The advantages of FSW liquid cold plate used for high power laser liquid cooling system

1. Excellent Thermal Conductivity and Uniform Cooling

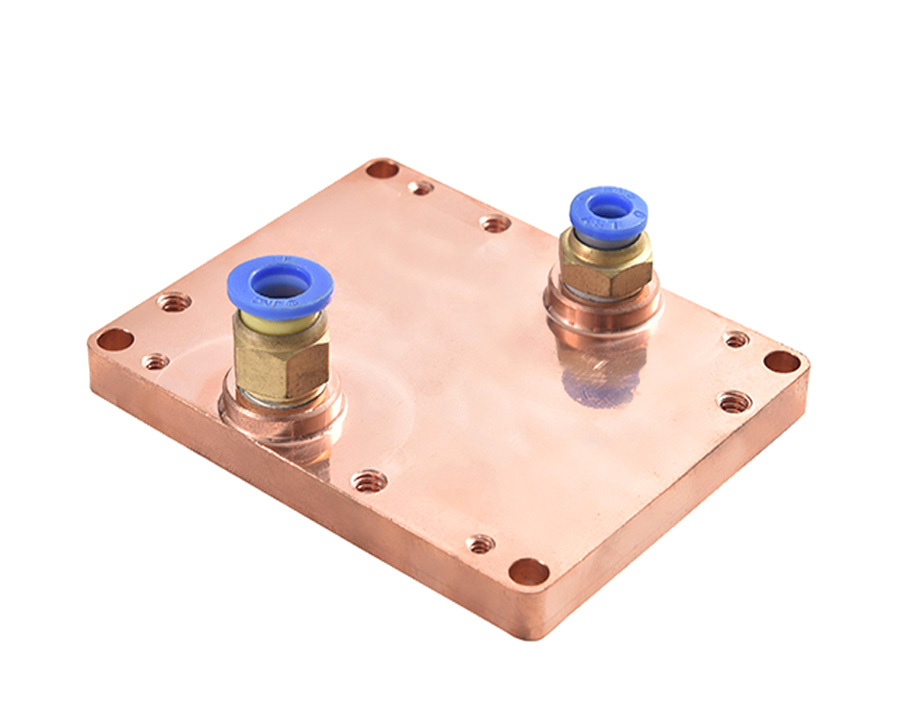

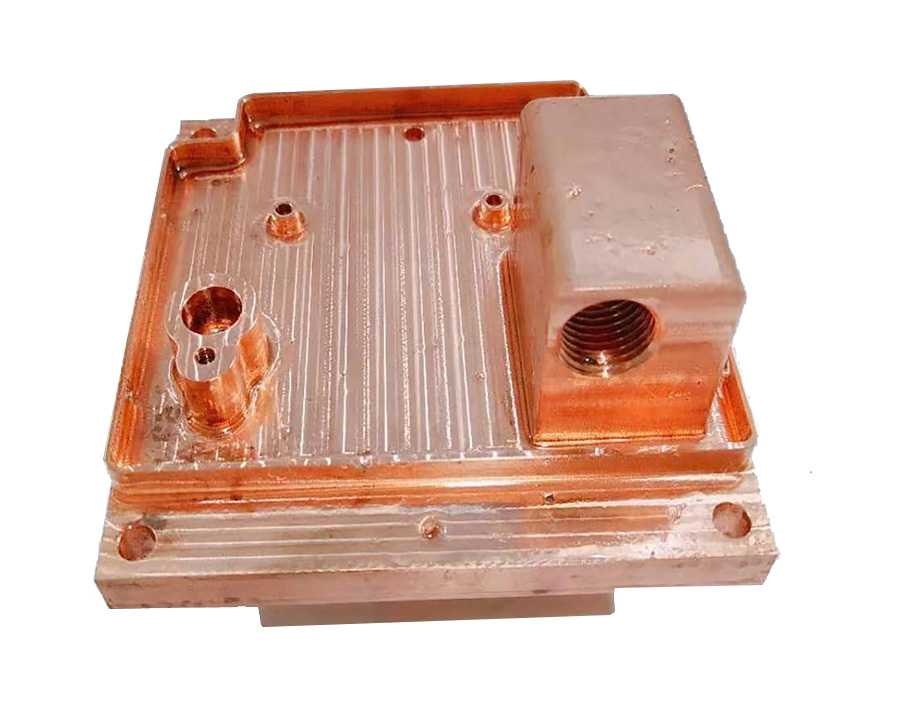

- Efficient Heat Dissipation: FSW technology creates a solid-state weld without melting the base material, preserving the thermal conductivity of the metal (e.g., aluminum or copper). This ensures rapid heat transfer from high-power laser components to the coolant.

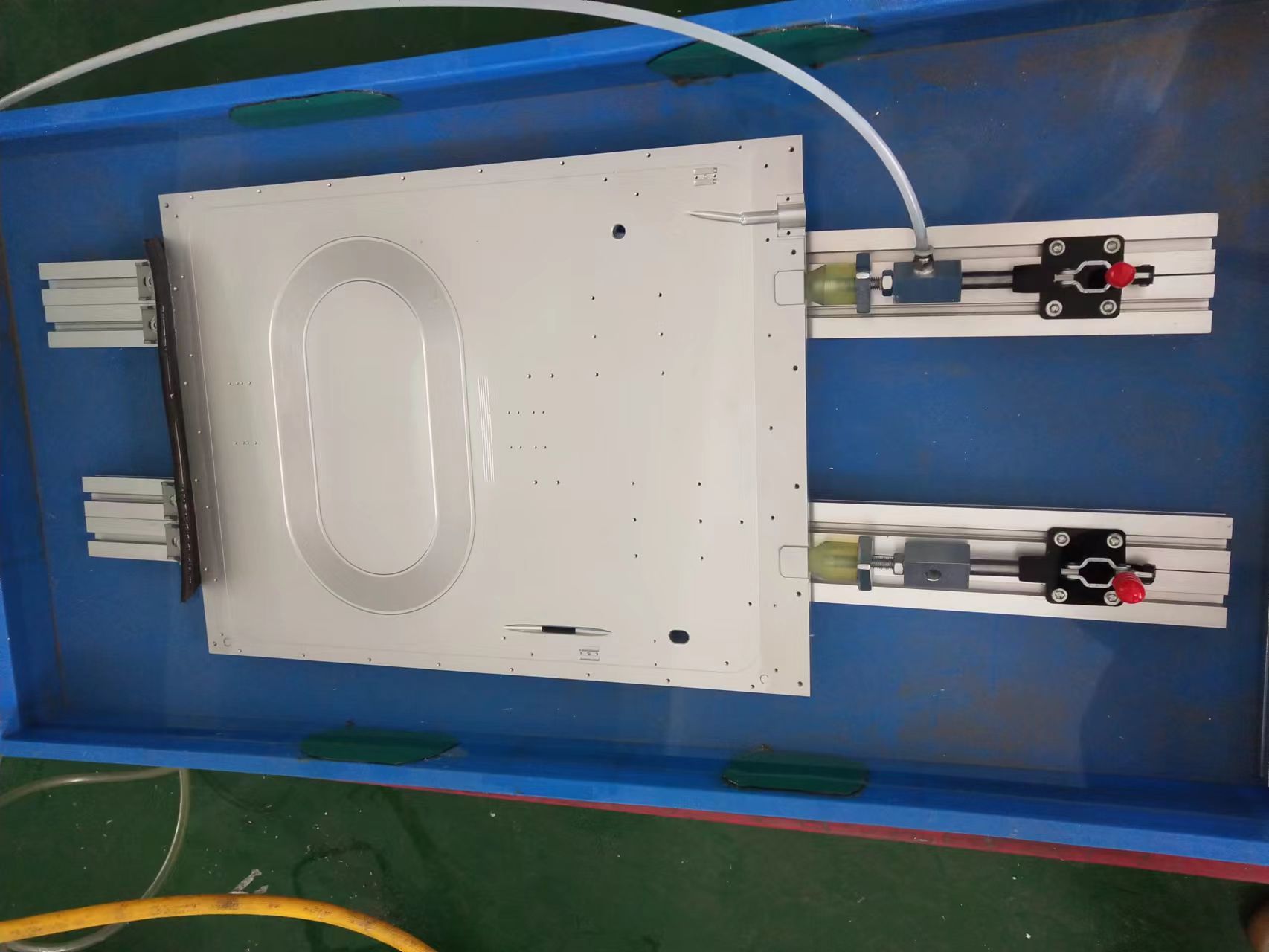

- Uniform Temperature Distribution: The seamless internal channel structure formed by FSW minimizes thermal resistance and hotspots, providing consistent cooling across the entire cold plate surface. This is critical for maintaining laser beam stability and performance.

2. High Structural Strength and Reliability

- Leak-Proof Design: FSW produces a dense, defect-free weld with high joint strength, reducing the risk of coolant leakage compared to traditional brazing or soldering methods. This is essential for avoiding system failures in high-power applications.

- Pressure Resistance: The robust welded structure can withstand high coolant pressures (e.g., in forced-flow systems), ensuring reliable operation under demanding conditions.

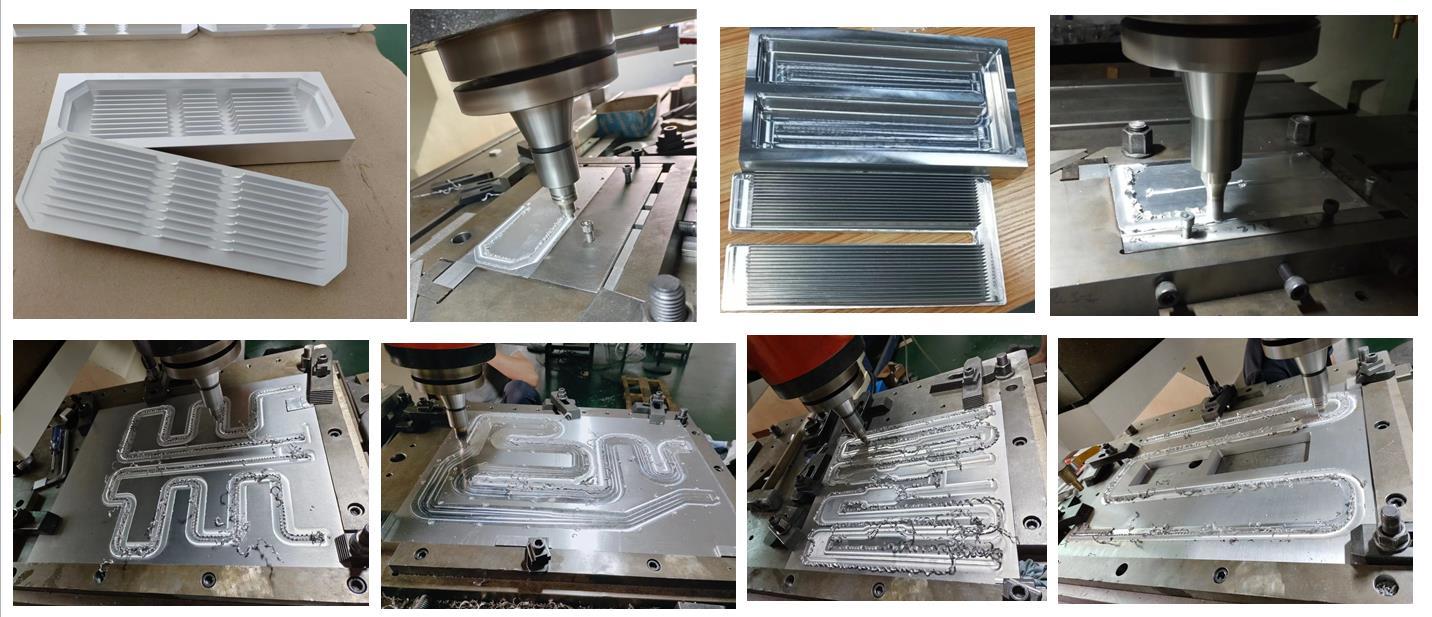

3. Complex Channel Design Flexibility

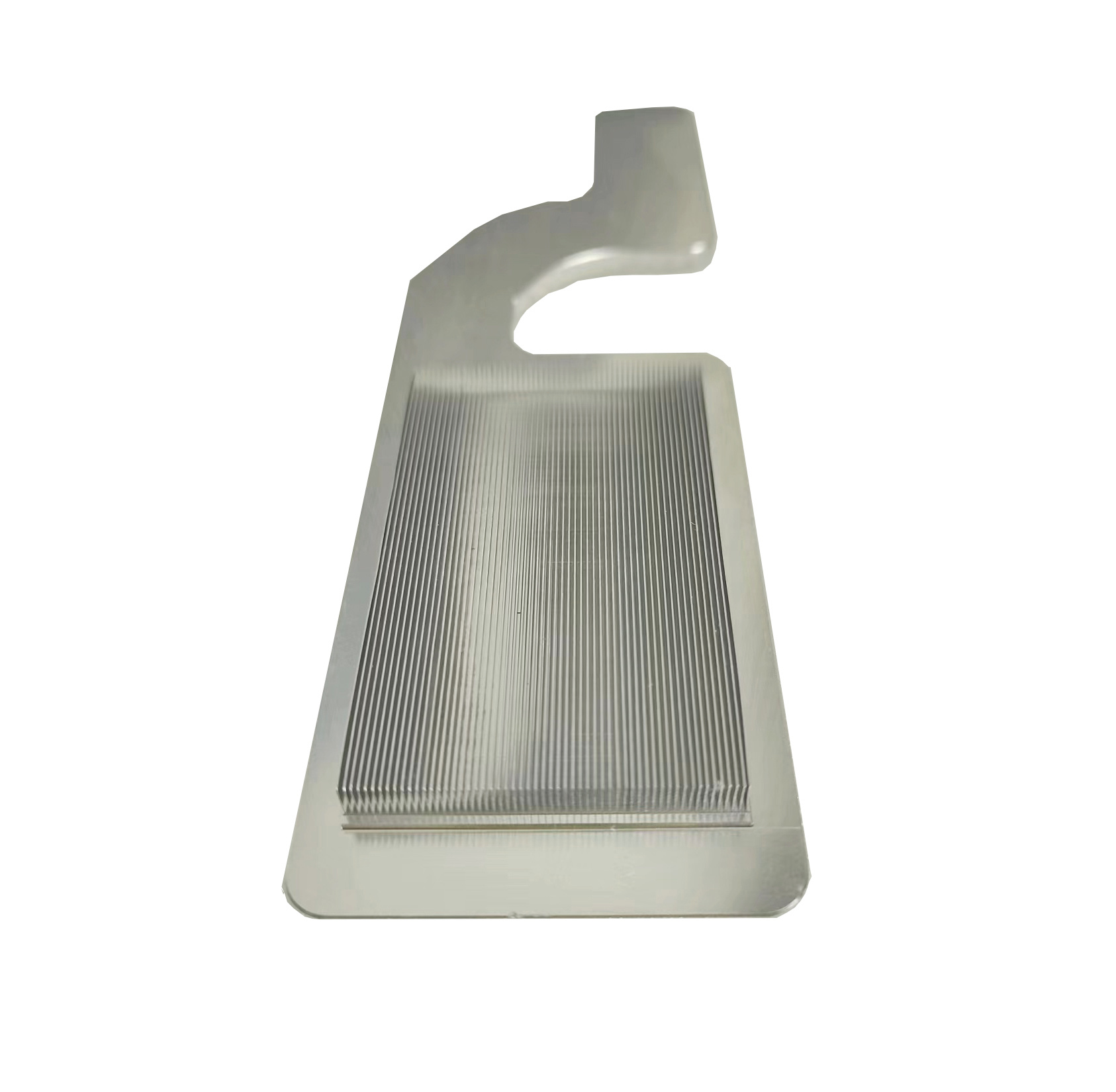

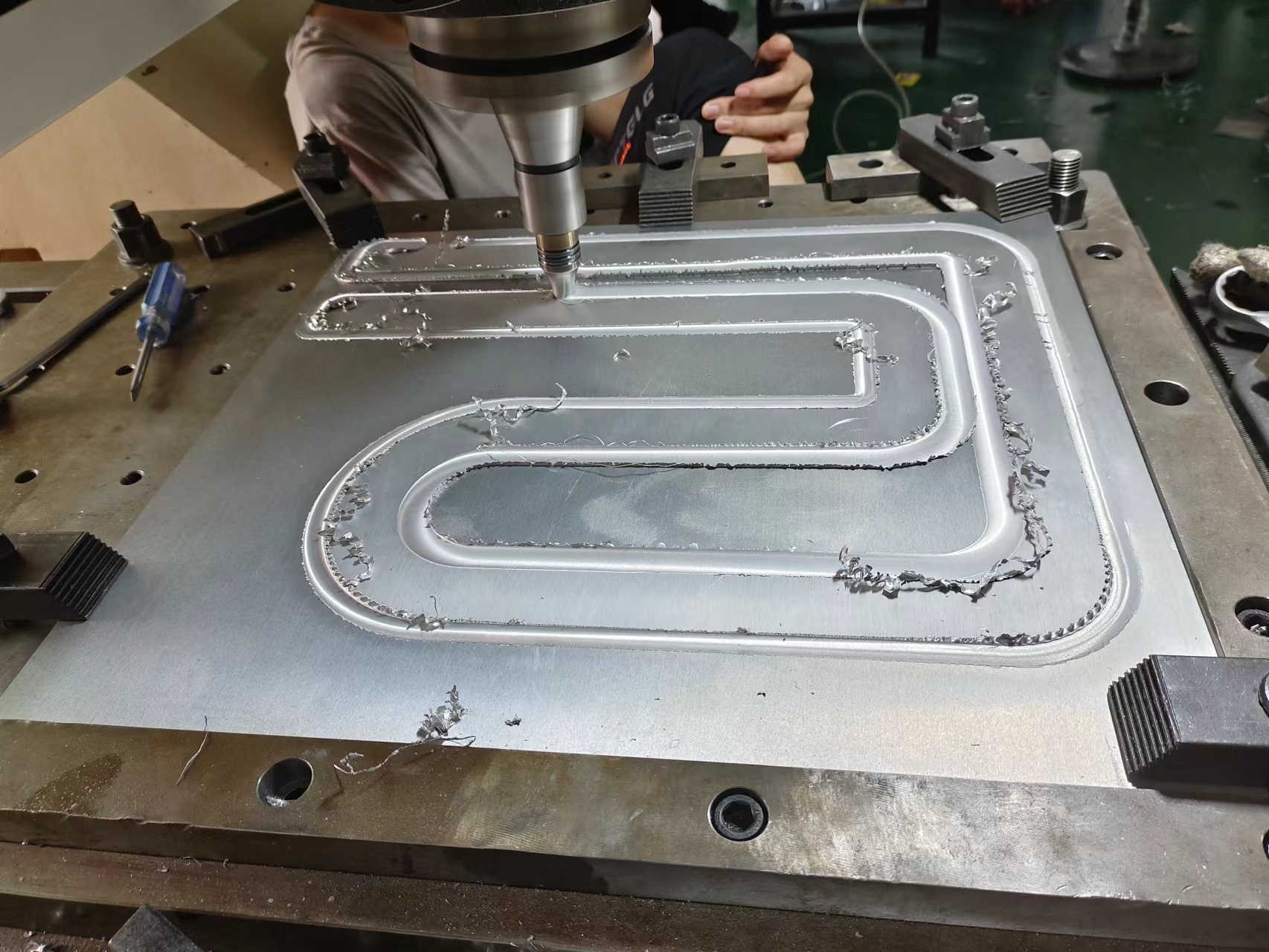

- Customizable Flow Paths: FSW allows for the fabrication of intricate internal channels (e.g., serpentine, pin-fin, or spiral designs) to optimize coolant flow and heat exchange efficiency. This flexibility is vital for adapting to the unique heat dissipation requirements of different laser systems.

- Thin-Wall Construction: FSW enables the creation of thin-wall channels with high aspect ratios, maximizing heat transfer surface area while minimizing coolant volume and system weight.

4. Material Compatibility and Corrosion Resistance

- Diverse Material Options: FSW works well with high-thermal-conductivity materials like aluminum alloys (for lightweight systems) and copper (for extreme heat loads). Welds between dissimilar metals (e.g., aluminum-copper) are also feasible with proper process optimization.

- Corrosion Resistance: The solid-state welding process does not introduce flux residues or alter the base material’s corrosion-resistant properties, ensuring long-term reliability in harsh environments.

5. Scalability and Cost Efficiency

- Industrial Scalability: FSW is a repeatable, automated process suitable for mass production, ensuring consistent quality across multiple cold plates.

- Reduced Assembly Costs: Compared to bonded or bolted cold plates, FSW eliminates the need for additional adhesives, fasteners, or secondary machining, reducing manufacturing time and costs.

6. Low Maintenance and Longevity

- Durable Construction: The absence of fragile brazed joints or soldered interfaces reduces the likelihood of fatigue failure or delamination over time, extending the cold plate’s operational lifespan.

- Simplified Maintenance: The leak-resistant design minimizes the need for frequent inspections or repairs, improving overall system uptime.

7. Environmental and Operational Safety

- Lead-Free Process: FSW is a green manufacturing technique that does not involve hazardous materials (e.g., lead-based solders), aligning with environmental standards (e.g., RoHS).

- Stable Performance Under Thermal Cycling: The welds maintain integrity during repeated thermal expansion and contraction cycles, ensuring safe operation in high-power laser systems with fluctuating heat loads.

Applications in High-Power Laser Systems

- Industrial laser machining (e.g., cutting, welding, drilling)

- Defense-grade laser systems (e.g., directed energy weapons)

- Medical lasers (e.g., high-power surgical devices)

- Aerospace laser systems (e.g., airborne or satellite-based lasers)

High power FSW liquid cold plate for Fibre laser liquid cooling system

Contact Us

Classification

Related Products