For embedded copper tube liquid cooling plates, How about the material of the base compared with aluminum and copper?

When comparing the base materials (aluminum vs. copper) for embedded copper tube liquid cooling plates, the choice depends on thermal performance, mechanical properties, cost, and application requirements. Below is a detailed analysis of their characteristics and suitability:

Compared with aluminum and copper base for the copper tube cold plate's application scenarios:

| Scenario | Copper Base Suitable? | Aluminum Base Suitable? |

|---|---|---|

| High-power electronics (e.g., data center servers) | ✅ Ideal for extreme heat | ❌ Limited by thermal conductivity |

| Portable devices (e.g., laptops, gaming consoles) | ❌ Heavyweight | ✅ Lightweight and cost-effective |

| Automotive (e.g., EV battery cooling) | ✅ High reliability needed | ✅ Weight and cost priority |

| Industrial equipment (e.g., CNC machines) | ✅ Durable and high-performance | ❌ Unless heat load is moderate |

Summarize the key takeaways for take into consideration to choose the material for your copper tube cold plate design.

- Choose Copper for applications requiring maximal thermal performance and durability, even at higher cost and weight (e.g., server racks, aerospace).

- Choose Aluminum for cost-sensitive, lightweight scenarios with moderate heat loads (e.g., consumer electronics, automotive).

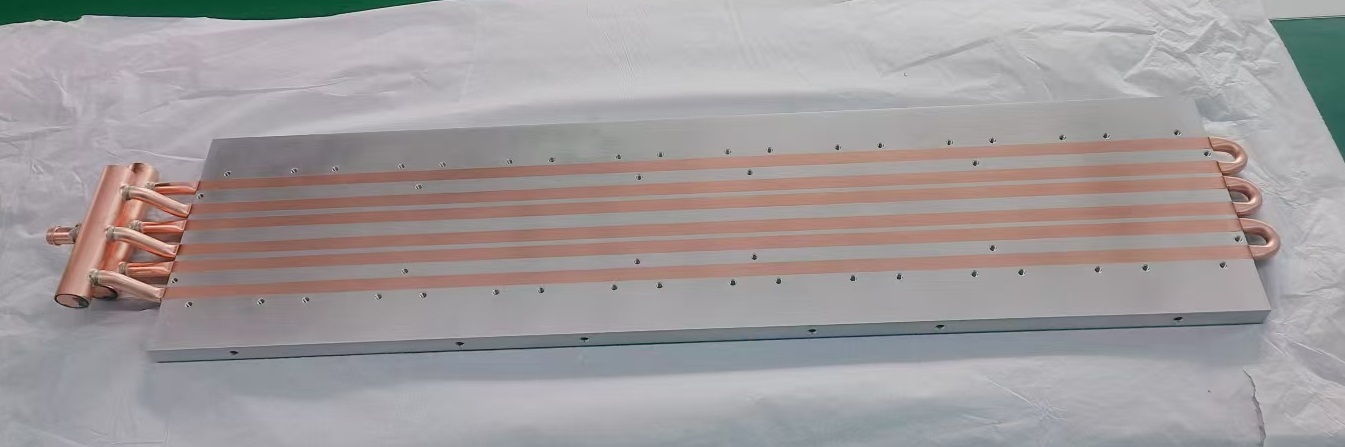

- Hybrid designs can optimize performance for specific use cases, but they add complexity to manufacturing and bonding processes.

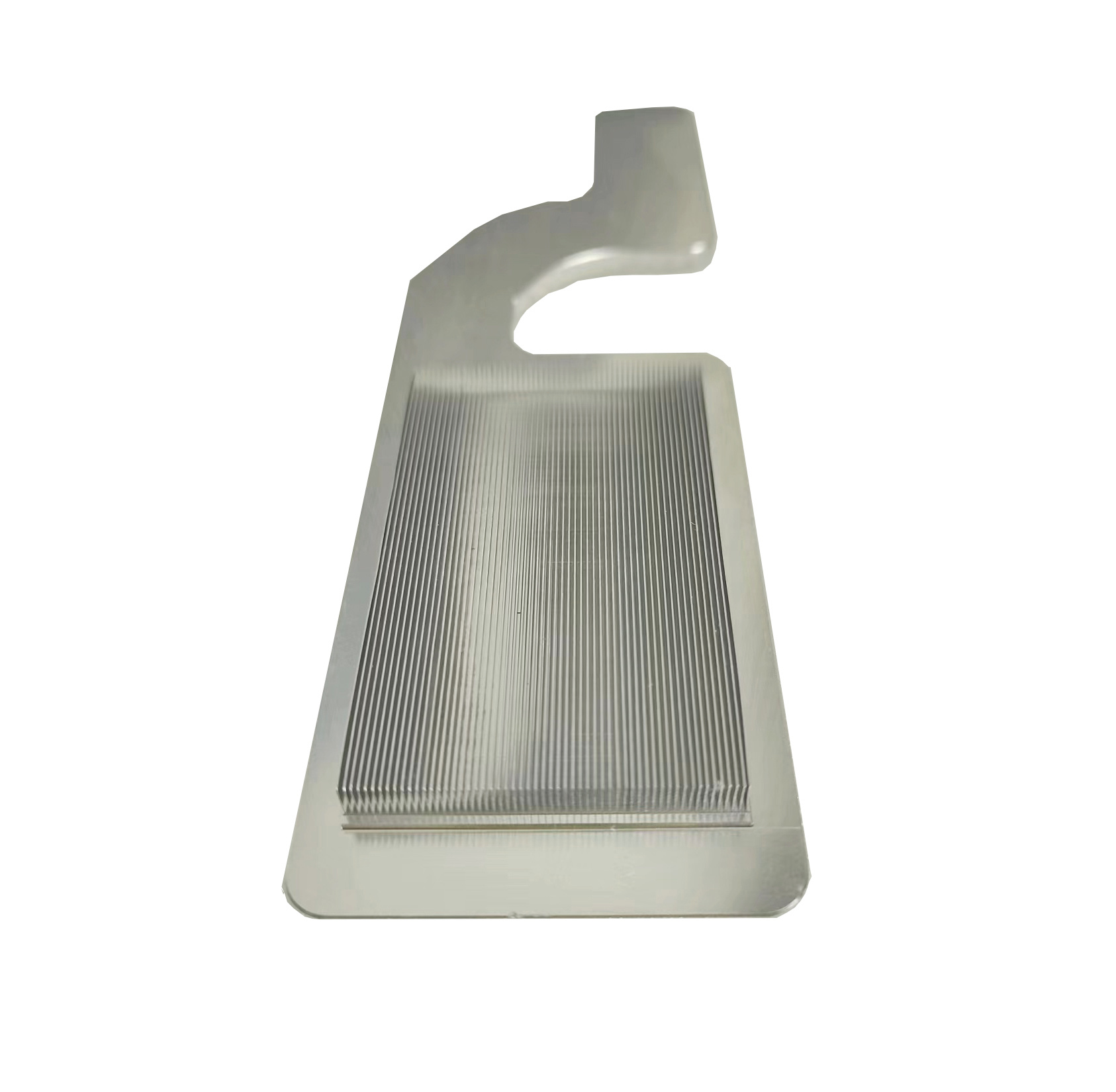

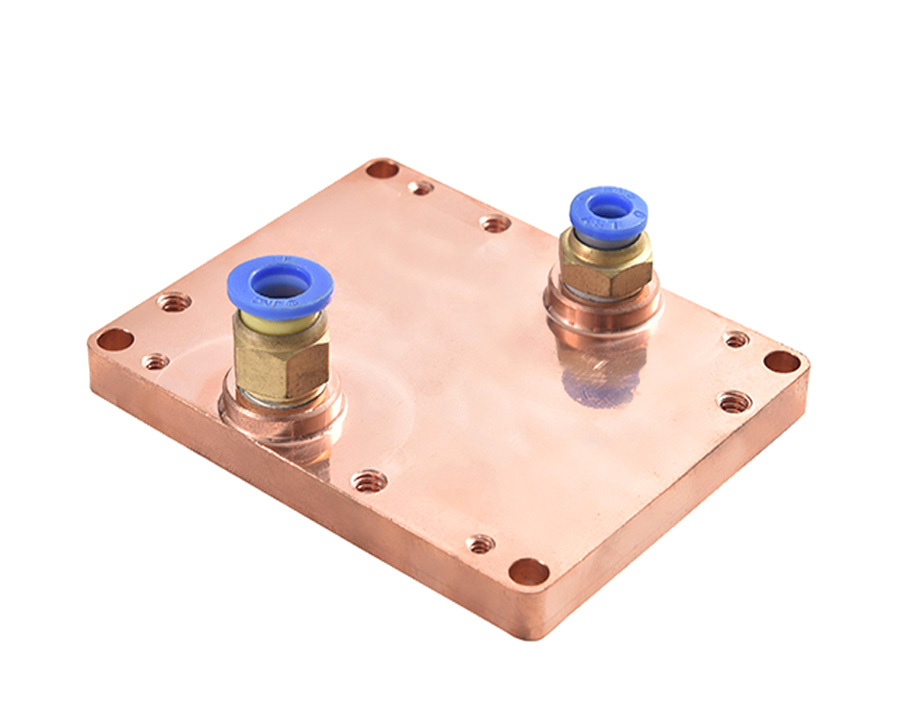

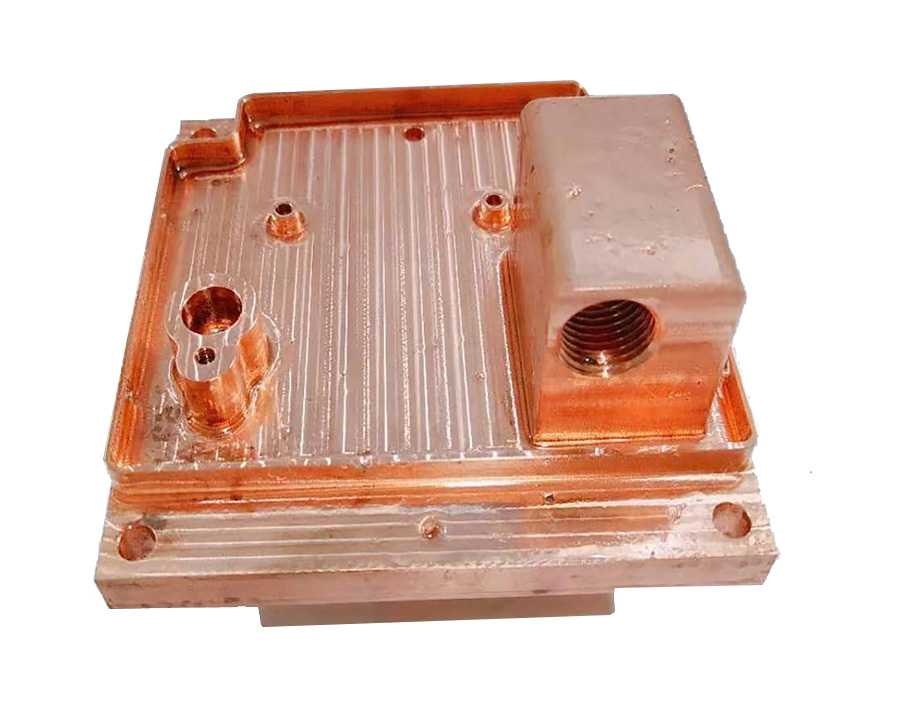

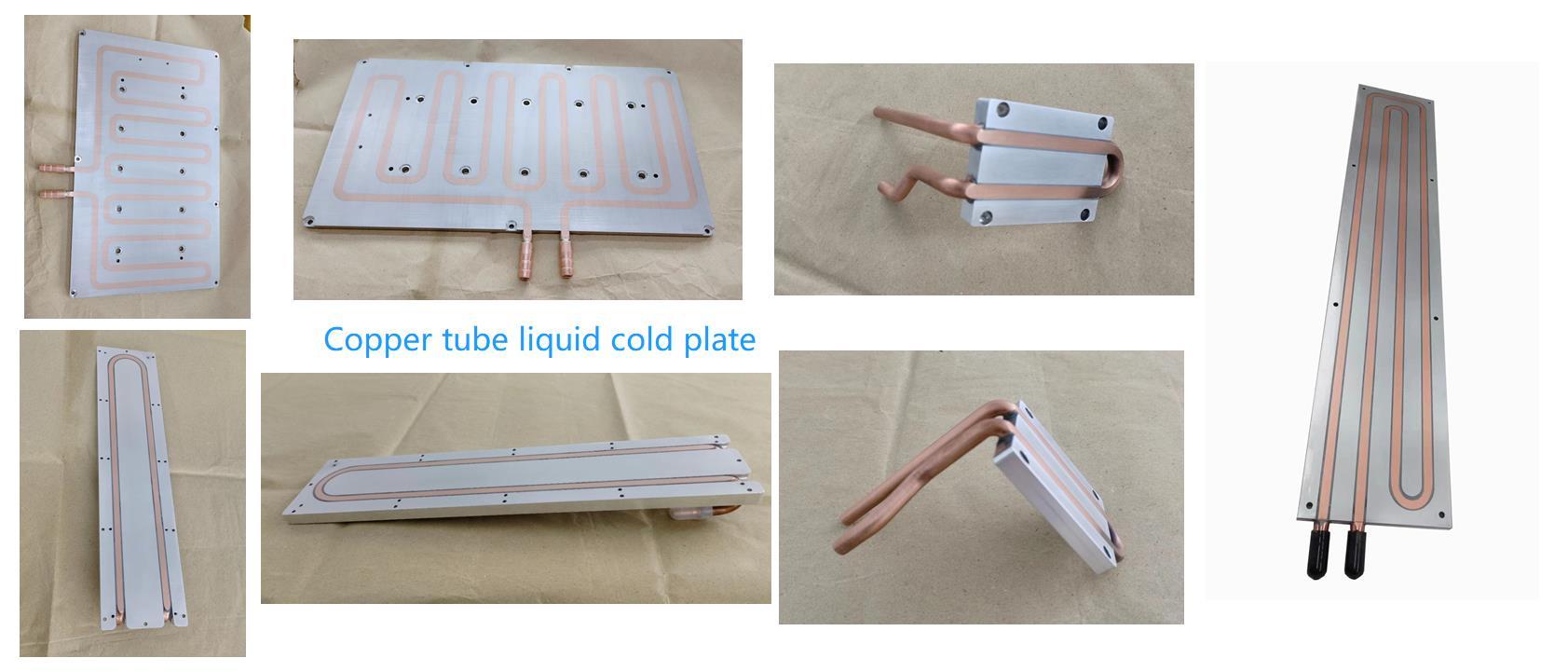

copper base embedded copper tube liquid cold plate

Contact Us

Classification