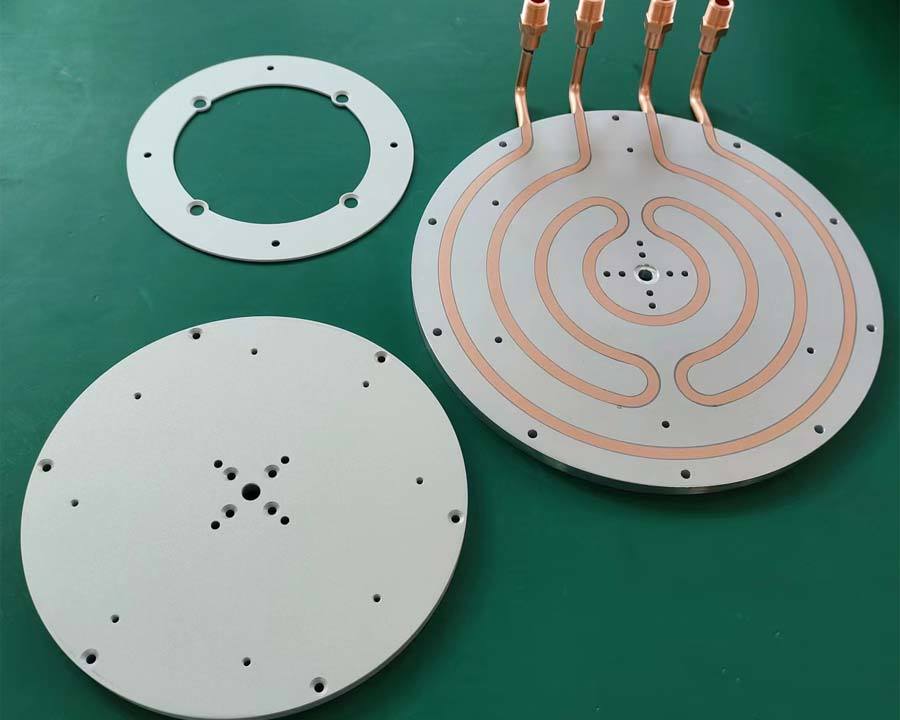

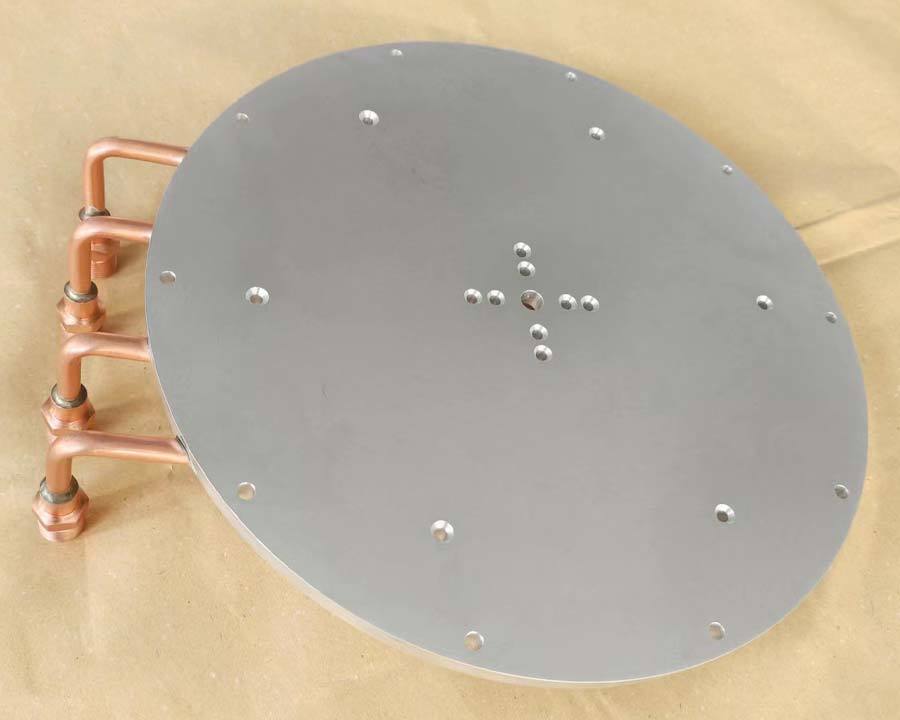

The advantages of double flow channel of copper tube liquid cold plate apply for Thermostat thermal circle or Constant temperature thermal management system.

1. Enhanced Heat Exchange Efficiency for the high power electronic components

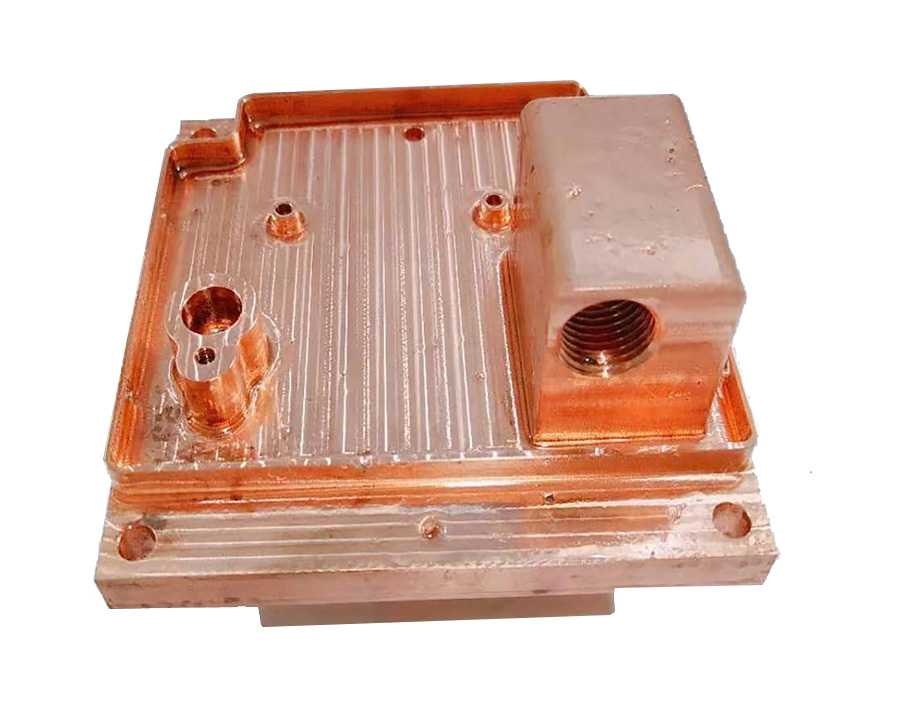

- Larger Heat Transfer Area: The double-flow-channel design increases the contact area between the copper tube and the coolant (such as water or refrigerant), allowing more heat to be absorbed and transferred in unit time.

- Optimized Flow Dynamics for the channel of cold plate: The parallel or series arrangement of dual channels can adjust the flow rate and turbulence of the coolant, reducing boundary layer thermal resistance and improving convective heat transfer coefficient. For example, in high-power electronic devices, the dual-channel structure can quickly carry away heat generated by hotspots.

- Uniform Temperature Distribution: Compared with single-channel designs, dual channels can balance heat transfer in different regions, avoiding local overheating and making the temperature field of the system more uniform. This is critical for applications requiring strict constant temperature control (e.g., precision instruments or battery thermal management).

2. High Reliability and Stability

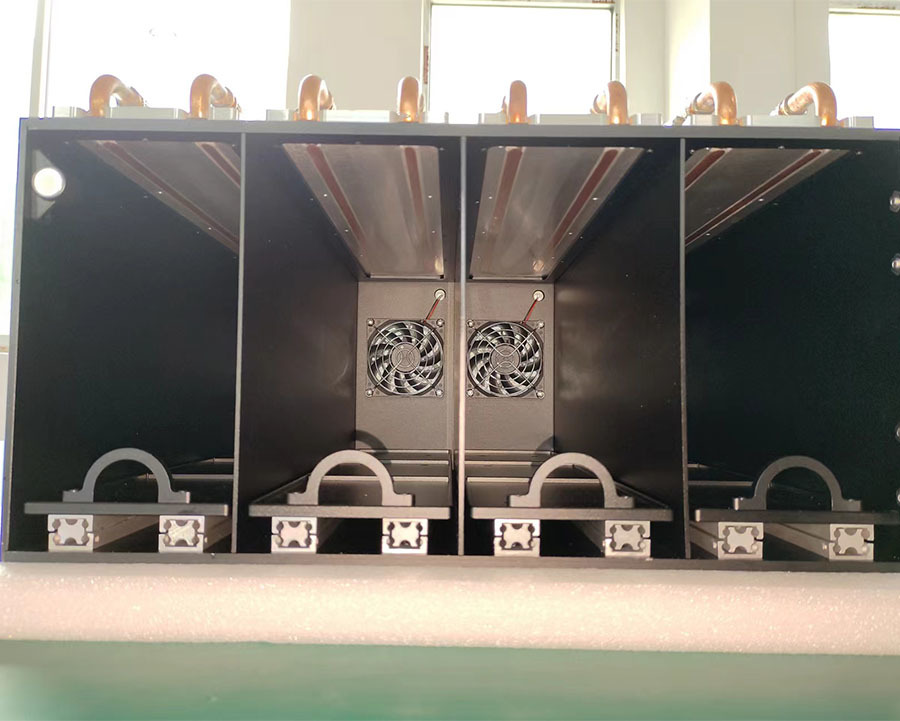

- Redundant Flow Path: The dual-channel structure provides a backup flow path. If partial blockage or failure occurs in one channel, the other channel can still maintain basic heat dissipation capabilities, improving the fault tolerance of the cooling system.

- Reduced Thermal Stress: The symmetrical design of dual channels helps to balance the thermal expansion and contraction forces of the copper tube, reducing structural deformation or fatigue damage caused by thermal stress and extending the service life of the liquid cold plate.

- Stable Flow Control: In the thermostat system, dual channels can independently or coordinately control the flow rate and temperature of the coolant (e.g., one channel for heat absorption and the other for heat dissipation), enabling more precise regulation of the thermal cycle and maintaining the stability of the constant temperature environment.

3. Flexible System Integration

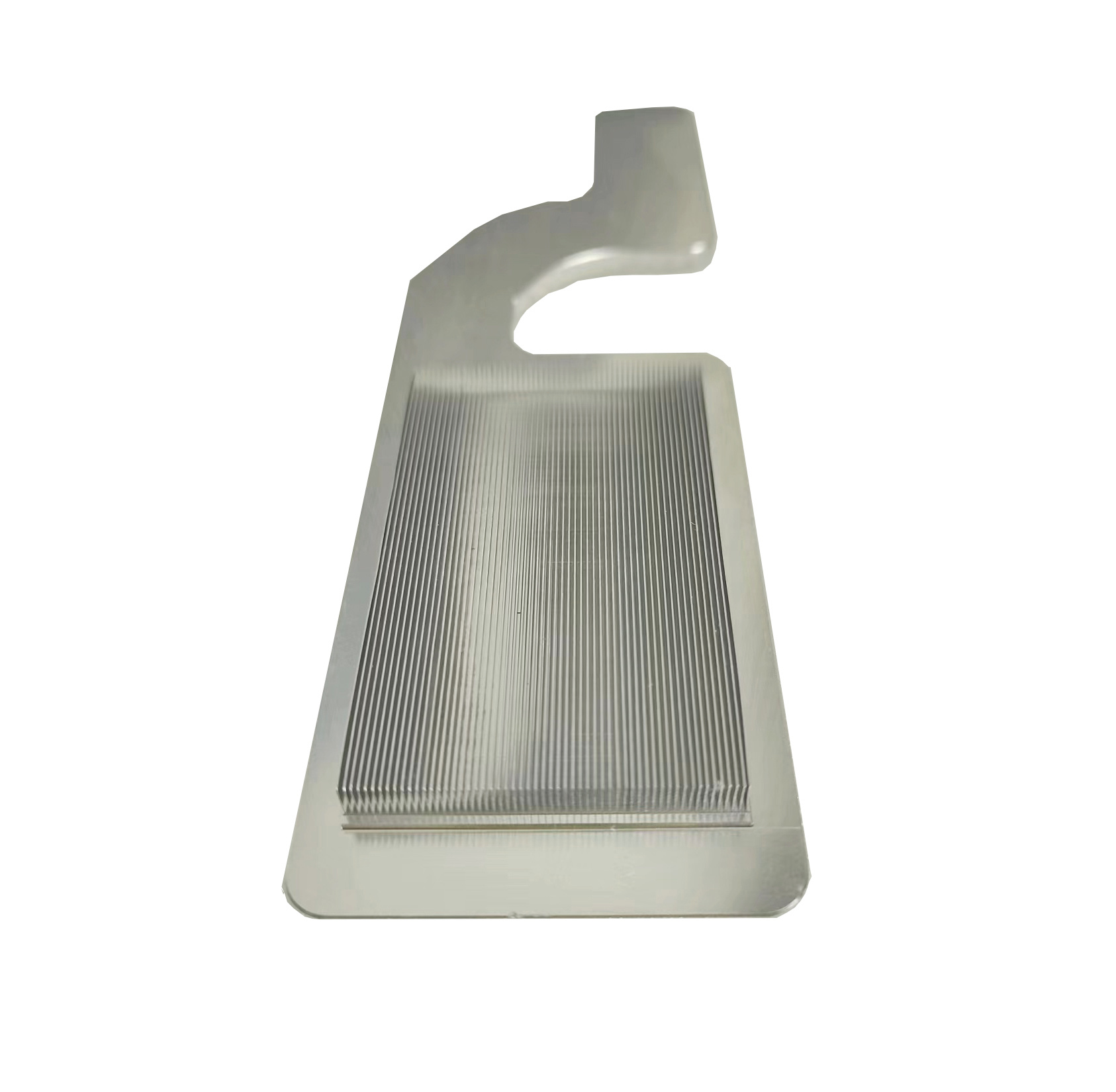

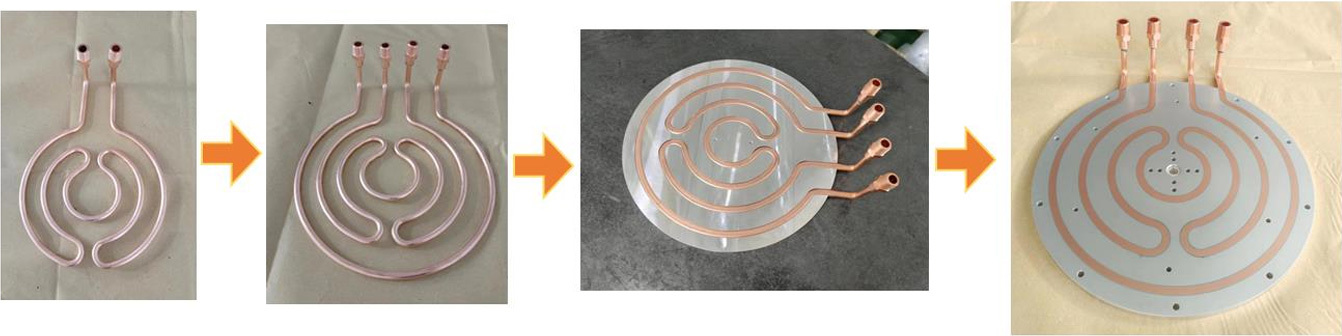

- Diversified Layout Options: The dual-channel design can be flexibly arranged according to the spatial constraints and heat dissipation requirements of the cooling system (e.g., serpentine, radial, or split layouts), adapting to complex installation scenarios (e.g., compact electronic enclosures or curved surfaces of mechanical components).

- Multi-Source Heat Management: Dual channels can separately manage heat from different heat sources (e.g., power modules and signal processing units), achieving classified heat dissipation and optimizing overall energy efficiency. For example, in data center server clusters, different channels can be allocated to cool high-load and low-load components respectively.

- Easy to Expand or Modify: Based on the dual-channel architecture, the system can be upgraded by adding parallel channels or adjusting pipeline connections in the later stage without major changes to the original structure, improving scalability of liquid cooling system.

|  |

4. Energy Saving and Low Noise

- Precise Flow Regulation: By controlling the on-off or flow rate of dual channelsof the cold plate, the system can operate in a low-power state under light loads, reducing pump power consumption and achieving energy saving. For example, only one channel is activated during low-load operation, and both channels are turned on when the load increases.

- Reduced Flow Velocity: Under the same total flow rate, the dual-channel design can reduce the flow velocity of the single-channel, thereby lowering fluid friction noise and mechanical vibration caused by the pump. This is particularly important for noise-sensitive environments (e.g., medical equipment or laboratory instruments).

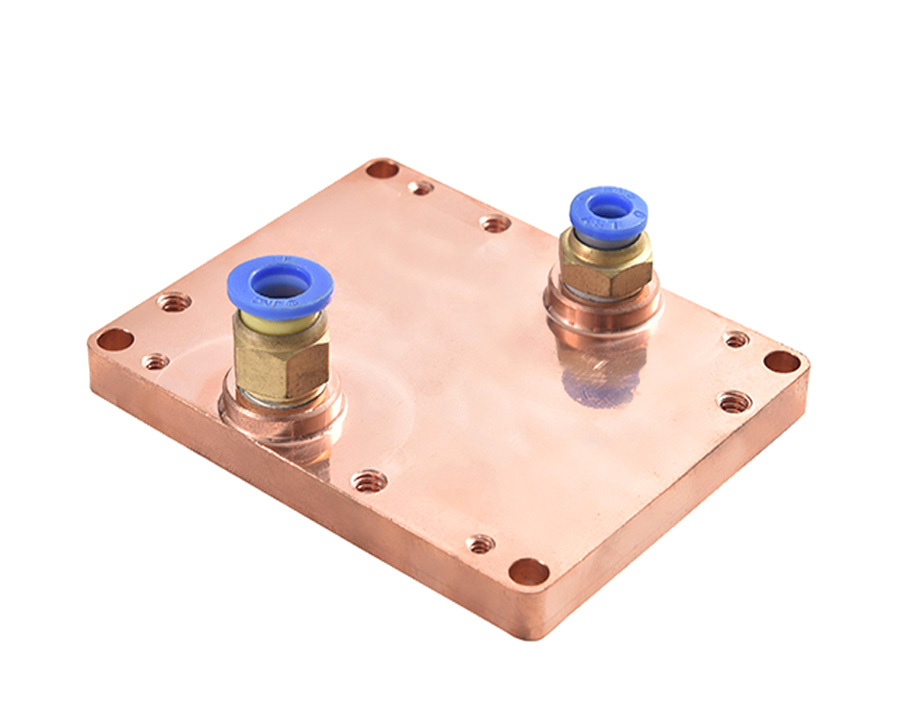

5. Material and Structural Advantages of Copper tube cold plate

- Excellent Thermal Conductivity: Copper has high thermal conductivity (401 W/m·K), which can quickly conduct heat from the heat source to the coolant, enhancing the overall heat dissipation performance of the cold plate.

- Corrosion Resistance and Compatibility: Copper has good chemical stability and is compatible with most coolants (e.g., deionized water, ethylene glycol solutions), reducing the risk of pipeline corrosion and leakage and ensuring the long-term reliable operation of the system.

- Processability: Copper is easy to form and weld, enabling the dual-channel structure to be manufactured with high precision (e.g., through brazing or extrusion processes), ensuring the consistency and tightness of the flow channel.

|  |

In summary, the double-flow-channel copper tube liquid cold plate optimizes heat transfer efficiency, reliability, and adaptability through structural innovation, making it an ideal choice for high-precision thermostat and constant temperature thermal management systems. Its advantages are particularly prominent in scenarios requiring high heat dissipation efficiency, stable temperature control, and long-term reliable operation.

Thermostat liquid cooling copper tube cold plate

Contact Us

Classification