What's the basic structure for the buried heat pipe bonded fin heat sink?

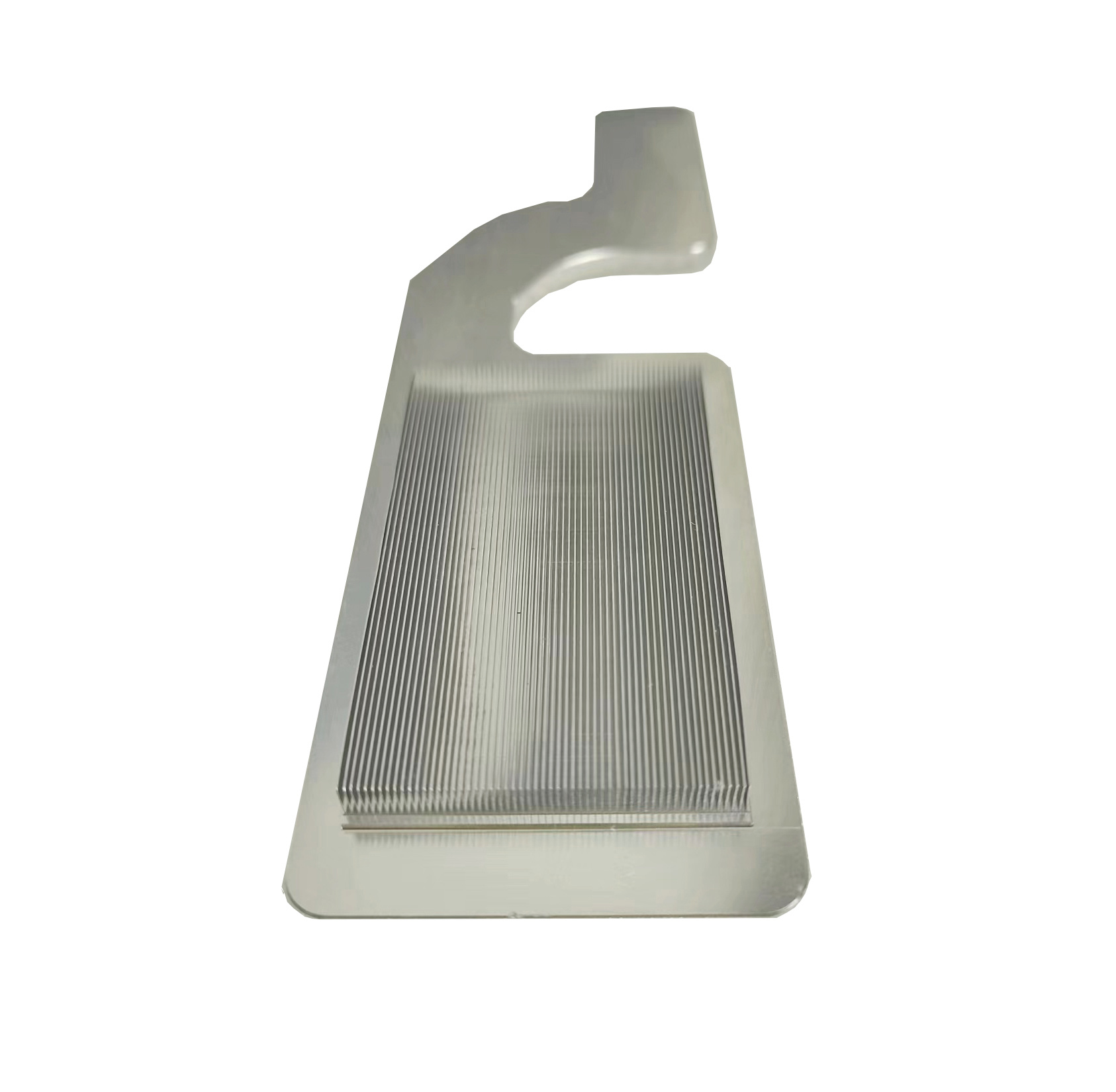

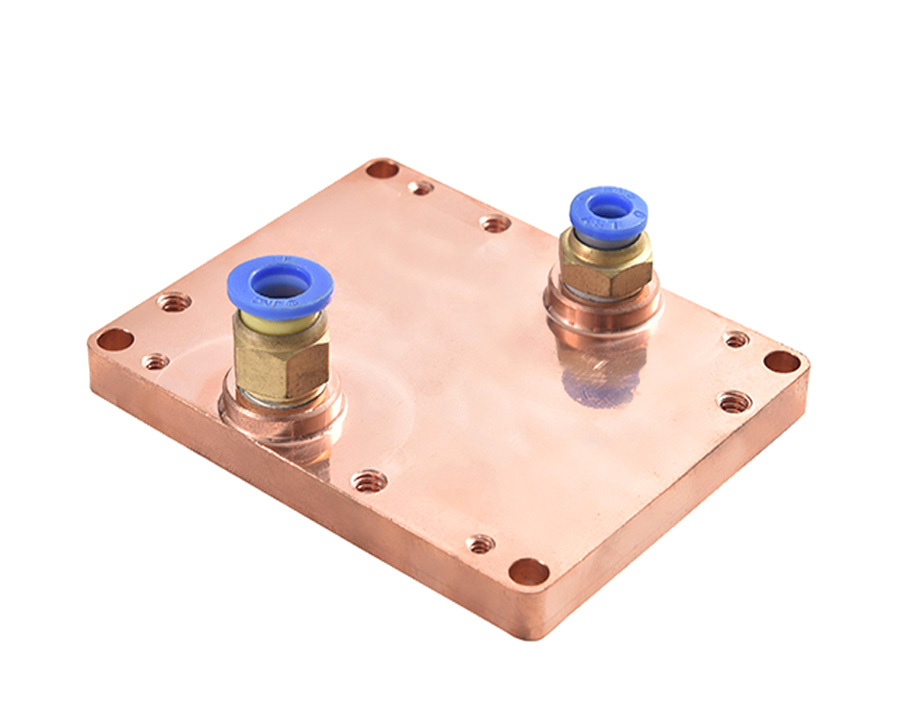

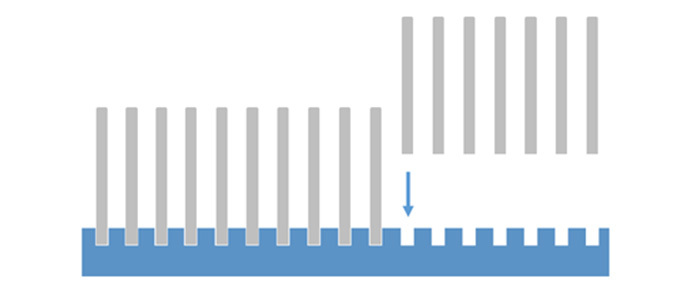

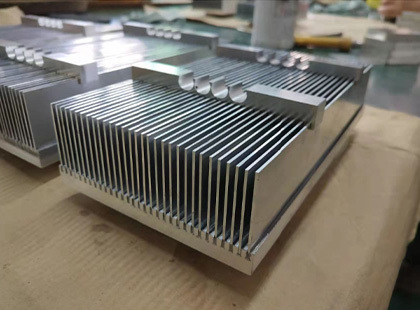

- Basic Structure: It is mainly composed of a heat pipe, a bonding fin, and a base. The heat pipe is the core component for heat transfer, usually a sealed metal tube with a working fluid inside. The bonding fins are used to increase the heat dissipation area, and they are closely bonded to the base. The base is in direct contact with the heat source to be cooled, such as electronic components.

What's the main manufacturing process to produce the a bonding fin heat sink?

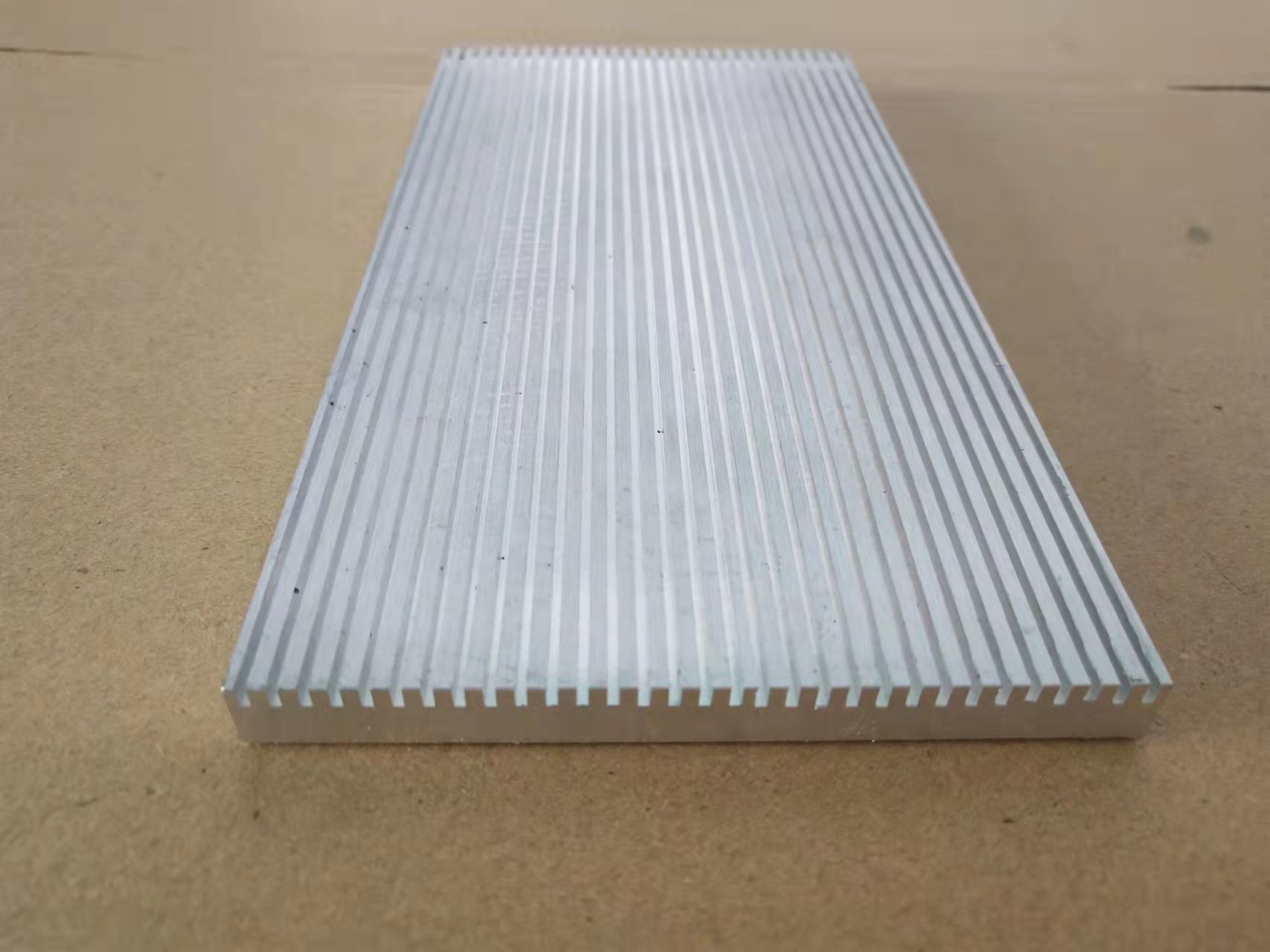

- Fin Manufacturing: The fins are typically made of aluminum or copper sheets through processes such as stamping, extrusion, laser cutting. Stamping fins is suitable for mass production of simple-shaped fins; extrusion can produce fins with more complex shapes and higher precision; But these two options of stamping fins and extrusion the fins both need the tooling charge. So if the quantity is small, Usually use the laser cutting the fins.

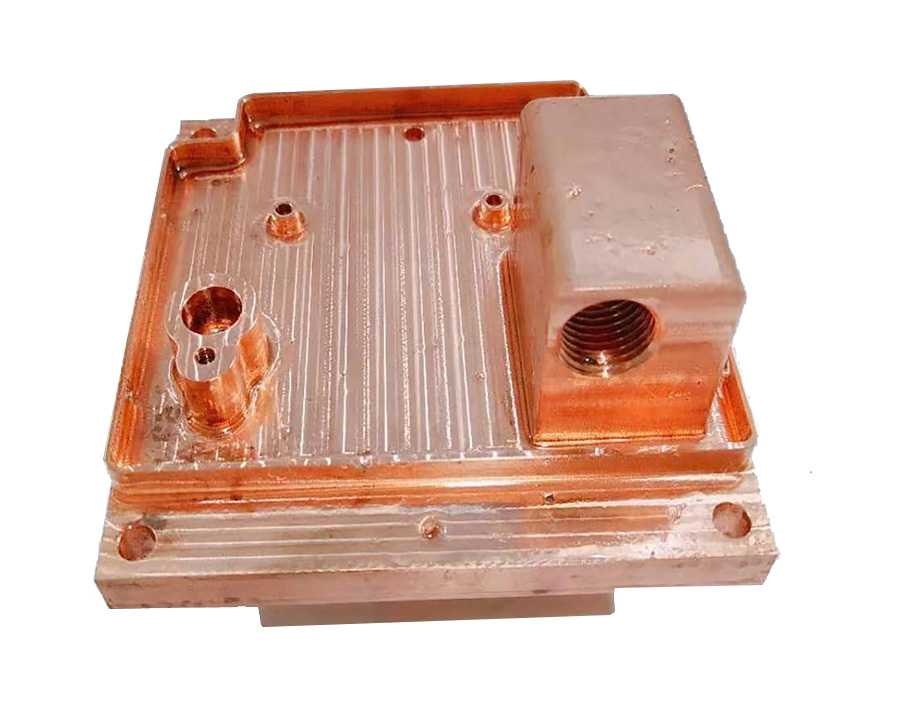

- Base Manufacturing: The fin base are used the CNC machining the fin slots if the requirement amount is not very large, Of course it can be make a extrusion tooling to extruded the base with the slots directly if there's a large demand.

- Bonding Fins Process: The bonding of the fins to the base is a crucial step. Commonly used bonding methods include thermal conductive adhesive bonding, brazing, and soldering. Thermal conductive adhesive bonding is simple and convenient, suitable for some low-power applications; brazing and soldering can achieve stronger bonding and better thermal conductivity, but the process is more complex and requires higher temperatures, Absolutely, The cost of brazing and soldering options are much higher than bonded.

What are the emmbed heat pipe bonded fin heat sink usually apply for ?

- Electronic Devices cooling: Widely used in the heat dissipation of various electronic components such as CPUs, GPUs, power amplifiers, and integrated circuits in computers, servers, game consoles, and communication equipment to ensure their stable operation.

- Automotive Electronics cooling: Applied to the heat dissipation of automotive engine control units, power batteries, and electronic control systems to improve the reliability and lifespan of automotive electronic devices.

- Photovoltaic Power Generation cooling: Used for the heat dissipation of photovoltaic inverters and other components to enhance the conversion efficiency and stability of photovoltaic power generation systems.

- Industrial Control cooling: Applied in the heat dissipation of industrial control equipment such as programmable logic controllers (PLCs), frequency converters, and servo drives to ensure the normal operation of the equipment in harsh industrial environments.

Buried heat pipe bonded fin heat sink

Contact Us

Classification