What is the key point to manufacturing Aluminum FSW liquid cold plate for fiber laser liquid cooling?

How to select the material for the FSW process good for liquid cold plate ?

- Base Material:

- Use high-purity aluminum alloys (e.g., AL6061, AL6063) with excellent thermal conductivity (≈167–205 W/m·K) and weldability.

- Ensure the material has uniform grain structure and low impurity content to avoid defects during FSW.

- Surface Treatment:

- Pre-clean the aluminum surfaces to remove oxides (e.g., using degreasing agents or mechanical abrasion) to improve weld quality.

How to optimaze Friction Stir Welding (FSW) Process for the cold plate?

(1) Welding Tool Design

- Pin Profile: The tool’s pin shape (e.g., threaded, triangular, or cylindrical) affects heat generation and material flow. A longer pin may penetrate deeper but risks damaging the channel floor.

- Shoulder Diameter: Larger shoulders increase heat input, improving fusion but risking overheating and material softening.

- Tool Material: Use high-strength materials (e.g., H13 tool steel or tungsten carbide) to withstand high temperatures and friction.

(2) What's the main Parameters for the FSW process?

- Rotational Speed: Higher speeds (e.g., 800–1500 RPM) generate more heat but may cause excessive plasticization of aluminum.

- Travel Speed: Slower speeds (e.g., 50–150 mm/min) ensure thorough mixing but increase cycle time. Balance with rotational speed to achieve optimal heat input (e.g., a speed ratio of 10:1).

- Axial Force: Adequate downward force (e.g., 5–10 kN) ensures tool penetration and tight bonding, but excessive force may deform the channel.

(3) What's the key point for the FSW cold plate Welding Quality Control?

- Defect Prevention:

- Avoid voids, tunnel defects, or flash (extruded material) by optimizing tool geometry and speed.

- Use backing plates to support the joint and prevent sagging during welding.

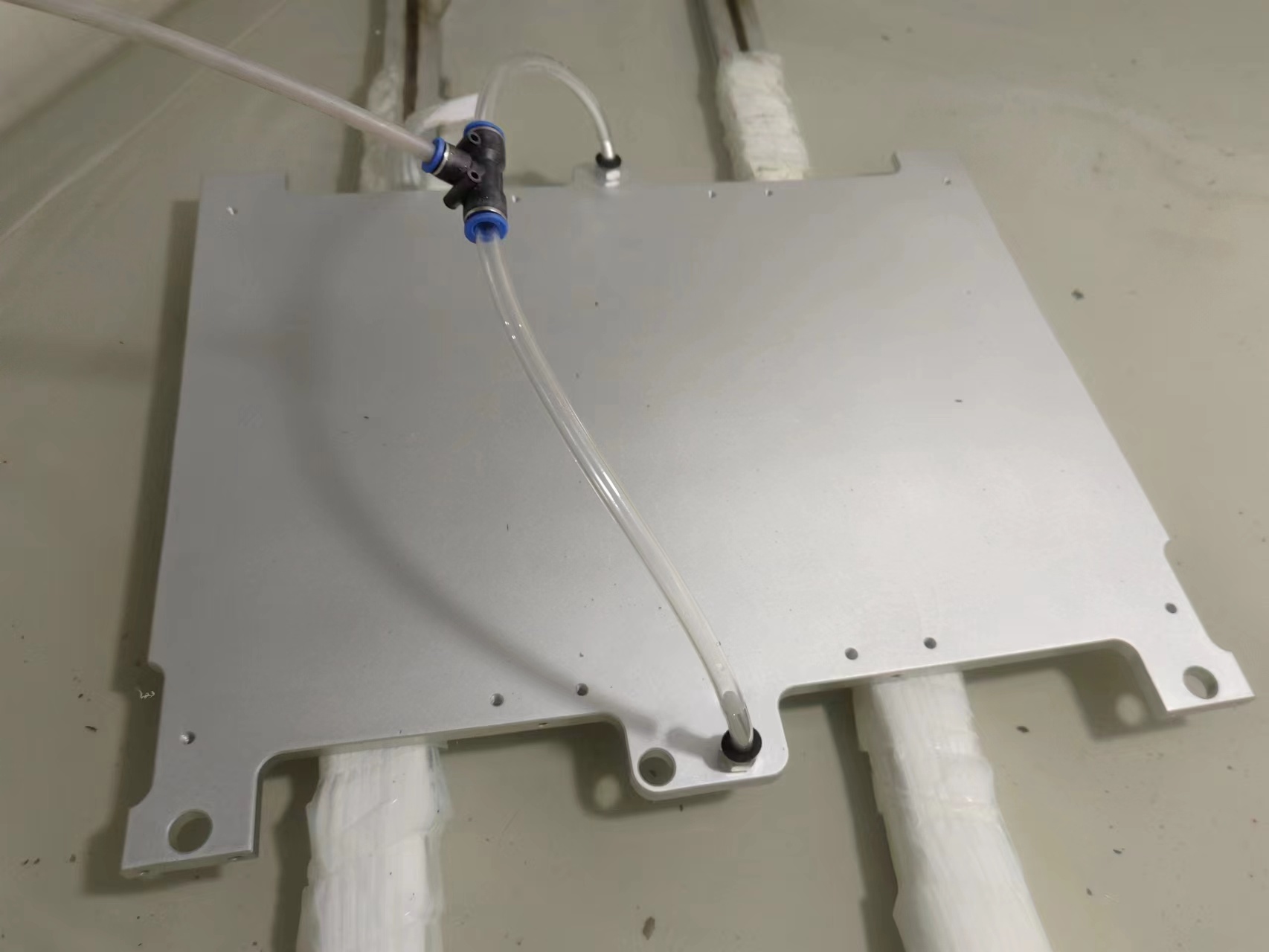

- Post-Weld Inspection:

- Perform dye penetrant testing or X-ray imaging to detect internal flaws.

- Conduct leak testing (e.g., pressure testing with water or nitrogen at 1–3 bar) to ensure no fluid leakage.

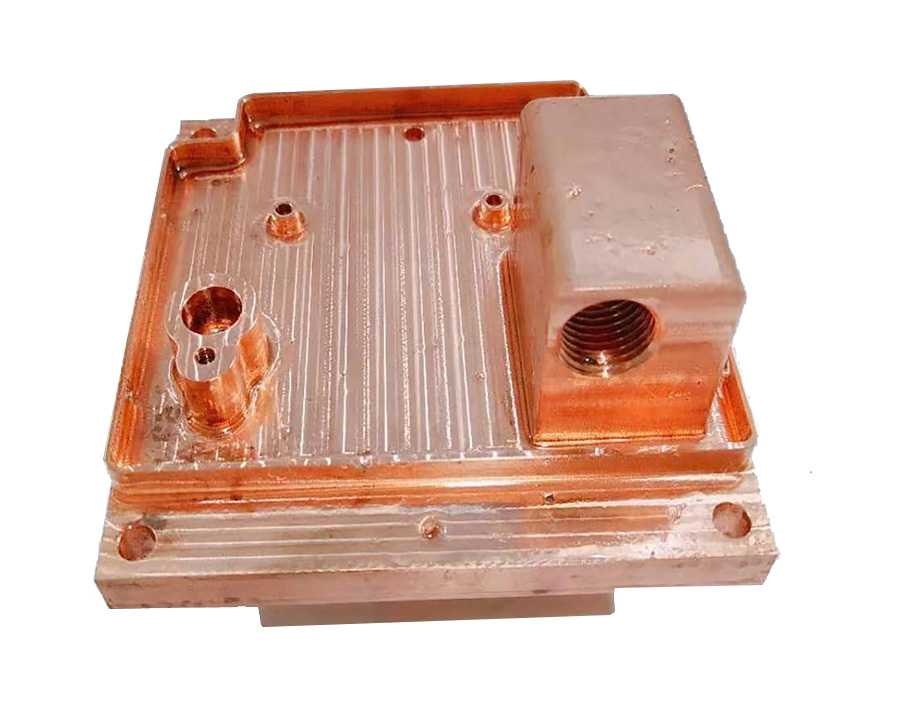

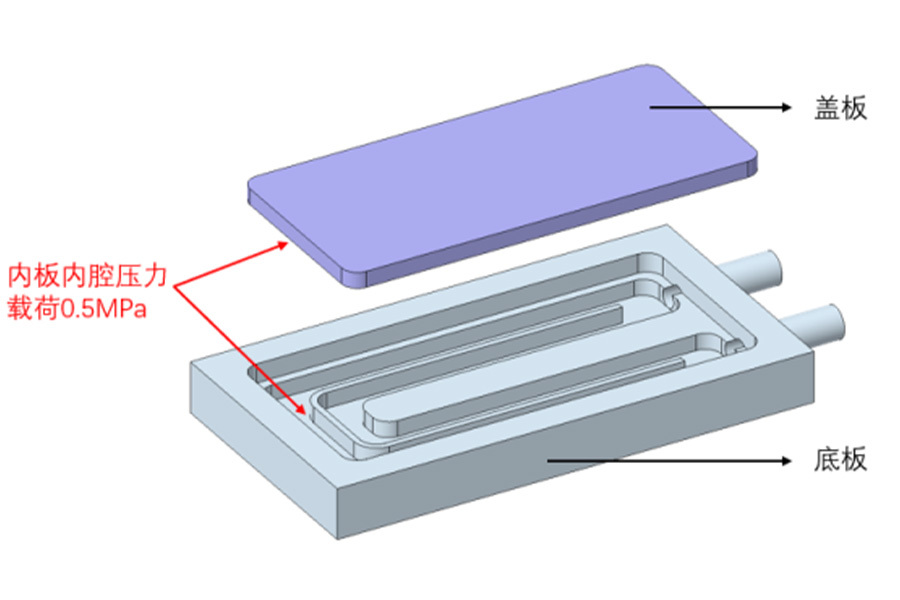

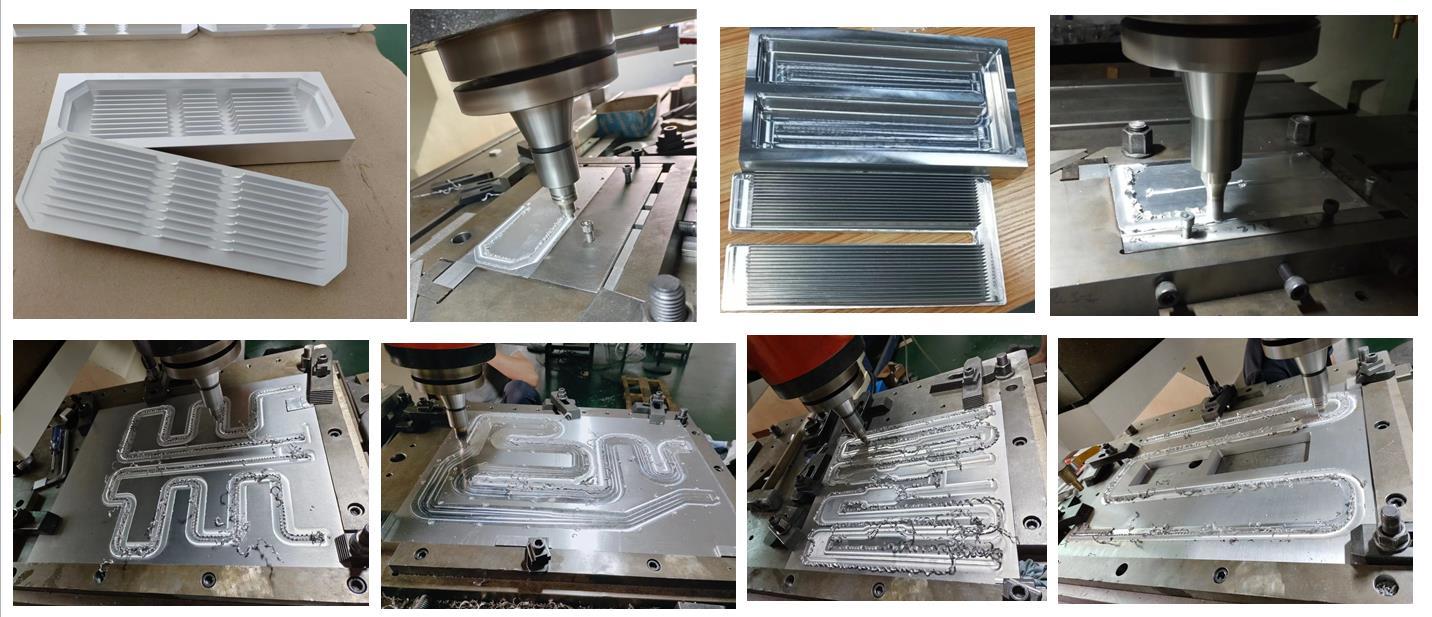

3. Fluid Channel Design and Machining

- Channel Geometry:

- Use rectangular or trapezoidal grooves (width: 2–5 mm, depth: 1–3 mm) for high heat flux areas (e.g., laser diode arrays or IGBT modules).

- Optimize channel spacing (5–10 mm) to balance flow resistance and heat dissipation.

- Avoid sharp bends in channels to reduce pressure drop and turbulence.

- Machining Precision:

- Use CNC milling or chemical etching for high-precision channel dimensions (tolerance: ±0.05 mm).

- Ensure smooth channel surfaces (Ra ≤ 3.2 μm) to minimize fluid resistance and enhance heat transfer.

4. Structural Strength and Thermal Interface

- Bonding Integrity:

- The FSW joint must withstand mechanical stress (e.g., from clamping) and thermal cycling without delamination.

- Ensure the weld depth fully penetrates the channel floor (e.g., 0.5–1 mm into the base plate) to form a robust seal.

- Thermal Interface Materials (TIMs):

- Apply high-conductivity TIMs (e.g., thermal grease or phase-change materials, λ ≥ 5 W/m·K) between the cold plate and heat source (e.g., laser modules) to minimize contact resistance.

5. Post-Processing and Surface Treatment

- Deburring and Cleaning:

- Remove burrs from channel edges and weld flash to prevent fluid blockages.

- Use ultrasonic cleaning to remove machining debris and oil residues.

- Corrosion Resistance:

- Apply anodizing (thickness: 5–25 μm) or electroplating (e.g., nickel or silver) to protect the aluminum surface from coolant corrosion (especially for non-deionized water).

- Ensure the surface treatment does not compromise thermal conductivity (e.g., thin anodization layers for high heat flux areas).

6. Testing and Validation for the liquid cold plate is indispensable process.

- Thermal Performance Testing:

- Use infrared thermography to measure temperature distribution under simulated load (e.g., power density ≥500 W/cm²).

- Verify that the cold plate maintains the laser system’s temperature within ±1°C of the target (e.g., 20–25°C).

- Reliability Testing:

- Subject the cold plate to pressure cycling (e.g., 10,000 cycles between 0.5–2 bar) and thermal cycling (-20°C to 80°C) to assess fatigue resistance.

- Validate long-term durability in corrosive environments (e.g., using coolant mixtures with ethylene glycol).

7. Process Consistency and Scalability

- Mass Production Control:

- Use automated FSW machines with precise parameter control (e.g., servo-driven systems) to ensure repeatability across batches.

- Implement statistical process control (SPC) for key parameters (e.g., weld depth, pressure) to reduce variability.

- Cost Optimization:

- Balance FSW tool lifespan (replace every 500–1000 welds for aluminum) with production efficiency to minimize tooling costs.

Summary of Key Challenges for the FSW process liquid cold plate:

- Achieving defect-free FSW joints in thin-walled aluminum structures.

- Balancing channel efficiency (for heat transfer) and fluid pressure drop.

- Ensuring long-term reliability under high-power, high-cycle operation.

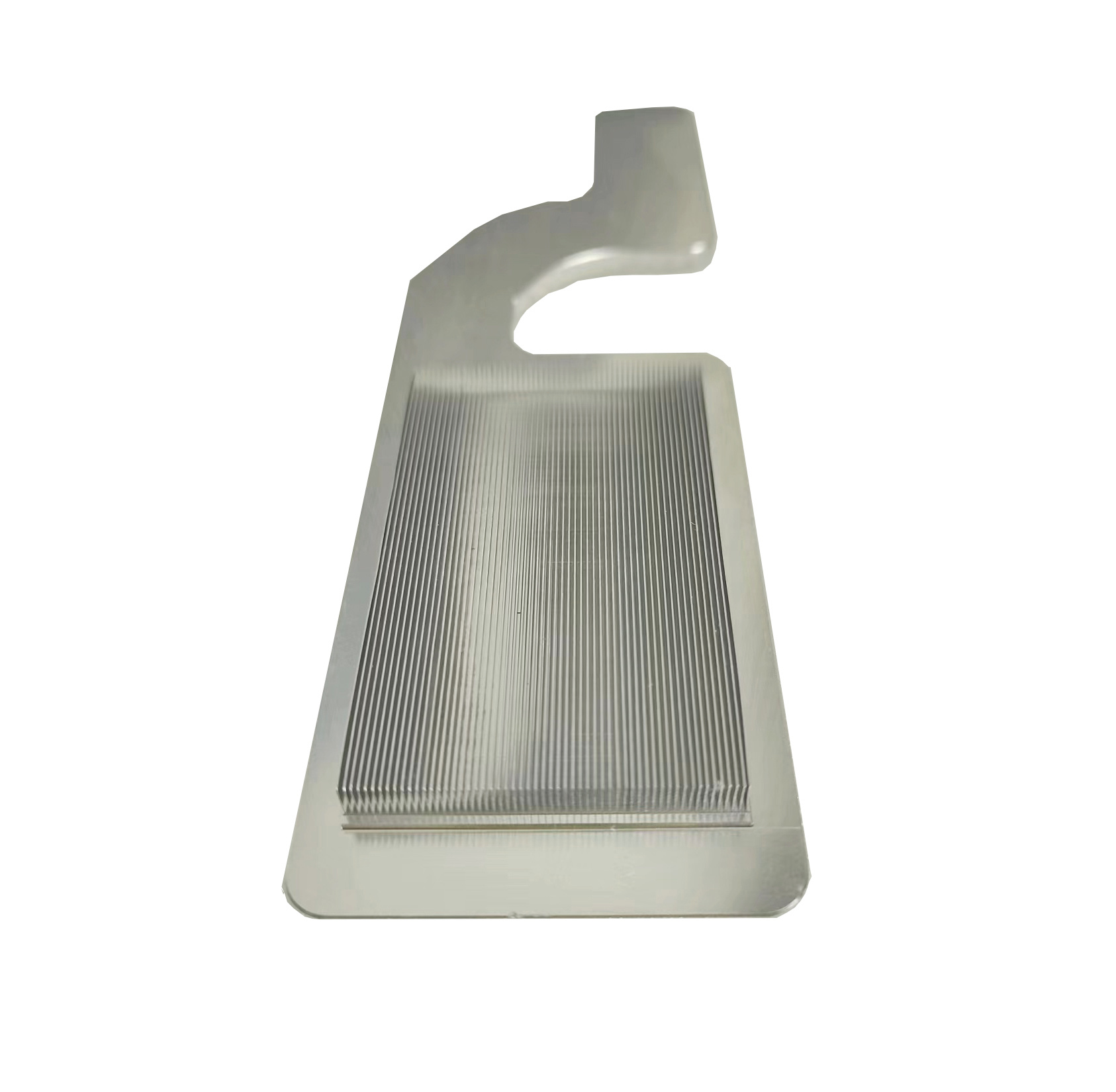

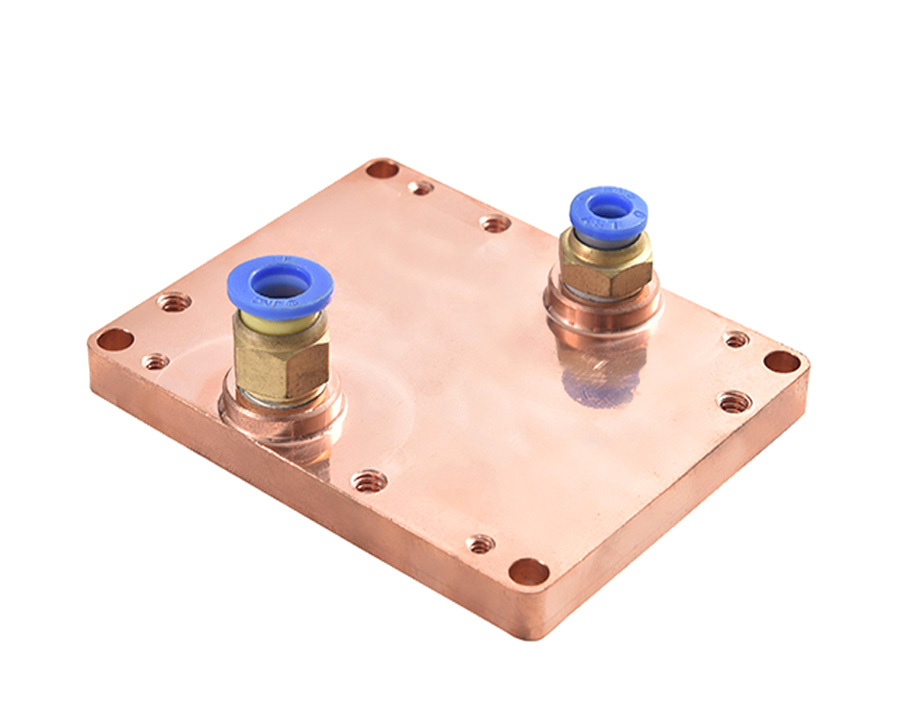

fibre laser liquid cooling Aluminum FSW liquid cold plate

Contact Us

Classification