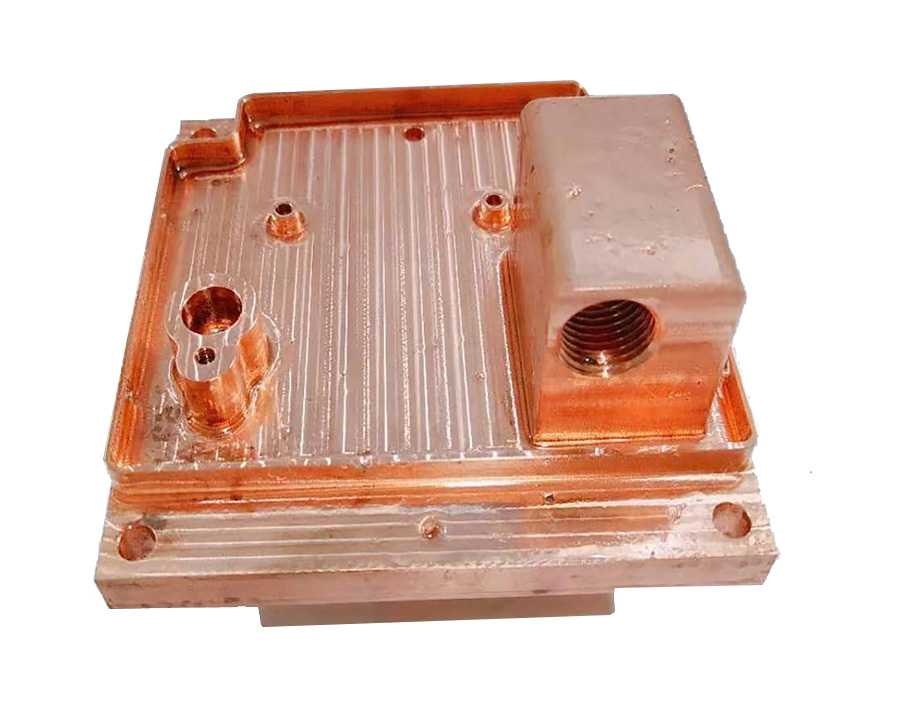

Related Products