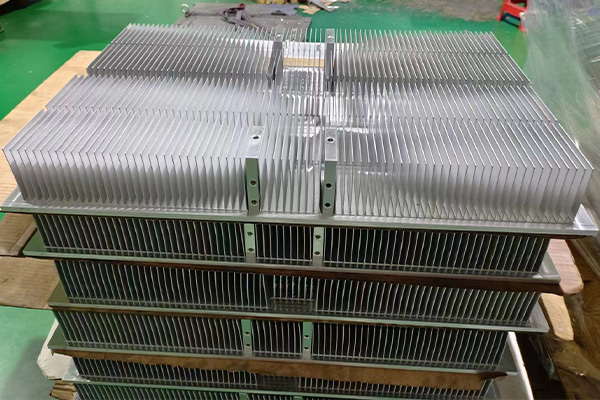

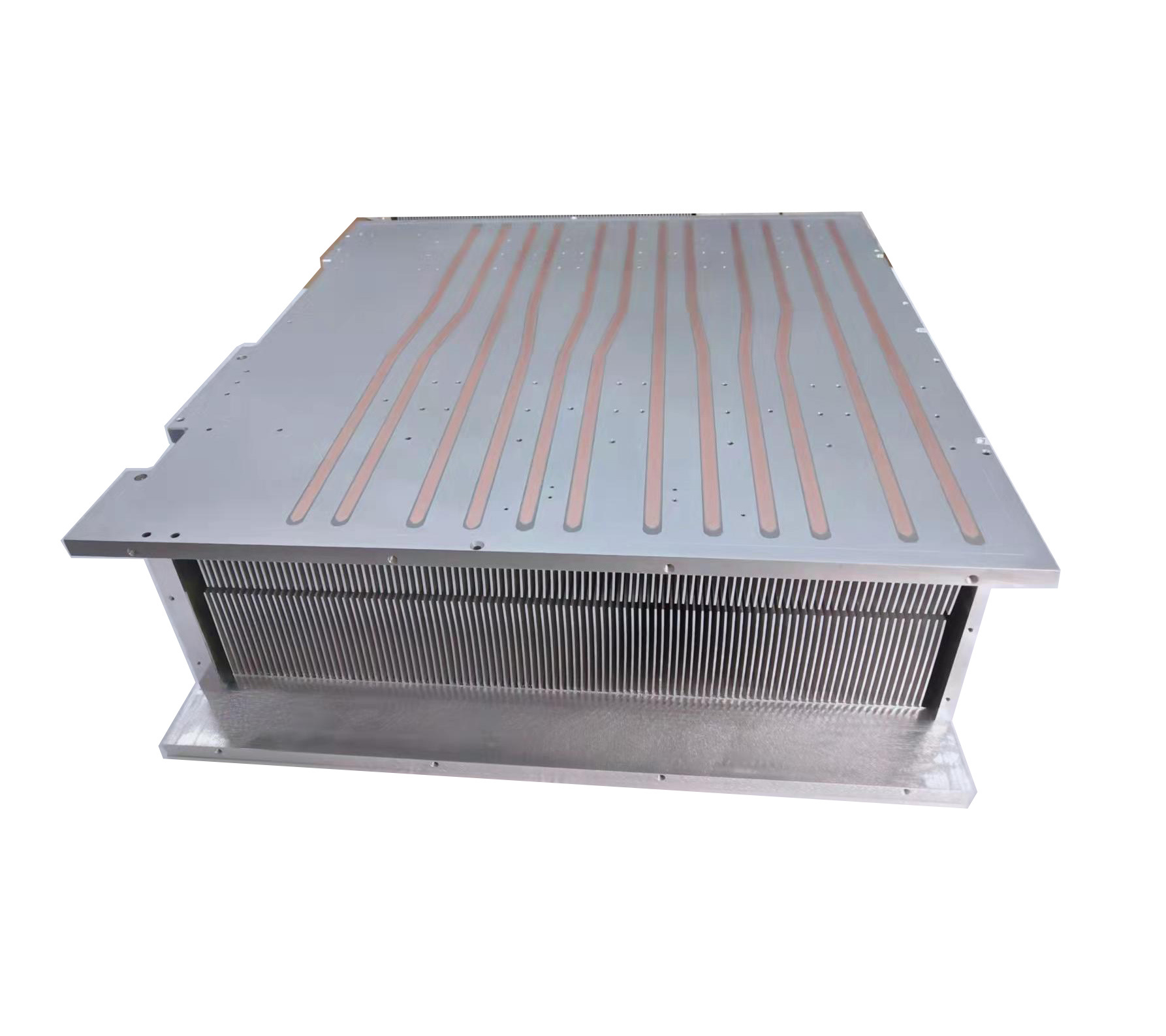

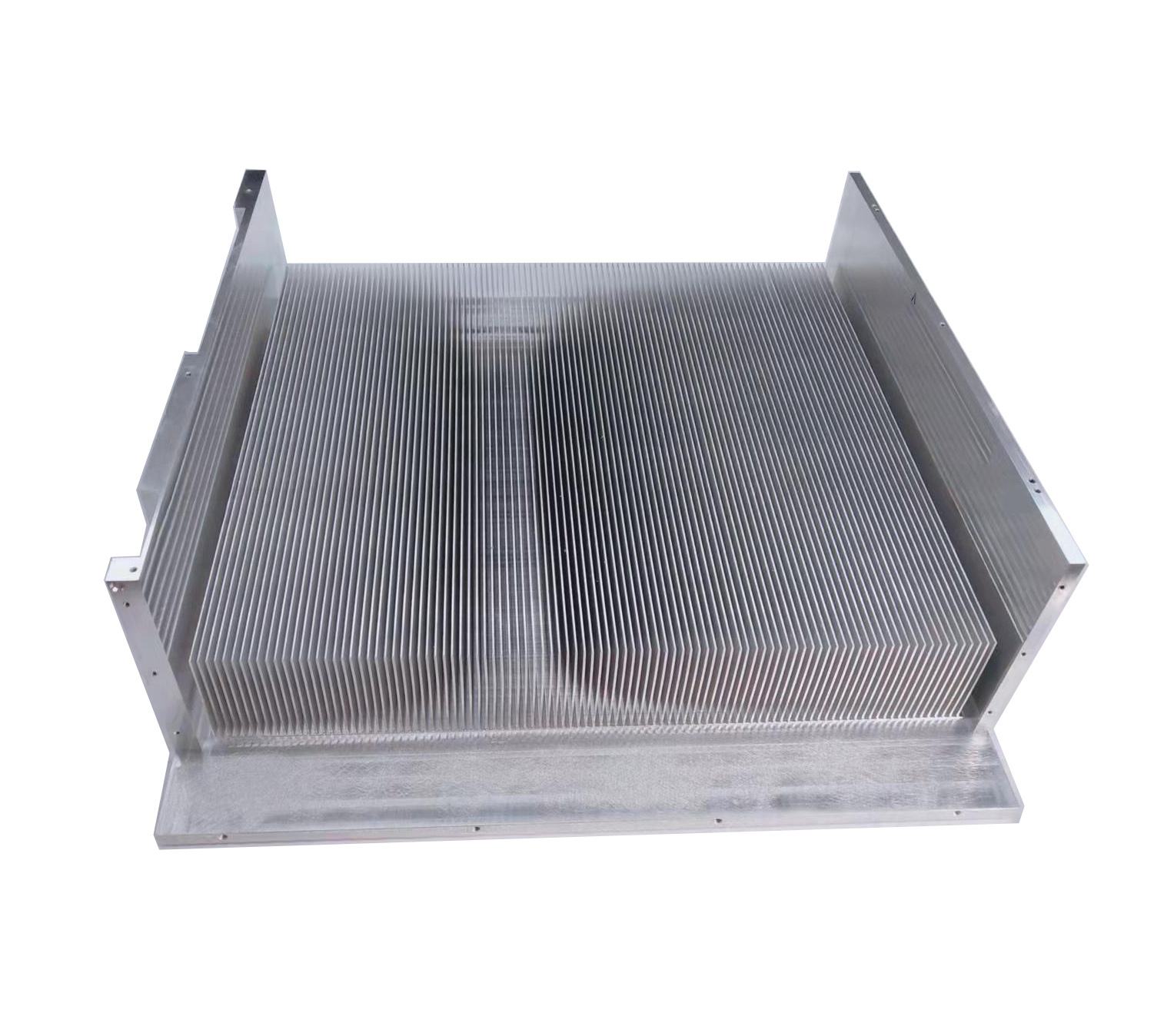

When the aluminum skived heat sink encounters a situation that the skived fin process cannot meet the structural requirements, rivet structure or friction welding can be used. What other methods can be used to make up for it?

- Bonding:

- Adhesive Bonding: Special heat - resistant adhesives can be utilized to attach fins or other components to the heat sink base. This approach is suitable for scenarios where the bonding area is large and the force applied is relatively even. For example, in some electronic device heat sinks, heat - resistant epoxy resins are often used to bond aluminum - alloy - made fins to the base plate. The advantages of this method include good sealing, the ability to bond components of different materials, and low manufacturing costs. However, its drawbacks are that the adhesive has limited heat resistance and durability, and long - term use at high temperatures may lead to a decrease in bonding strength.

- Diffusion Bonding: This is a high - temperature and high - pressure process that causes the surfaces of two metal components to diffuse and bond at the atomic level. It is suitable for bonding aluminum alloys with high - precision requirements. For instance, in the aerospace field, when manufacturing heat sinks for some high - performance electronic equipment, diffusion bonding is used to bond aluminum alloy components to ensure a reliable connection and excellent heat - transfer performance. The benefits of this method are its strong bonding strength and excellent heat - conduction properties. Nevertheless, it requires high - temperature and high - pressure equipment, resulting in high manufacturing costs and low efficiency.

|  |

- Welding:

- Tungsten Inert Gas (TIG) Welding: TIG welding is a commonly used arc - welding method that uses a tungsten electrode to generate an arc to melt the welding material and the base metal, achieving a welded joint. It is suitable for welding aluminum alloys with high - quality requirements. For example, in the production of some high - end audio equipment heat sinks, TIG welding is used to ensure a beautiful welding appearance and good heat - dissipation performance. The advantages of TIG welding include high welding quality, small heat - affected zone, and good weld forming. However, its disadvantage is that the welding speed is slow, and the efficiency is relatively low.

- Laser Welding: Laser welding utilizes a high - energy - density laser beam to irradiate the joint of the workpiece, causing the material to melt and solidify to form a welded joint. It is suitable for occasions where high - precision and high - speed welding of aluminum alloys are required. For example, in the manufacturing of heat sinks for some miniature electronic devices, laser welding is employed to achieve precise connection of fins and the base plate. The advantages of laser welding are high welding speed, small heat - affected zone, high precision, and good repeatability. However, the equipment is expensive, and the welding penetration depth is limited.

|  |

- Mechanical Connection:

- Snap - Fit Connection: The snap - fit structure is designed on the heat sink, and the fins or other components are connected by snapping. This method is suitable for occasions where the connection needs to be disassembled and assembled frequently. For example, in some computer - case heat sinks, snap - fit connections are used to facilitate the replacement and cleaning of fins. The advantages of this method are convenient installation and disassembly, no additional tools are required, and the connection is relatively firm. However, its disadvantage is that the snap - fit structure has certain limitations on the shape and size of components, and the connection strength may be affected in high - vibration environments.

|  |

- Screw Connection: Screws are used to connect the fins and the base plate of the heat sink. This method is suitable for scenarios where the connection strength needs to be high. For example, in the heat sinks of some industrial equipment, screw connections are often used to ensure the stability of the fins. The advantages of screw connections are high connection strength, reliability, and easy disassembly and assembly for maintenance. However, the disadvantage is that the installation and disassembly process is relatively time - consuming, and the presence of screws may affect the appearance and heat - dissipation performance of the heat sink.

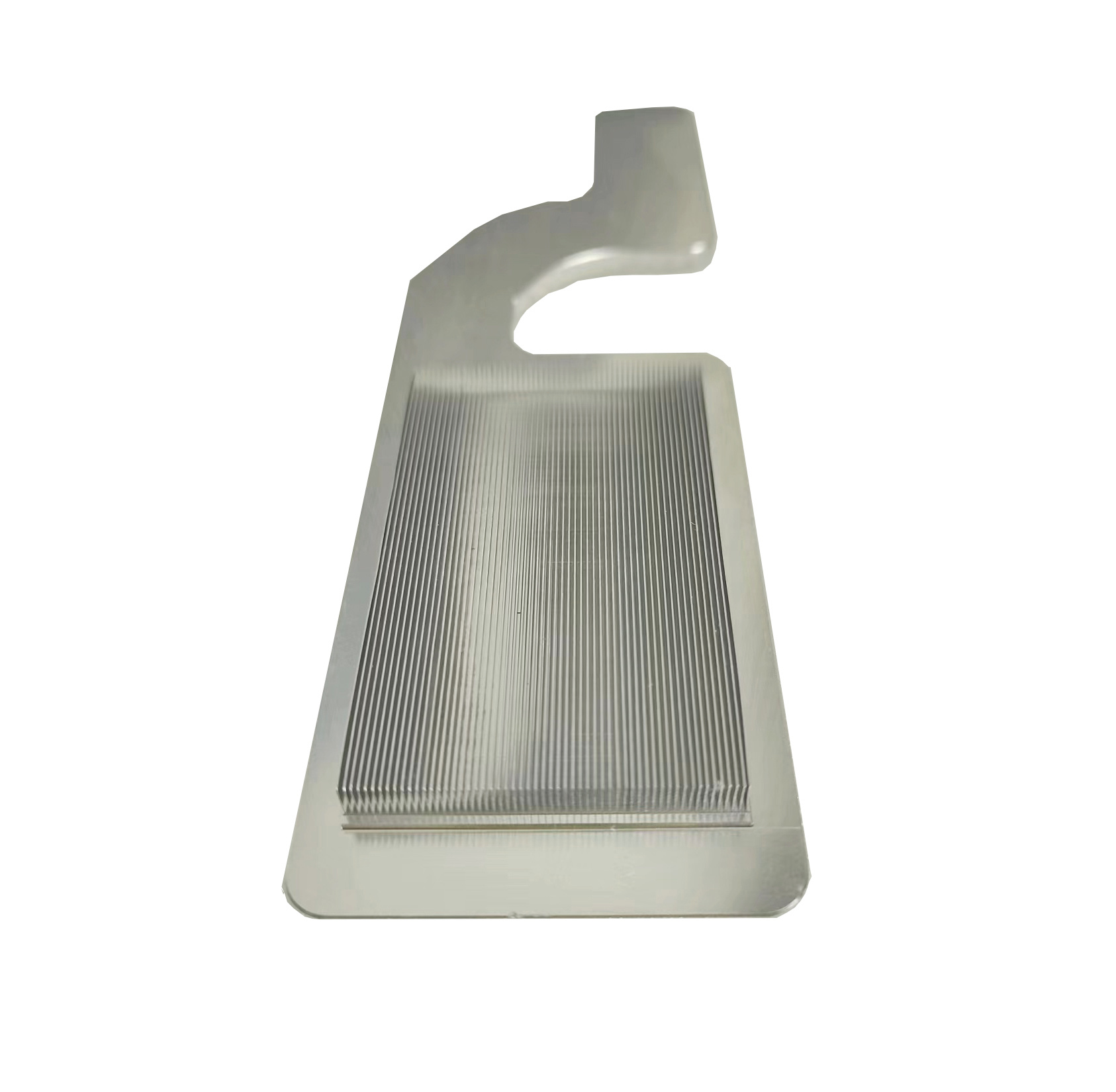

Electronic heatsink---Aluminum skived heat sink

Contact Us

Classification